A kind of preparation method and product of high thermal conductivity deformed aluminum alloy

A technology of deforming aluminum alloys and high thermal conductivity, applied in the field of aluminum alloys, can solve the problems of more strength decline and less stable performance, and achieve the effect of eliminating segregation, good grain orientation, and good precipitation phase orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

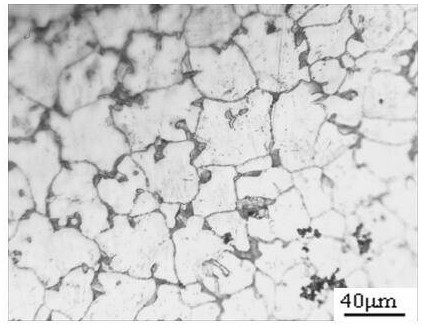

Embodiment 1

[0029] Preparation of High Thermal Conductivity Deformed Aluminum Alloy

[0030] (1) Solution treatment: heat the Al-5Zn-2Mg-1.5Cu alloy ingot at a rate of 50°C / h to 350°C and keep it for 1.5h, then heat it up to 460°C for 0.5h and keep it for 7h, and finally in the room Warm water quenching;

[0031] (2) Extrusion treatment: heat the Al-5Zn-2Mg-1.5Cu alloy ingot after step (1) to 440°C, press the extrusion ratio to be 20, and the extrusion speed to be 10mm / s for extrusion treatment, Obtain Al-5Zn-2Mg-1.5Cu alloy extruded rods;

[0032] (3) Aging treatment: heating the Al-5Zn-2Mg-1.5Cu alloy extruded rod obtained in step (2) to 140° C., keeping it warm for 8 hours, and then cooling to room temperature;

[0033] (4) Pre-deformation treatment: carry out 8% pre-compression deformation treatment along the extrusion direction to the Al-5Zn-2Mg-1.5Cu alloy extruded bar after step (3);

[0034] (5) Annealing treatment: heat the extruded 7075 alloy rod treated in step (4) to 180° C...

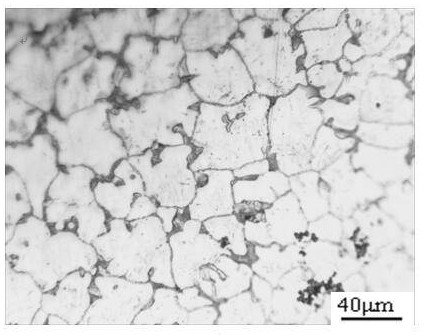

Embodiment 2

[0036] Preparation of High Thermal Conductivity Deformed Aluminum Alloy

[0037] (1) Solution treatment: heat the Al-6Zn-2Mg-1.5Cu alloy ingot at a rate of 50°C / h to 350°C and keep it for 2 hours, then heat it up to 460°C for 1.5 hours and keep it for 8 hours. Quenching;

[0038] (2) Extrusion treatment: heat the Al-6Zn-2Mg-1.5Cu alloy ingot after step (1) to 450°C, press the extrusion ratio to be 25, and the extrusion speed to be 13mm / s for extrusion treatment, Obtain Al-6Zn-2Mg-1.5Cu alloy extruded rod;

[0039] (3) Aging treatment: heating the extruded Al-6Zn-2Mg-1.5Cu alloy rod obtained in step (2) to 150° C., keeping it warm for 10 hours, and then cooling to room temperature;

[0040] (4) Pre-deformation treatment: the Al-6Zn-2Mg-1.5Cu alloy extruded bar after step (3) is subjected to 9% pre-compression deformation treatment along the extrusion direction;

[0041] (5) Annealing treatment: heat the Al-6Zn-2Mg-1.5Cu alloy extruded bar after step (4) to 190°C, keep it for...

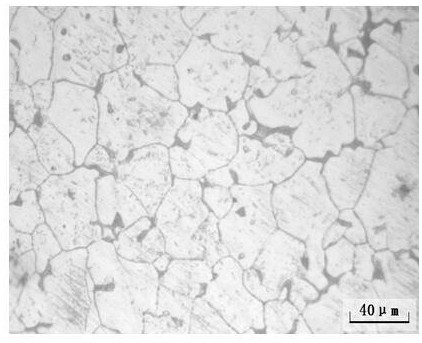

Embodiment 3

[0043] Preparation of High Thermal Conductivity Deformed Aluminum Alloy

[0044] (1) Solution treatment: heat up the Al-6Zn-3Mg-2Cu alloy ingot at a rate of 80°C / h to 400°C and keep it for 8 hours, then heat it up to 460°C for 2 hours and keep it for 8 hours, and finally cool it in water at room temperature ;

[0045] (2) Extrusion treatment: heat the Al-6Zn-3Mg-2Cu alloy ingot processed in step (1) to 460°C, press the extrusion ratio to be 20, and the extrusion speed to be 10mm / s for extrusion treatment to obtain Al-6Zn-3Mg-2Cu alloy extrusion rod;

[0046] (3) Aging treatment: heating the extruded Al-6Zn-3Mg-2Cu alloy rod obtained in step (2) to 160° C., keeping it warm for 8 hours, and then cooling to room temperature;

[0047] (4) Pre-deformation treatment: carry out 8% pre-compression deformation treatment along the extrusion direction to the Al-6Zn-3Mg-2Cu alloy extruded bar after step (3);

[0048] (5) Annealing treatment: heat the extruded Al-6Zn-3Mg-2Cu alloy bar a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com