Application of ultrathin silicon nitride nanopore membrane in reverse electrodialysis power generation and device

A technology of reverse electrodialysis and silicon nitride thin film, applied in the direction of generators, generators/motors, electrical components, etc. that convert kinetic energy into electrical energy, can solve the problems of power generation efficiency limited by physical size, etc., and achieve good application prospects , good corrosion resistance, the effect of broadening the scope of application of acid and alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

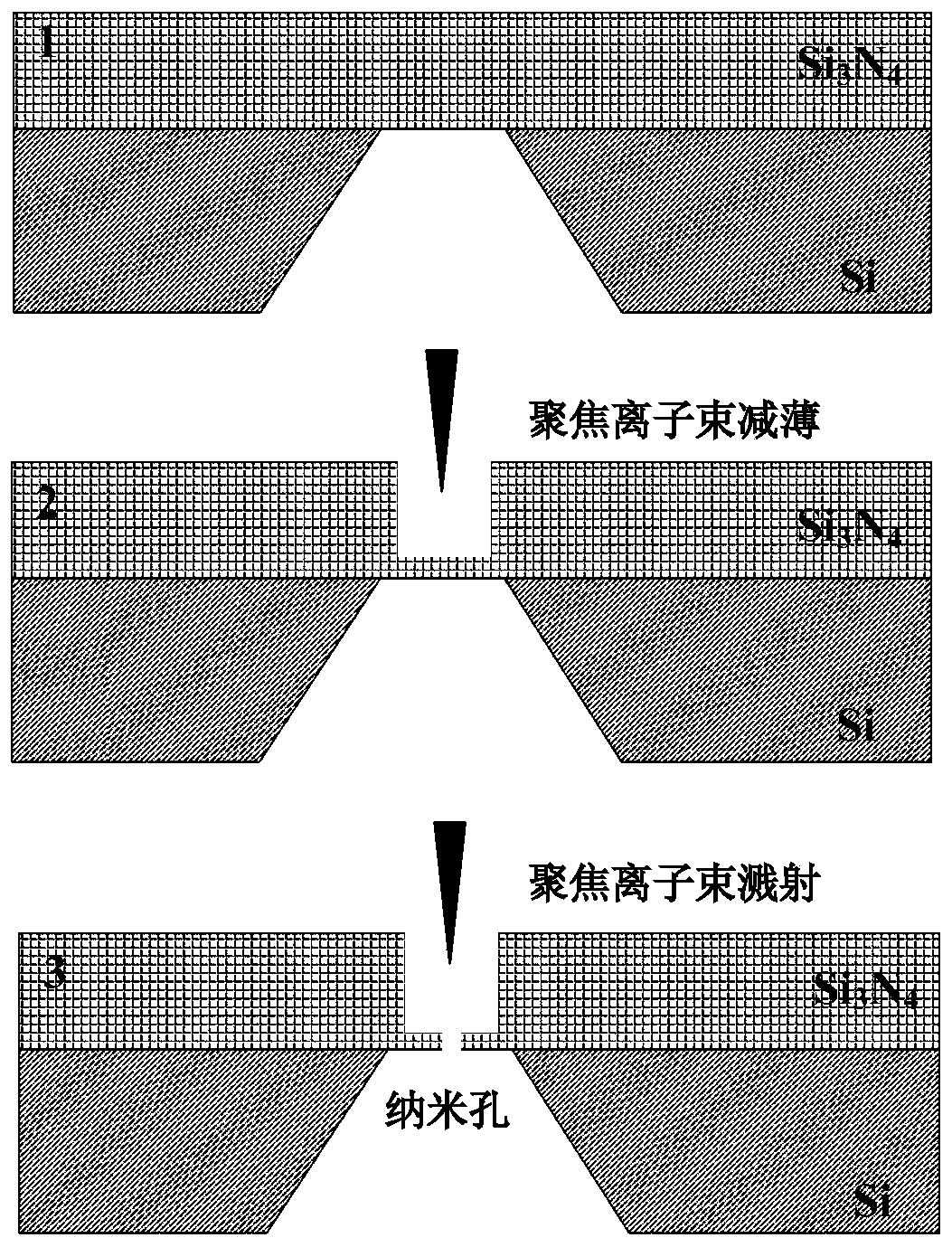

[0024] like figure 1 As shown, the manufacturing method of the ultra-thin silicon nitride nanoporous membrane described in this embodiment is: first, a silicon wafer with a thickness of 300 μm is polished on both sides; 100nm thick silicon nitride film; and then use tetramethyl ammonium hydroxide directional etching to etch a 100×100μm window on the silicon wafer substrate, thus forming a self-supporting silicon nitride film, and then use focused ion beam on the Thinning is carried out on the self-supporting silicon nitride film, the thinning area is 1-5μm circular, the thickness of the thinning area is controlled at 5-20nm, and finally the focused ion beam is used to sputter in the thinning area to process nanopores with a diameter of 20-100nm structure.

