Colorful polylactic acid and glycolide-trimethylene carbonate copolymer composite fiber and preparation method thereof

A methyl carbonate, polylactic acid fiber technology, applied in fiber processing, fiber chemical characteristics, conjugated synthetic polymer rayon, etc., can solve the problem of increasing patient treatment costs, affecting the flexibility of surgical wires, and limiting wide application, etc. problems, to achieve good biodegradation rate, economical applicability, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the purple smooth polylactic acid and glycolide-trimethylene carbonate copolymer composite fiber provided by the embodiment of the present invention comprises the following steps:

[0056] Step S1: Obtain polylactic acid slices and glycolide-trimethylene carbonate copolymer slices respectively; grind the glycolide-trimethylene carbonate copolymer slices into 150-mesh powder under liquid nitrogen cooling conditions, and then Mix evenly with 0.4% Violet No. 2 and 1.2% (polycaprolactone weight phenol) calcium stearate, stand-by as composite fiber cortex composition;

[0057] Step S2: Carry out composite spinning for the polylactic acid chip and glycolide-trimethylene carbonate copolymer powder mixture, so that polylactic acid is in the core layer of the composite fiber, and the purple smooth glycolide-trimethylene carbonate copolymer is The polylactic acid is wrapped with polylactic acid to form the skin layer of the composite fiber, and the purpl...

Embodiment 1

[0088] The ratio of the cross-sectional area of the skin layer to the core layer (with polylactic acid as the core of the composite fiber and the mixture of glycolide-trimethylene carbonate copolymer powder as the skin of the composite fiber) is 20:80,

[0089] The spare polylactic acid / glycolide-trimethylene carbonate copolymer powder mixture is vacuum-dried separately, the drying temperature is 85°C, and the vacuum degree is -0.1MPa. The composite fiber is spun-stretched in one step method, the stretching ratio is 5 times. The monofilament fineness is 2.2dtex (50D / 24f). The spinning process conditions are: the temperature range of the core layer component is 210-220°C, the screw pressure is 10MPa, the spinning speed is 300m / min, the temperature range of the skin layer component is 150-180°C, the screw pressure is 8.0MPa, the spinning The speed is 240m / min, the air is cooled, and the side blowing speed is 5m / min, and the purple smooth polylactic acid / glycolide-trimethylene...

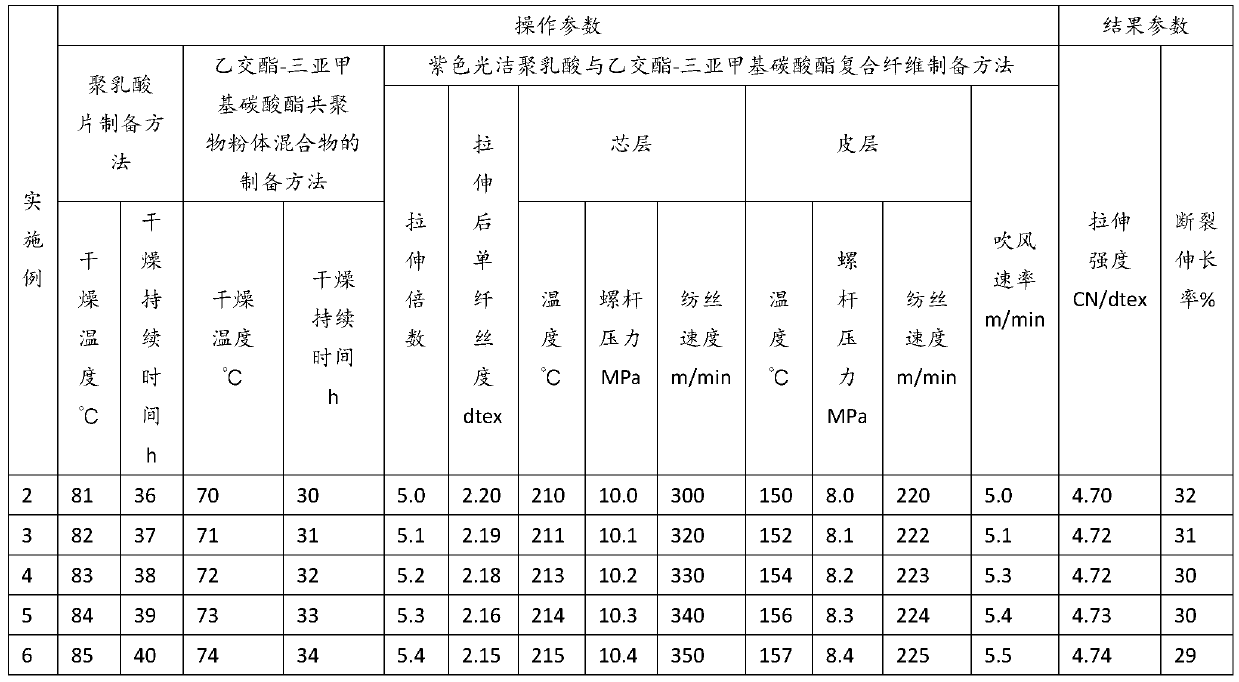

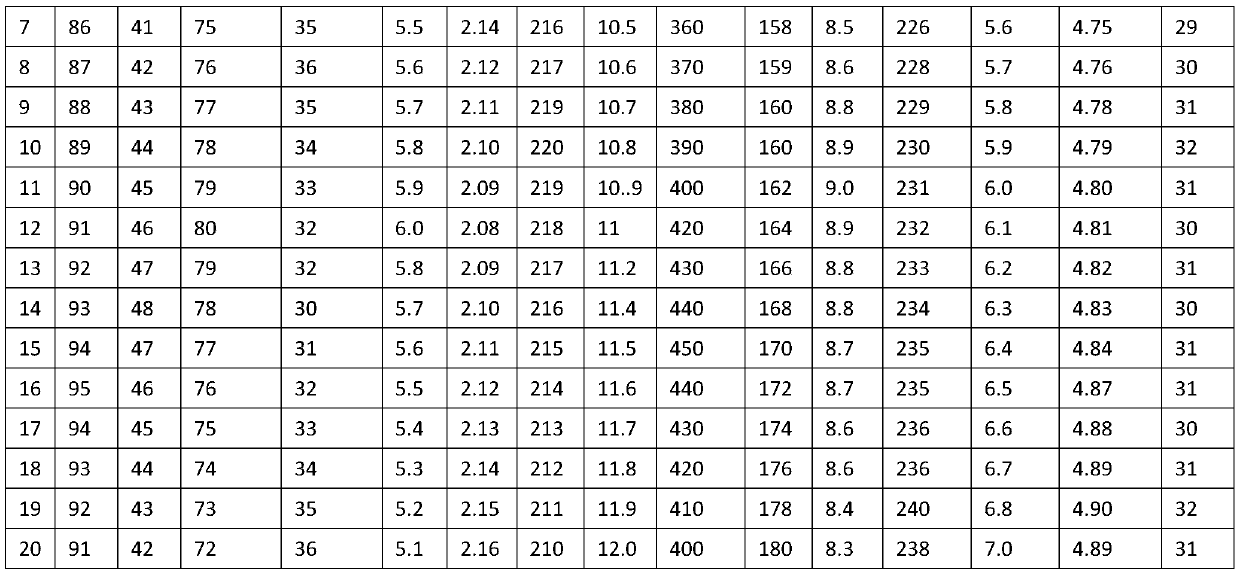

Embodiment 2~20

[0092]

[0093]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com