Aluminum alloy alkaline Sn-Mo conversion liquid and aluminum alloy conversion treatment method

A conversion treatment, aluminum alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of human body and environmental toxicity, achieve good discoloration resistance and corrosion resistance, good industrialization potential, and avoid the effect of acid mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

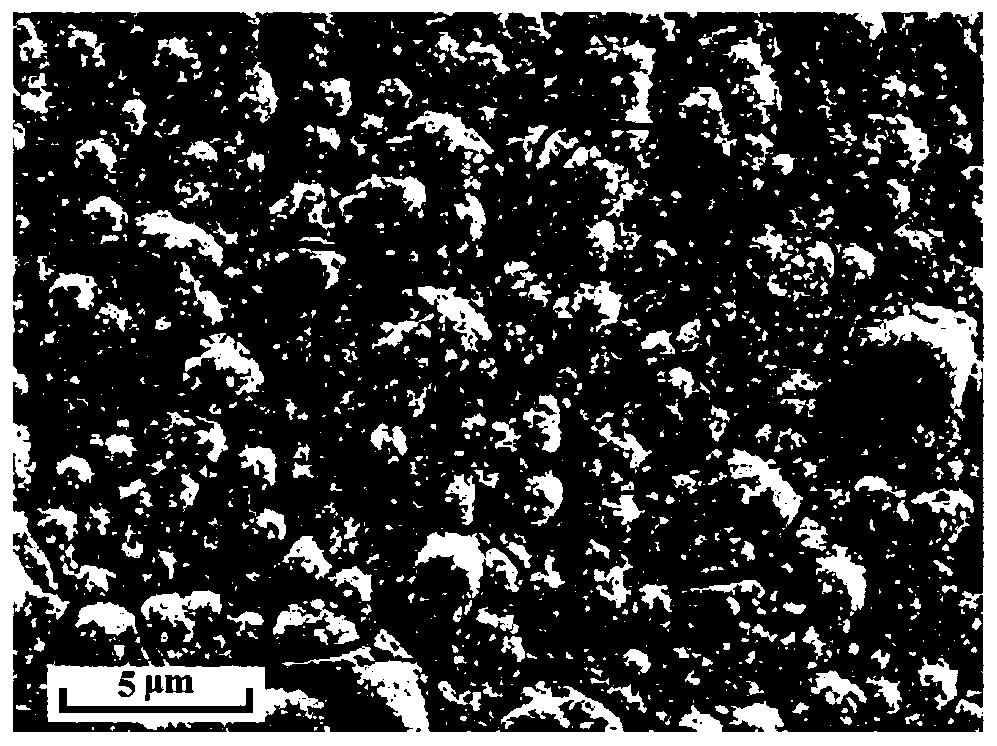

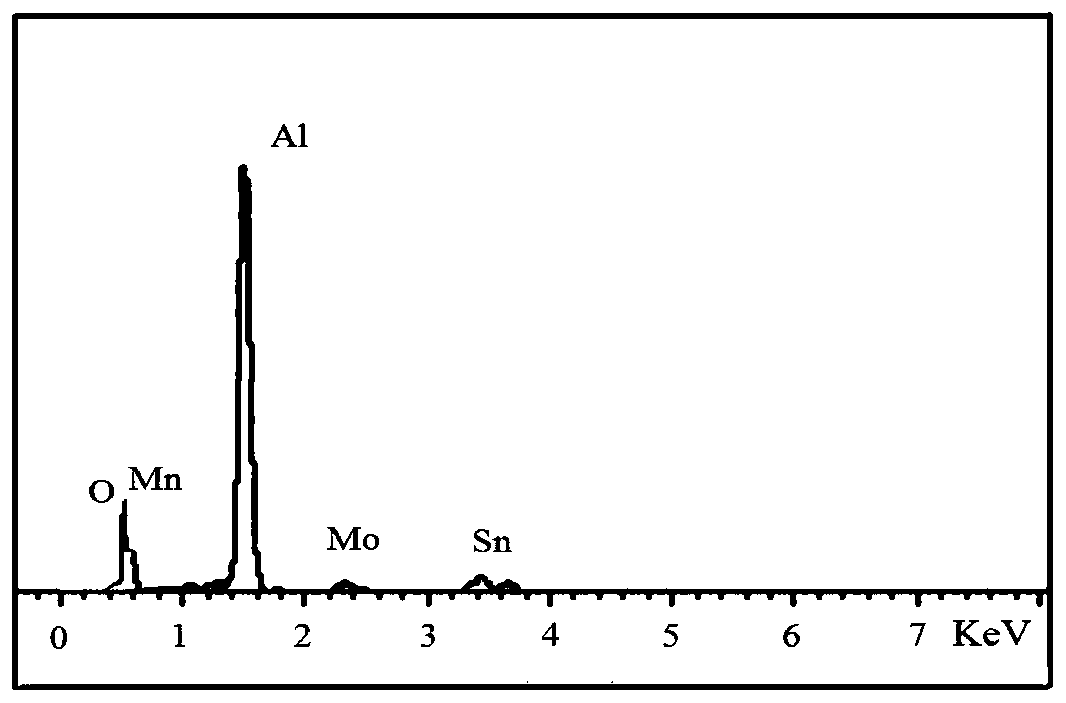

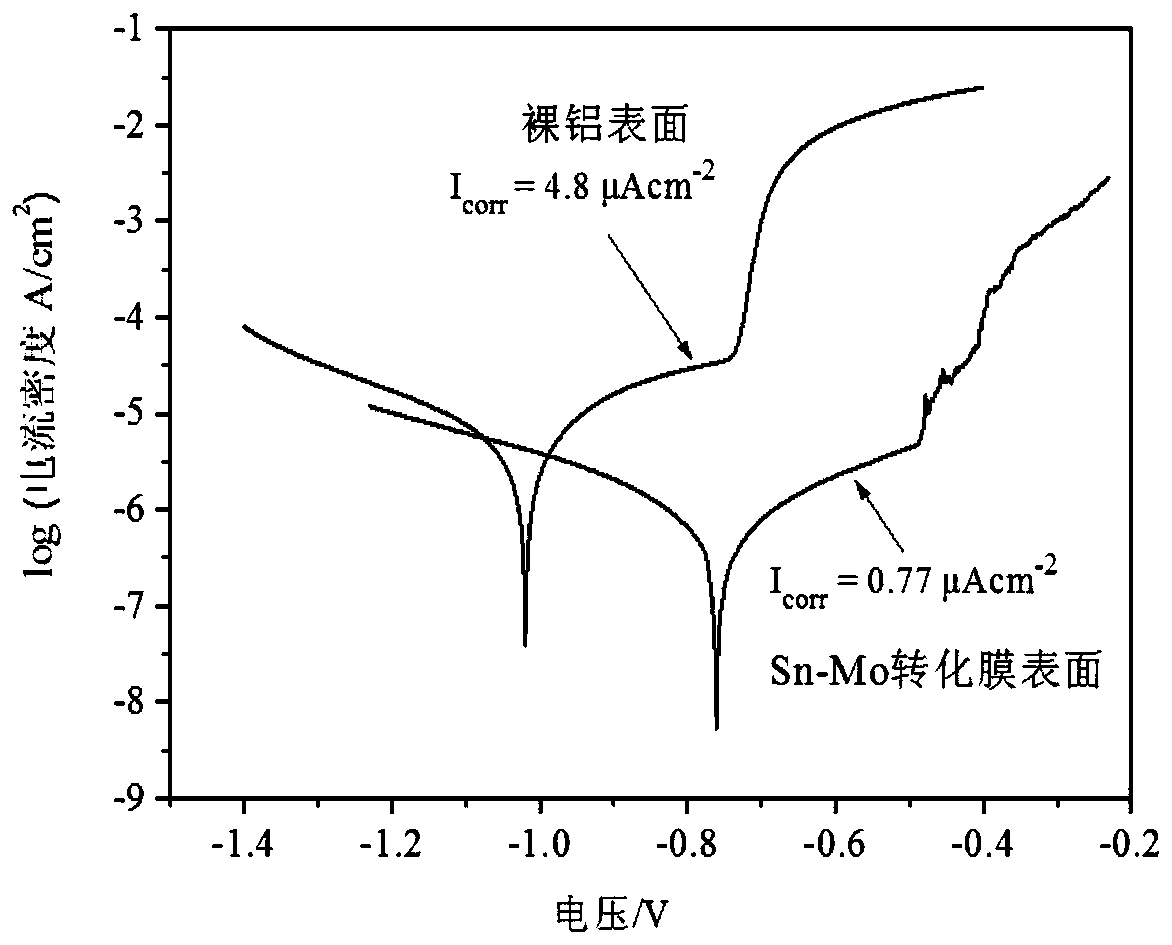

Image

Examples

Embodiment 1

[0033] (1) Preparation of a kind of aluminum alloy Sn-Mo alkaline conversion solution (taking 1 liter of solution as an example):

[0034] 1.5g of NaOH, 5.0g of NaOH 2 SnO 3 ·3H 2 O, 4.0 g Na 2 MoO 4 2H 2 O, and 3.0g of sodium citrate were added to 500ml of distilled water in turn (each raw material was completely dissolved before adding subsequent raw materials), dissolved and mixed; added distilled water 300ml, added solvent 3-methoxy-3-methyl-1- Butanol 15ml, stir evenly, add 1.0g potassium permanganate, stir to dissolve completely, add distilled water to 950ml, adjust pH value to 11.5, add water to 1000ml to obtain Sn-Mo alkaline chromium-free conversion liquid.

