Pressure-resistant and tensile PE pipe and production method thereof

A production method and pipe technology, which are applied in metal material coating process, coating, hot dip plating process, etc., can solve the problems of difficulty in meeting use requirements, decreased durability, poor pressure resistance, etc., and avoid intermolecular relaxation effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

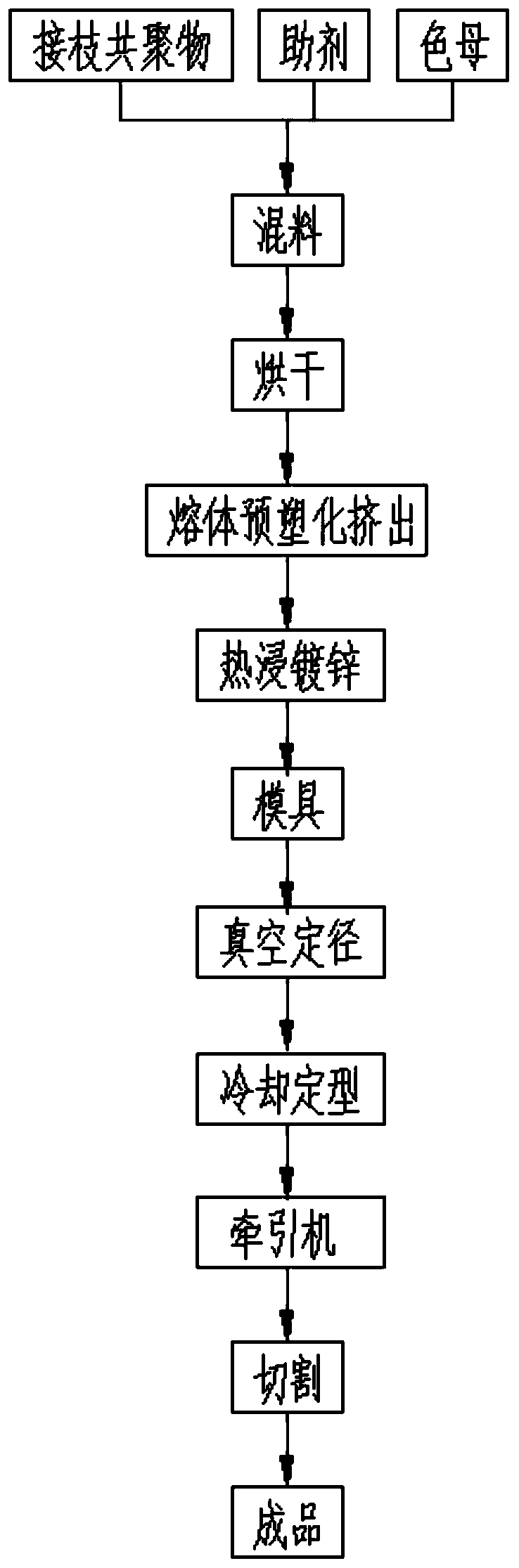

Image

Examples

Embodiment 1

[0020] A pressure-resistant and tensile-resistant PE pipe production method, the method is as follows:

[0021] (1) Nitrogen protection is passed into the reaction kettle, and 62 parts of high-density polyethylene, 13 parts of monomer and 5 parts of initiator are successively dropped in by mass parts, and the number-average molecular weight of the high-density polyethylene is 10 to 20 10,000, carry out copolymerization reaction;

[0022] During the copolymerization process, first raise the temperature to 75°C at 10°C / min, then raise the temperature to 190°C at 30°C / min, keep the temperature for 3 hours, then cool down to 45°C at 20°C / min, and the stirring rate is 90r / min;

[0023] The monomer is 4-isopropylphenylacetic acid and 1,4-diacetoxybutane in a mass ratio of 2:3, and the initiator is dicumyl peroxide and dibenzoyl peroxide by mass Mix ratio 2:1;

[0024] Then wash and filter with acetone, place the filter cake in an acetone solution for reflux extraction for 2 hours,...

Embodiment 2

[0029] A pressure-resistant and tensile-resistant PE pipe production method, the method is as follows:

[0030] (1) Nitrogen protection is passed into the reaction kettle, and 55 parts of high-density polyethylene, 9 parts of monomer and 6 parts of initiator are successively dropped in by mass parts, and the number-average molecular weight of the high-density polyethylene is 10 to 20 10,000, carry out copolymerization reaction;

[0031] During the copolymerization process, first raise the temperature to 80°C at 10°C / min, then raise the temperature to 195°C at 30°C / min, keep it warm for 3-4 hours, then lower the temperature to 40°C at 20°C / min, and the stirring rate is 1100r / min;

[0032] The monomer is mixed in ethyl methacrylate and 1,4-diacetoxybutane in a mass ratio of 5:3, and the initiator is dibenzoyl peroxide;

[0033] Then wash and filter with acetone, place the filter cake in an acetone solution for reflux extraction for 2 hours, and dry to obtain a graft copolymer; ...

Embodiment 3

[0038] A pressure-resistant and tensile-resistant PE pipe production method, the method is as follows:

[0039] (1) Nitrogen protection is passed into the reaction kettle, and 62 parts of high-density polyethylene, 13 parts of monomer and 5 parts of initiator are successively dropped in by mass parts, and the number-average molecular weight of the high-density polyethylene is 10 to 20 10,000, carry out copolymerization reaction;

[0040] During the copolymerization process, first raise the temperature to 80°C at 10°C / min, then raise the temperature to 180°C at 30°C / min, keep it warm for 4 hours, then lower the temperature to 52°C at 20°C / min, and the stirring rate is 110r / min;

[0041] The monomer is formed by mixing ethyl methacrylate, 4-isopropylphenylacetic acid, isopropyl methacrylate and 1,4-diacetoxybutane in a mass ratio of 1:1:3:2, Described initiator is dicumyl peroxide;

[0042] Then wash and filter with acetone, place the filter cake in an acetone solution for ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com