Fayalite type slag desiliconization method

A fayalite and slag technology, applied in the field of mineral engineering, can solve the problems of low iron recovery rate, difficult separation of metal ions, and secondary slag generation, and achieve high silicon oxide removal rate, simple process flow, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

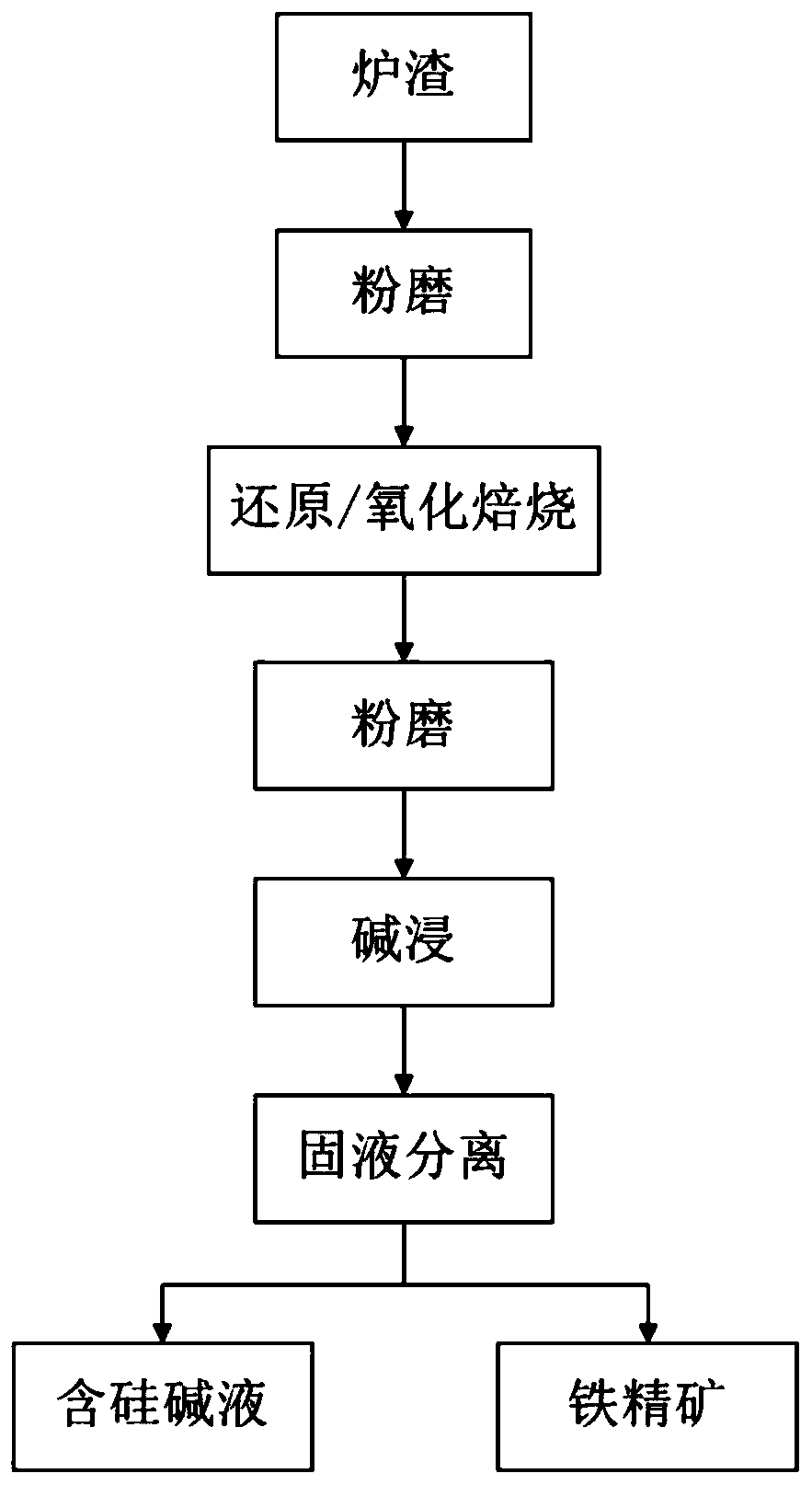

Method used

Image

Examples

specific Embodiment approach

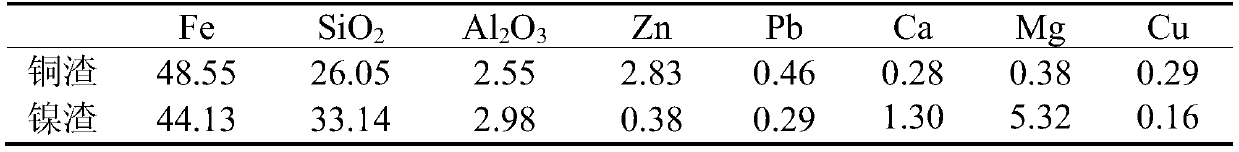

[0040] The main chemical components of the copper slag and nickel slag used in this embodiment are shown in Table 1.

[0041] Table 1 Chemical composition of copper slag and nickel slag (wt.%).

[0042]

specific Embodiment approach 1

[0044] Step S1, grinding the slag, the slag is copper slag, and grinding the copper slag until the particle size d0.5 is about 33.12 μm;

[0045] Step S2, oxidizing and roasting the ground copper slag, adding it to the roasting furnace, introducing an oxidizing atmosphere, and oxidizing and roasting at a temperature of 1000 ° C for 60 minutes, so as to completely decompose ferrous silicate into iron oxide and silicon oxide, and obtain activation clinker;

[0046] Step S3: Grinding the activated clinker until the particle size d0.5 is about 31.32 μm, and then adding it into the lye for alkaline leaching. In this example, sodium hydroxide alkali solution is used to desilicate the oxidized roasted clinker by alkali leaching, the leaching temperature is 100°C, the liquid-solid ratio is 8, the sodium hydroxide concentration is 160g / L, and the leaching time is 120min;

[0047] Step S4, the solid-liquid separation of the ore pulp obtained by alkali leaching is carried out to obtain si...

specific Embodiment approach 2

[0049] Step S1, grinding the slag, the slag is copper slag, and grinding the copper slag until the particle size d0.5 is about 33.12 μm;

[0050] Step S2, reducing and roasting the ground copper slag, now adding carbon powder to the copper slag, the molar ratio of Fe and C in the nickel slag is 1:2, after mixing and grinding, add to the roasting furnace and pass Reducing atmosphere, and reducing roasting at 1200°C for 60 minutes to completely decompose ferrous silicate into metallic iron and silicon oxide, and obtain activated clinker;

[0051] Step S3: Grinding the activated clinker until the particle size d0.5 is about 30.68 μm, and then adding it into the lye for alkaline leaching. In this example, sodium hydroxide alkaline solution is used to desilicate the oxidized roasted clinker by alkaline leaching, the leaching temperature is 90°C, the liquid-solid ratio is 5, the sodium hydroxide concentration is 160g / L, and the leaching time is 120min;

[0052] Step S4, the solid-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com