[0035] (2) an aluminum alloy alkaline conversion method, comprising the steps of:

[0036] (2-1) Substrate preparation: Cut the aluminum alloy (taking 6063 aluminum alloy as an example, it should be pointed out that the aluminum alloy described in the present invention includes but not limited to 6063 alumi...

Embodiment 2

[0041] (1) Preparation of a kind of aluminum alloy Sn-Mo alkaline conversion solution (taking 1 liter of solution as an example):

[0042] 2.2g of KOH, 9.0g of Na 2 SnO 3 ·3H 2 O, 8.0 g Na 2 MoO 4 2H 2 O, and 5.5g of potassium citrate were added to 500ml of distilled water in turn (each raw material was completely dissolved before adding subsequent raw materials), dissolved and mixed; add 300ml of distilled water, add solvent cyclohexanol 12ml, stir evenly, then add permanganese in turn Potassium chloride 0.5g, sodium hypochlorite 0.3g, add distilled water to 950ml, adjust the pH value to 12, add water to 1000ml to obtain the Sn-Mo alkaline chromium-free conversion solution.

[0043] (2) an aluminum alloy alkaline conversion method, comprising the steps of:

[0044] (2-1) base material preparation: same as embodiment 1

[0045] (2-2) Alkaline cleaning: Use a cleaning solution to carry out alkaline degreasing and decontamination cleaning of the polished aluminum alloy at...

Embodiment 3

[0049] (1) Preparation of a kind of aluminum alloy Sn-Mo alkaline conversion solution (taking 1 liter of solution as an example):

[0050] 1.8g of LiOH, 15.0g of Na 2 SnO 3 ·3H 2 O, 2.0 g Na 2 MoO 4 2H 2 O, and 8.0 g of sodium citrate were added to 500 ml of distilled water in turn (each raw material was completely dissolved before adding subsequent raw materials), dissolved and mixed; added distilled water 300 ml, added solvent 3-methoxy-3-methyl-1- 6ml each of butanol and cyclohexanol, stir evenly, then add 0.3g of potassium permanganate, 0.5g of sodium hypochlorite in turn, add distilled water to 950ml, adjust the pH value to 12.5, replenish water to 1000ml, and obtain Sn-Mo alkaline chromium-free Transformation solution.

[0051] (2) A kind of aluminum alloy alkaline conversion method comprises the steps:

[0052] (2-1) base material preparation: same as embodiment 1

[0053] (2-2) Alkaline cleaning: Use a cleaning solution to carry out alkaline degreasing and deco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com