A treatment method for high-concentration salt-containing organic waste liquid

A high-concentration salt-containing and organic waste liquid technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the complex domestication process of halophilic bacteria, high energy consumption, and boiler crystallization corrosion and other problems, to achieve the effect of improving electron beam irradiation technology, high efficiency of degradation and removal, and simple treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

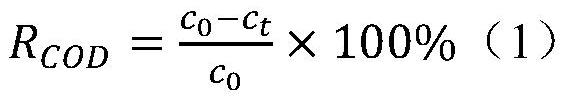

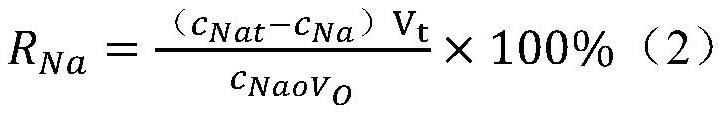

[0017] Effects of pH of acid regulatory waste liquid and COD removal rate and chloride recovery rate in high concentrations containing salt organic waste liquid

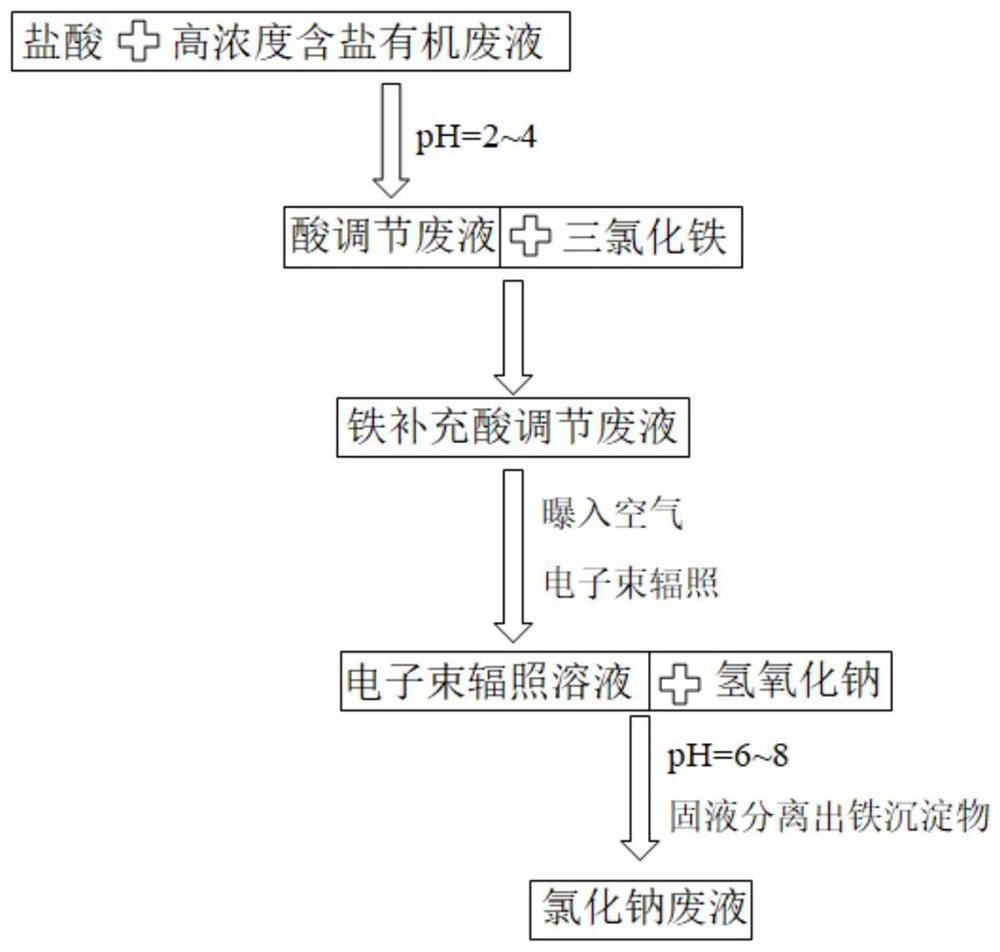

[0018] Treatment of high concentrations containing salt organic waste: figure 1 As shown, the pH of the high concentration-containing organic waste liquid is adjusted by hydrochloric acid, so that the pH is equal to 1, 1.5, 1.8, 2, 3, 4, 4.2, 4.8, 5, acid regulating waste liquid; weigh trichloride The iron is added to the acid regulating waste liquid, stirred to ferricide completely dissolve, iron supplement acid regulating waste liquid, the concentration of ferricide in the waste liquid is 0.5 mol / L; supply to iron supplementate acid regulating waste liquid continuous Exposed air, while the iron supplement acid regulating waste is electron beam irradiation treatment (the electron line accelerator, IS05 type of the same party Weiwei Technologies Co., Ltd.), and the irradiation dose reaches 20 kGy to stop irradiation, a...

Embodiment 2

[0028] Effect of TCC Concentration on COD Removal Rate and Sodium Chloride Recovery Rate in High Concentration Salt Soil

[0029]Treatment of high concentrations containing saline organic waste: Adjusting the pH of a high concentration of saline organic waste liquid to make it pH equal to 4, obtained acid regulating waste liquid; The iron chloride is completely dissolved, and the iron supplementation of the iron is added to the iron tetrachloride concentration of 0.25, 0.35, 0.45, 0.5, 1, 1.5, 1.55, 1.65, 1.75mol / L; The air is continuously exposed in the acid regulating waste, and the iron supplement acid regulating the waste liquid is electron beam irradiation treatment. When the irradiation dose reaches 40 kGy, the irradiation is stopped, and the electron beam irradiation solution is obtained; sodium hydroxide, stir, and regulate the solution pH. To 7, the trivalent iron ion and ferrium ions are completely precipitated, and the solid-liquid separation is recovering iron precip...

Embodiment 3

[0035] Effect of Electron Beam Radiosity on COD Removal Rate and Sodium Chloride Rehabilitation Rate in High Concentration Salt Organic Watch

[0036] Treatment of high concentrations containing saline organic waste: Adjusting the pH of a high concentration of saline organic waste liquid to make it pH equal to 4, obtained acid regulating waste liquid; The iron tetrachloride is completely dissolved, the iron supplement acid regulating waste liquid is 1.5 mol / L in the waste liquid; the iron is continuously exposed to the iron supplement acid regulating liquid, and the iron supplement acid regulates the iron The liquid is irradiated with an electron beam irradiation treatment, and the irradiation dose reaches 10 kgy, 15 kgy, 18 kgy, 20 kgy, 40 kgy, 60 kgy, 62kGy, 65kGy, 70kGy to stop irradiation, and electron beam irradiation solution; sodium hydroxide, stir, regulate the solution pH To 8, the trivalent iron ion and ferrium ions are completely precipitated, and the solid-liquid sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com