Liquid hazardous chemical substance leakage bridge deck sensing detection early-warning device

A technology of inductive detection and early warning device, applied in material resistance, signal transmission system, instruments, etc., can solve the problems of delay, difficult to repair and replace, and difficult to realize the method of drainage pipeline detection, and achieves the benefits of application promotion, installation and replacement. The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The above solution will be further described below in conjunction with specific embodiments. These examples are provided to illustrate the present invention and not to limit the scope of the present invention.

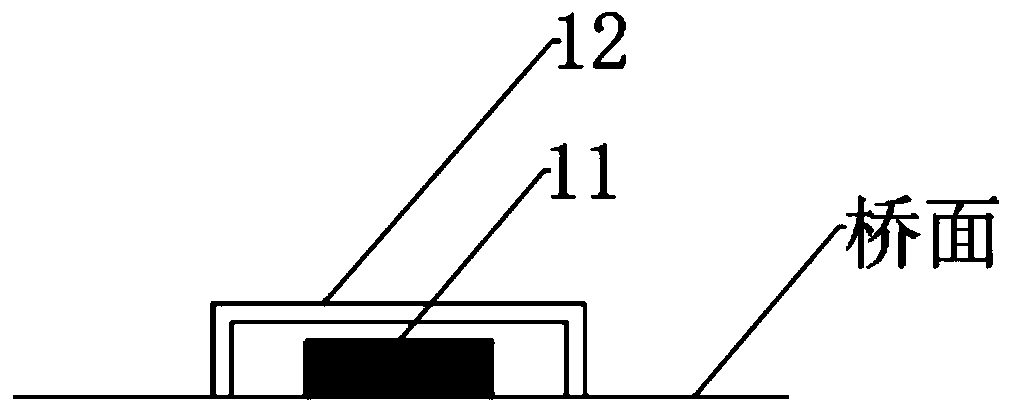

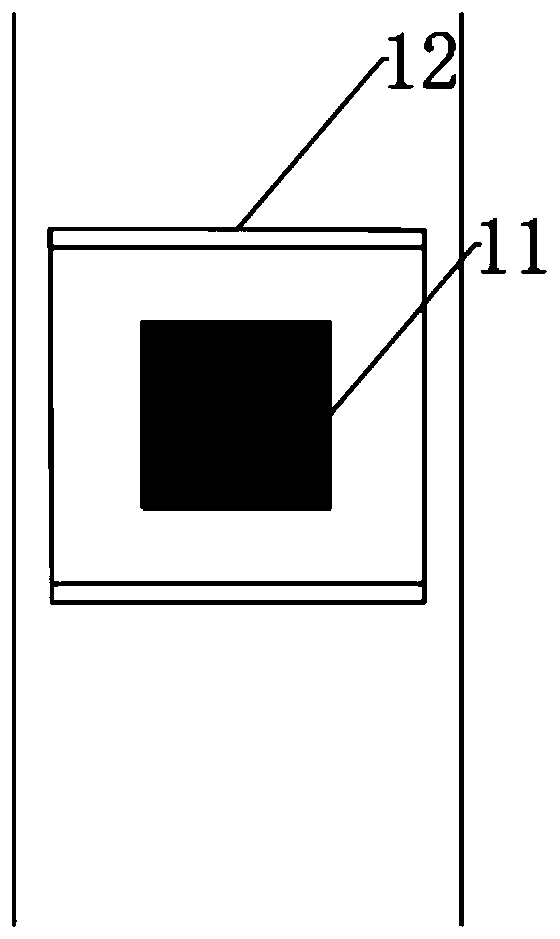

[0021] As shown in FIG. 1 , the bridge deck induction detection and early warning device for leakage of liquid hazardous chemicals according to the present invention includes a primary detection and early warning unit 1 and a secondary detection and early warning unit 2;

[0022] The primary detection and early warning unit 1 includes a liquid dielectric constant detection sensor 11, a first storage module pre-stored with normal rain and snow dielectric constant index values, a first CPU processing module, a first wireless communication module and a first protective shell 12 ;

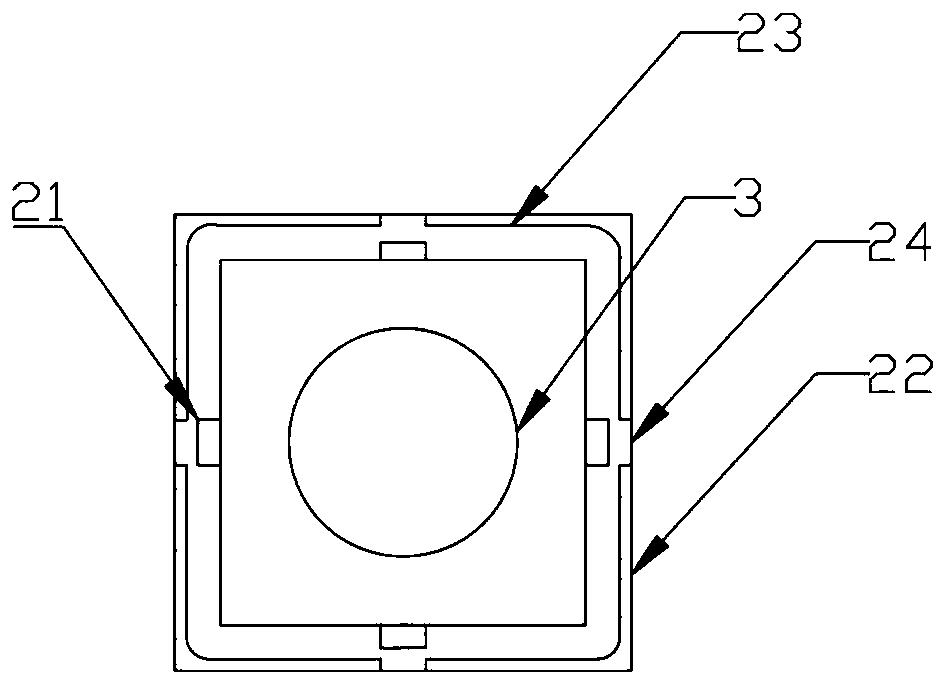

[0023] The secondary detection and early warning unit includes a liquid conductivity sensor, a pH value detection sensor, a secondary detection and early warning unit sensor group 21 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com