Laser scanning method for coaxially feeding powder

A laser scanning and coaxial powder feeding technology, applied in the field of additive manufacturing, can solve the problems of insufficient partition dispersion and energy concentration, avoid heat and stress concentration, prevent heat and stress concentration, and reduce the probability of component deformation and cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A laser scanning method for coaxial powder feeding, comprising the following steps:

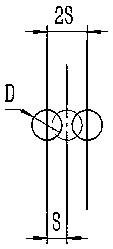

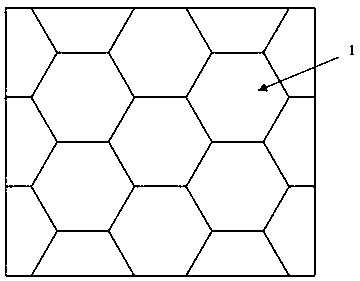

[0073] S1. Obtain and identify the contour file of the cross-section of the workpiece to be processed layer by layer. In the area of the contour file of each layer, the same regular hexagon is evenly arranged to partition; the diameter of the inscribed circle of the regular hexagon is 36mm.

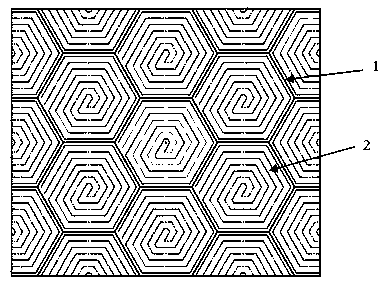

[0074] S2. Planning a scan path 2 in each of the partitions, and then deleting a partition line of the partition; the scan path 2 is composed of a forward scan path and a backfill scan path. Such as Figure 5 shown.

[0075] Planning a first polygon within said polygon 1 for partitioning, said first polygon being the same as said polygon for partitioning; planning a second polygon within said polygon 1 for partitioning ;

[0076] The forward scanning path is: starting from the end point A of the first polygon, scanning clockwise in a regular hexagonal shape with centripetal equidistant helica...

Embodiment 2

[0085] A laser scanning method for coaxial powder feeding in this embodiment is basically the same as Embodiment 1, the only difference is that the scanning distance is 3mm, the scanning step is 6mm, the width of the melting channel is 4.3mm, and the overlap ratio 30%; the diameter of the inscribed circle of the regular hexagon used for partitioning is 30mm, the diameter of the inscribed circle of the first polygon is 24mm, and the diameter of the inscribed circle of the second polygon is 3mm; the laser scanning is performed first A laser scan within the partition is performed after the bounding box scan.

[0086] Observation of the metal component of this embodiment shows that the surface is smooth, with little deformation and no cracks.

Embodiment 3

[0088] A laser scanning method for coaxial powder feeding in this embodiment is basically the same as in Embodiment 1, except that the scanning distance is 9mm, the scanning step is 18mm, the width of the melting channel is 15mm, and the overlap rate 40%; the diameter of the inscribed circle of the regular hexagon used for partitioning is 90mm, the diameter of the inscribed circle of the first polygon is 72mm, and the diameter of the inscribed circle of the second polygon is 9mm;

[0089] The forward scanning path is as follows: starting from a point on the second polygon, spirally scanning outwards equidistantly in the shape of a regular hexagon counterclockwise, and ending at endpoint A on the first polygon.

[0090] The backfill scanning path is as follows: start from point B that is flush with the end point A, scan clockwise in the shape of a regular hexagon with a centripetal equidistant spiral, and backfill until it connects with the starting point of the forward scanning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com