Black biological activated ceramic powder and application thereof

A technology of bioactive ceramics and bioceramics, used in prostheses, drug combinations, medical preparations containing active ingredients, etc., can solve the problems of non-degradable nanomaterials, difficult self-healing of the body, tissue defects, etc., and achieve good biological safety. , the effect of increasing the absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Preparation of black bioactive ceramic composite membranes. The black bioactive ceramic powder, binder, and solvent are mixed as raw materials, and after vacuum filtration and drying, a black bioactive ceramic composite membrane material is obtained. The binder can be biopolymer materials such as chitosan (CTS), gelatin, sodium alginate, chitin, hyaluronic acid, collagen, polyvinyl alcohol, polyethylene glycol, and polylactic acid. Wherein, the mass ratio of the black bioactive ceramic powder to the binder may be 1:(0.1-2). The solvent can be an acidic solution such as acetic acid, hydrochloric acid, phosphoric acid, nitric acid, etc.

[0061] As a preparation example of a black bioactive ceramic composite membrane, it includes: dispersing the black bioactive ceramic powder in an acidic solution of chitosan, and controlling the mass ratio of the black bioactive ceramic powder to chitosan to be 1:0.1- 2. After stirring evenly, carry out vacuum filtration. Wherein, the...

Embodiment 1

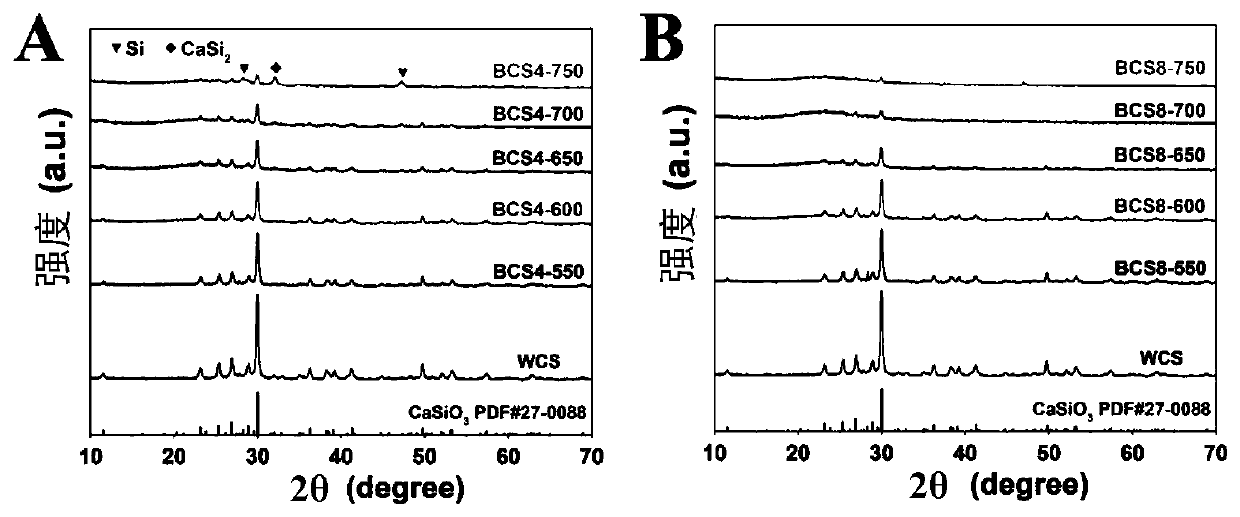

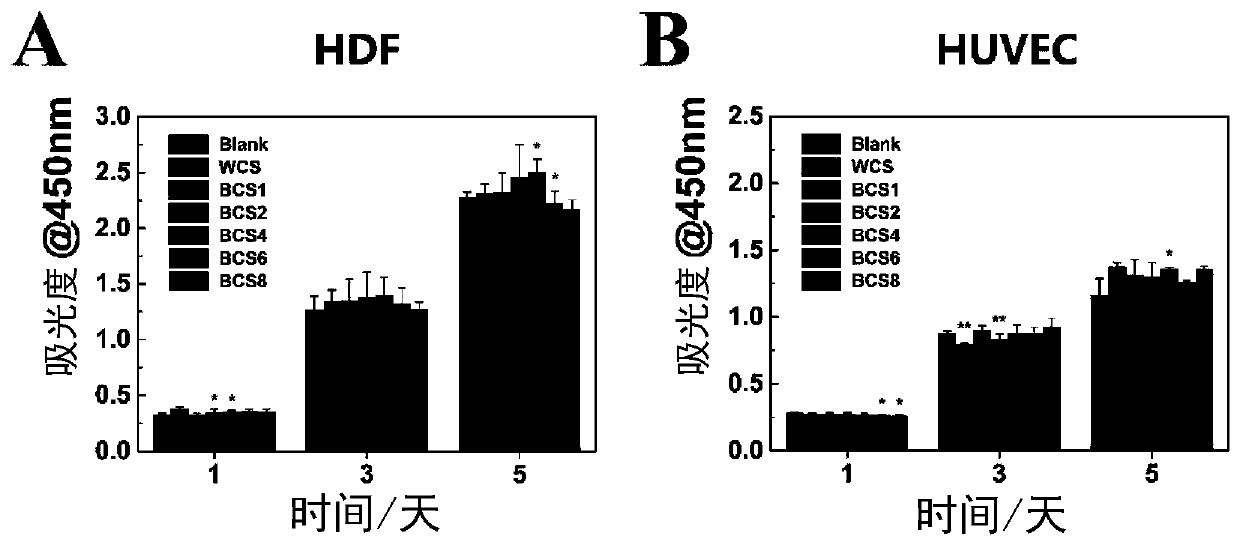

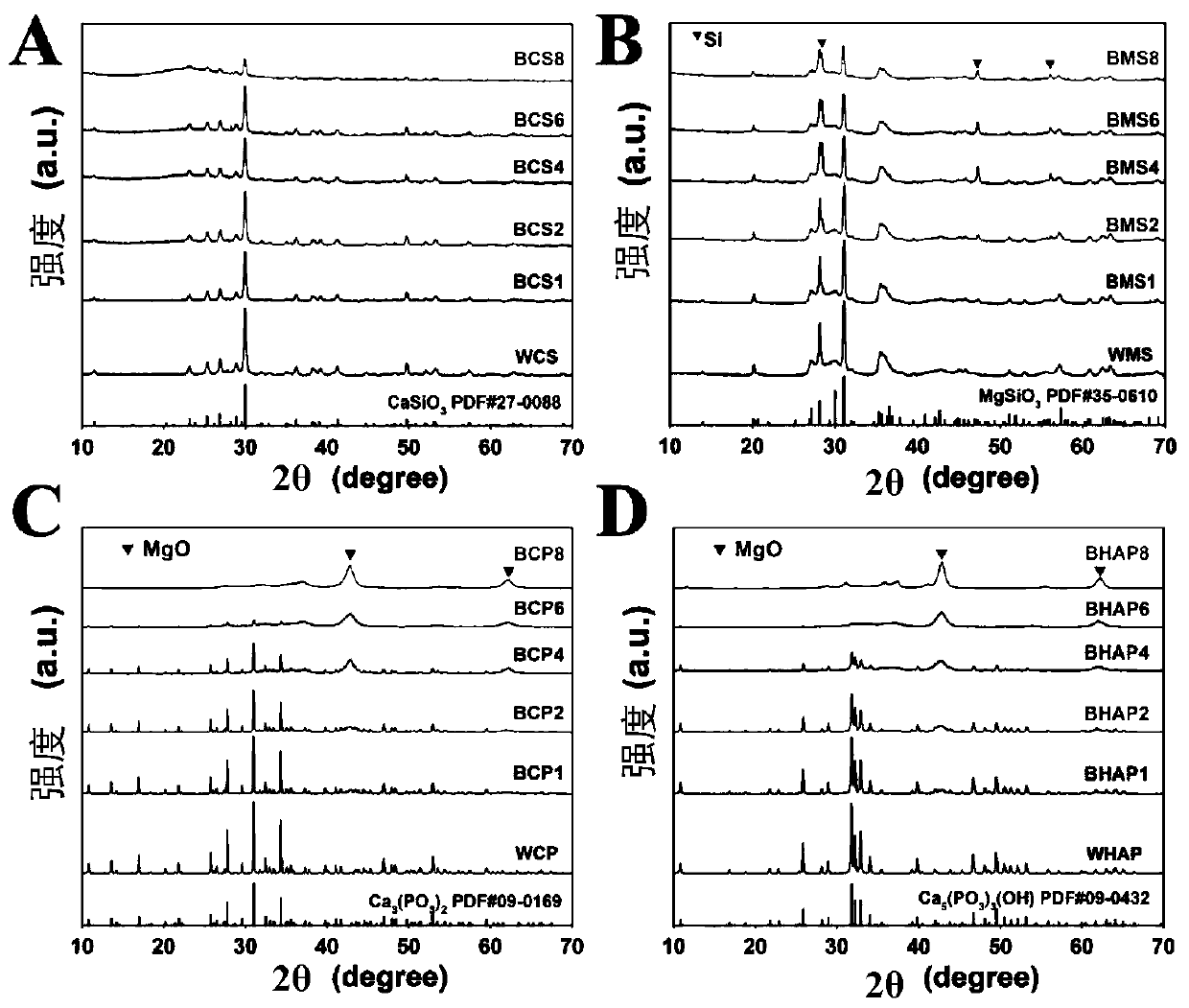

[0082] Take 1g white CaSiO 3 The ceramic powder (WCS) is mixed with Mg powder (0.1g, 0.4g, 0.6g, 0.8g) of different qualities, and then introduced into the alumina crucible boat;

[0083] Place the crucible boat in an argon atmosphere furnace, and raise the temperature at 2°C / min to a certain temperature (550°C, 600°C, 650°C, 700°C, or 750°C), and keep it warm for 4 hours. Naturally cool to room temperature, pickling and vacuum drying to obtain black calcium silicate ceramic powder. Among them, the black calcium silicate ceramic powder obtained by reaction at 650°C can be respectively recorded as BCS1, BCS4, BCS6, BCS8 powder;

[0084] 250mg chitosan powder was dissolved in 50mL acetic acid solution to obtain acidic CTS solution (5wt.%);

