Alkaline chemical polishing liquid for aluminum alloy

A chemical polishing, aluminum alloy technology, applied in the field of alkaline chemical polishing liquid, can solve problems such as unsafe, unenvironmental protection, and achieve the effect of solving worries, improving production efficiency, and brightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

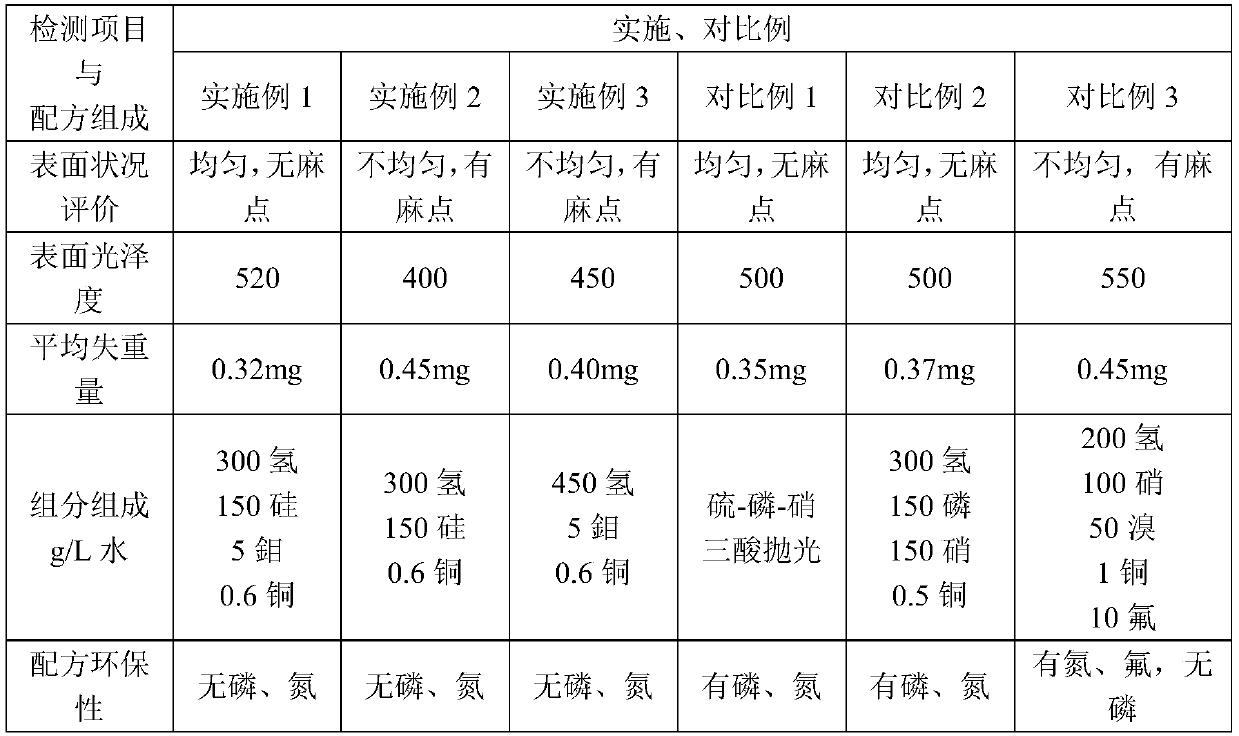

Examples

Embodiment 1

[0029] Polishing solution configuration: Dissolve 300g of sodium hydroxide particles in 1L of water, dissolve 150g of sodium silicate, 5g of sodium molybdate, and 0.6g of copper sulfate in the basic lye successively while the solution is hot, stir evenly, and set aside. The medicaments used are industrial grade reagents.

[0030] Sample preparation: The sample is a 5 series aluminum-magnesium alloy plate provided by a notebook computer accessories factory, the size is 100mm×60mm×2mm, and the surface has been sandblasted.

[0031] Polishing effect detection index: (1) Visually test the surface condition evaluation of the sample after polishing (uniformity, whether there are over-corrosion pits); (2) Use a gloss meter to measure the brightness value of the sample surface. (3) Calculate the weight loss (0.01 mg) of the sample before and after polishing with a mechanical analytical balance. The smaller the weight loss, the better the polishing quality.

[0032] The polishing proc...

Embodiment 2

[0040] Compared with Example 1, the difference of Example 2 is that there is no sodium molybdate oxidation bright component in the polishing liquid configuration.

Embodiment 3

[0042] Compared with Example 1, the difference of Example 3 is that in the polishing liquid configuration, 150g of sodium silicate is replaced by 150g of sodium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com