A kind of rubber modified asphalt mixture and its preparation method and pavement structure

A technology for modification of asphalt mixture and rubber, which is applied in the field of pavement construction, can solve the problems of threshing and falling, and achieve the effects of improving the bonding state, enhancing flexibility, and improving deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

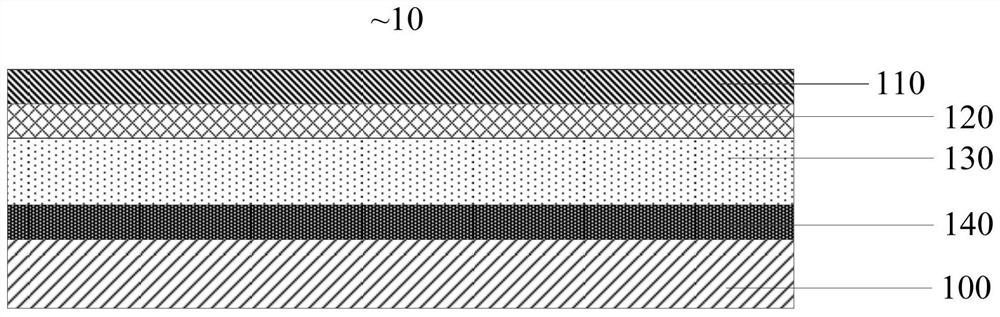

Image

Examples

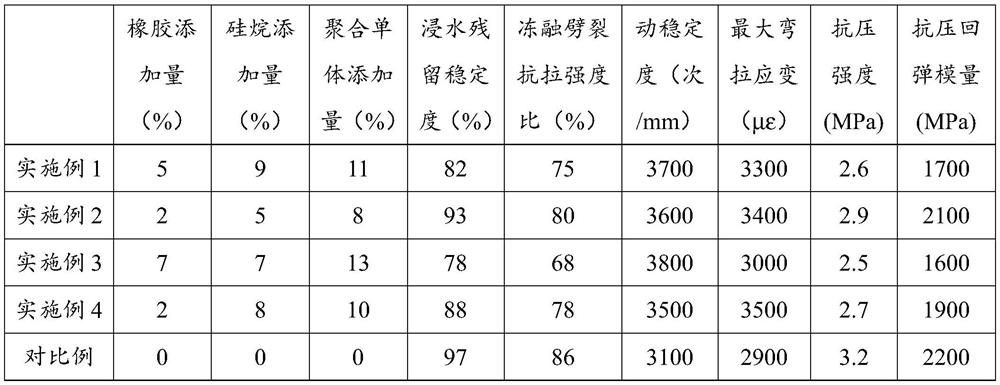

Embodiment 1

[0051] An asphalt mixture comprises 4 parts of asphalt, 71 parts of stone material, 5 parts of rubber particles, 9 parts of silane coupling agent and 11 parts of polymerized monomer, and the stone material is silicate stone material.

[0052] The polymerized monomer is 1-bromostyrene propylene, the silane coupling agent is vinyltrimethoxysilane, the asphalt is SBR modified asphalt, and the particle size of the rubber particles is 20 mesh.

[0053] The preparation method is as follows:

[0054] 1) Mix SBR modified asphalt with stone;

[0055] 2) Add a silane coupling agent to the above stirring mixture, and react at 100°C for 1.5h to obtain the first reaction mixture;

[0056] 3) adding the rubber particles into the first reaction mixture, stirring and mixing to obtain a second mixture;

[0057] 4) Add the mixed liquid of the polymerized monomer and the initiator to the second mixture, and carry out a polymerization reaction for 1.5 h under the condition of stirring at 110° C...

Embodiment 2

[0059] An asphalt mixture comprises 3 parts of asphalt, 82 parts of stone material, 2 parts of rubber particles, 5 parts of silane coupling agent and 8 parts of polymerized monomer, and the stone material is silicate stone material.

[0060] The polymerized monomer is 2-pentene, the silane coupling agent is γ-aminopropyltriethoxysilane, the asphalt is SBR modified asphalt, and the particle size of the rubber particles is 20 mesh.

[0061] The preparation method is as follows:

[0062] 1) Mix SBR modified asphalt with stone;

[0063] 2) adding a silane coupling agent to the above stirring mixture, and reacting at 80° C. for 1 hour to obtain the first reaction mixture;

[0064] 3) adding the rubber particles into the first reaction mixture, stirring and mixing to obtain a second mixture;

[0065] 4) Add the mixed liquid of the polymerization monomer and the initiator to the second mixture, and carry out the polymerization reaction for 15 minutes under the condition of stirring...

Embodiment 3

[0067] An asphalt mixture comprises 5 parts of asphalt, 68 parts of stone material, 7 parts of rubber particles, 7 parts of silane coupling agent and 13 parts of polymerized monomer, and the stone material is silicate stone material.

[0068] The polymerized monomer is ethyl styrene, the silane coupling agent is vinyltriacetoxysilane, the asphalt is SBR modified asphalt, and the particle size of the rubber particles is 20 mesh.

[0069] The preparation method is as follows:

[0070] 1) Mix SBR modified asphalt with stone;

[0071] 2) adding a silane coupling agent to the above stirring mixture, and reacting at 120° C. for 2 hours to obtain the first reaction mixture;

[0072] 3) adding the rubber particles into the first reaction mixture, stirring and mixing to obtain a second mixture;

[0073] 4) Adding the mixed solution of polymerized monomers and initiators to the second mixture, and polymerizing for 3 hours under the condition of stirring at 150° C. to obtain the rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com