[0085] Weigh 250mg BCS4 powder and disperse in 10mL H 2 (3) mix 50mL of CTS solution with 10mL of BCS suspension, keep stirring, and add 2mL of ammonia water dropwise to obtain BCS-CTS suspension;

[0086] Draw 6mL of BCS-CTS suspension,...

Embodiment 2

[0093] Take 1g white CaSiO 3 Ceramic powder (WCS) and Mg powder (0.2g) are mixed evenly, then introduced into the alumina crucible boat;

[0094] Place the crucible boat in an argon atmosphere furnace, raise the temperature at 2°C / min to a certain temperature (550°C, 600°C, 650°C, 700°C, or 750°C), and keep it warm for 4 hours. Cool naturally to room temperature, then pickle and vacuum dry to obtain black calcium silicate ceramic powder;

[0095] The black calcium silicate ceramic powder obtained by reacting 0.2g Mg powder at 650°C is denoted as BCS2 powder;

[0096] 250mg chitosan powder was dissolved in 50mL acetic acid solution to obtain acidic CTS solution (5wt.%);

[0097] Weigh 250mg BCS2 powder and disperse in 10mL H 2 (3) mix 50mL of CTS solution with 10mL of BCS suspension, keep stirring, and add 2mL of ammonia water dropwise to obtain BCS-CTS suspension;

[0098] Draw 6mL of BCS-CTS suspension, select filter paper with a diameter of 5cm, and vacuum filter for 2mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com