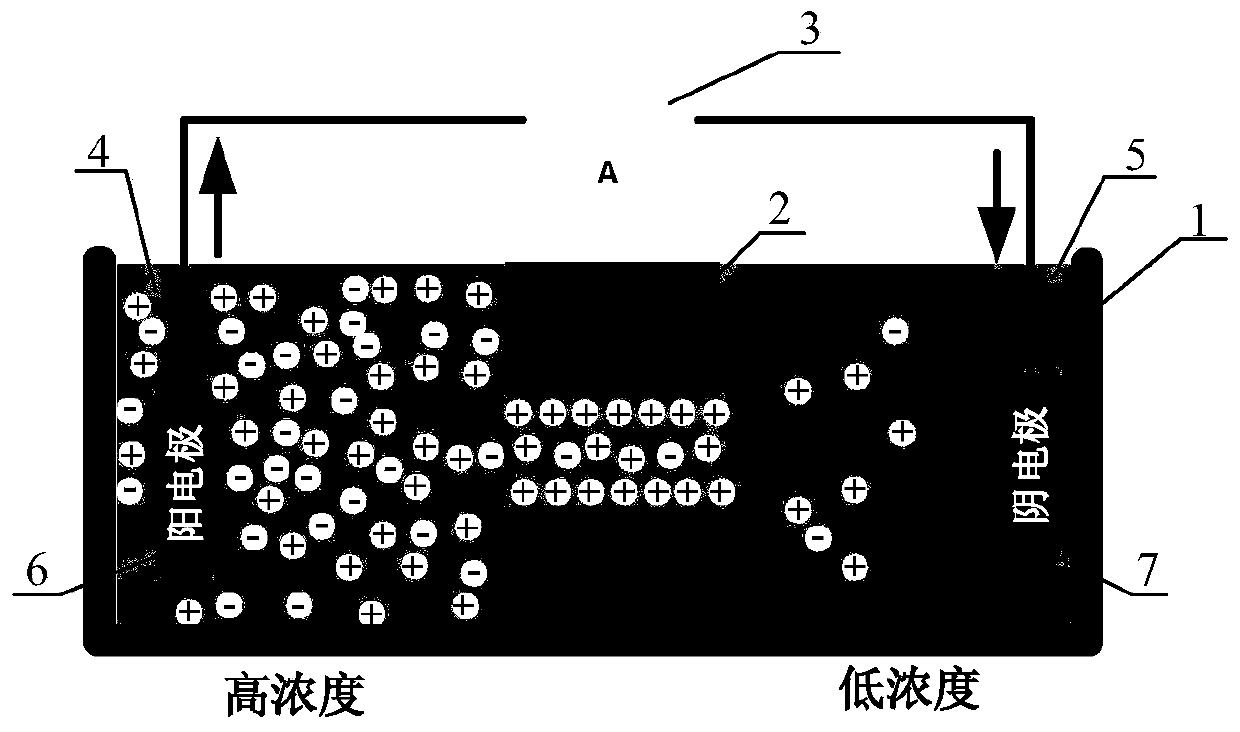

[0025] figure 2 It is a schematic diagram of the application of silicon nitride nanopores in reverse electrodialysis power generation. The device is used for a container 1 containing a salt solution, and the container is...

Embodiment 2

[0029] Generating device and generating process are exactly the same as embodiment 1, just changed the following parameters in the generating device:

[0030] The concentration of the low-concentration potassium chloride solution in the device was fixed at 10 -4 mol / L, change the concentration of high-concentration potassium chloride in turn: 0.001mol / L, 0.01mol / L, 0.1mol / L and 1mol / L. And measure the I-V curve successively to obtain the power density of silicon nitride nanopore power generation (porosity gets 30%) such as Figure 4 . The results show that with the increase of the salt concentration difference, the power density increases from 3226W / m 2 Increase to 35350W / m 2 .

Embodiment 3

[0032] Generating device and generating process are exactly the same as embodiment 1, just changed the following parameters in the generating device:

[0033] The silicon nitride nanopores in the device were replaced by 40nm, 70nm, 97nm, and 140nm in turn, and the thickness of the silicon nitride film was constant. The I-V curve was measured and the power density was calculated (the porosity was 30%). Get the power density as Figure 5 , it is obvious that the smaller the aperture of the nanopore, the greater the power density obtained. When the silicon nitride nanopore diameter is 46nm, the maximum power density is 61956W / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com