Platinum-palladium-nickel chamfered-octahedron porous nano-cage electrocatalyst and preparation method therefor

An electrocatalyst, octahedral technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of mesoporous metal irregularity, metal nanocrystals are rarely reported, etc. Simple method, excellent activity and stability, high product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of platinum palladium nickel truncated octahedron porous nano cage electrocatalyst, described method comprises the steps:

[0035] 1) 50 mg of F127 and 1.5 mL of 20 mM potassium chloroplatinate, 1.5 mL of 20 mM sodium chloropalladate, 1.5 mL of 20 mM nickel chloride, and 0.2 mL of 6 M hydrochloric acid were placed under ultrasonic conditions. Mix evenly under high temperature, then add 2mL of ascorbic acid solution with a concentration of 0.1M, and let the mixed solution stand in an oil bath at 95°C for 4 hours. The final product is washed three times by centrifugation with water and ethanol, and dried at room temperature for later use;

[0036] 2) Redisperse the dried product in the previous step into an excess of concentrated nitric acid solution, stir at room temperature for three days, wash, centrifuge, and dry after the reaction to obtain a platinum-palladium-nickel truncated octahedral porous nanocage electrocatalyst.

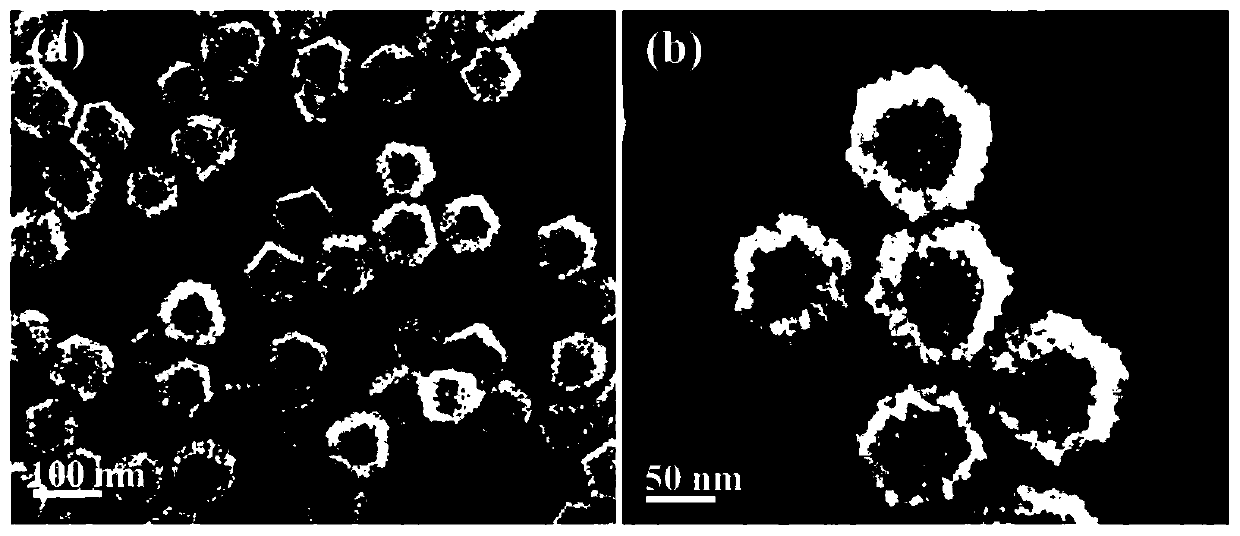

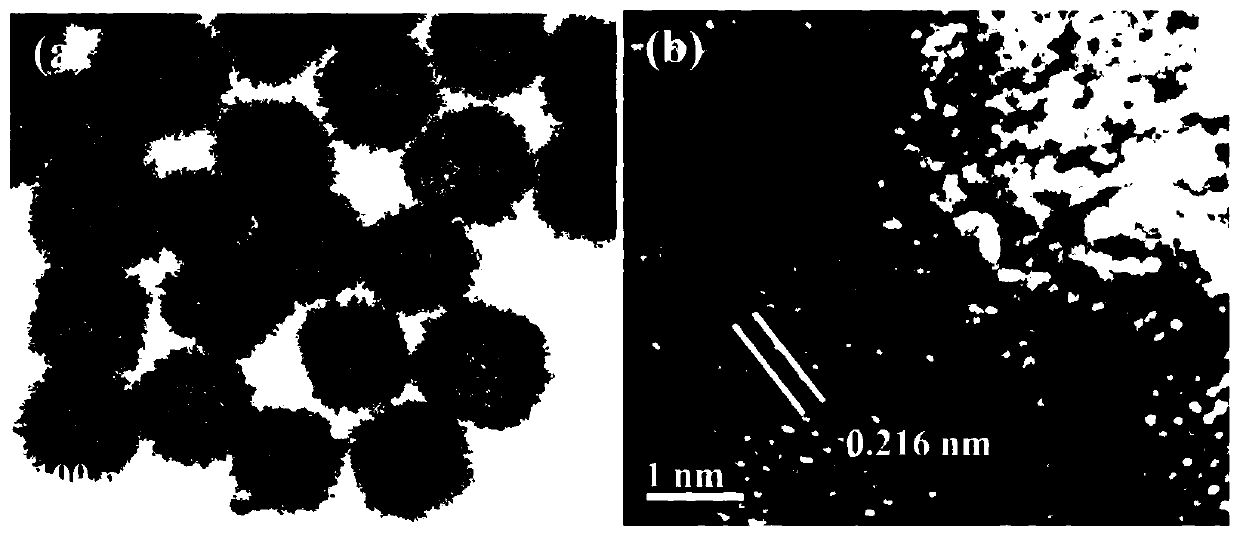

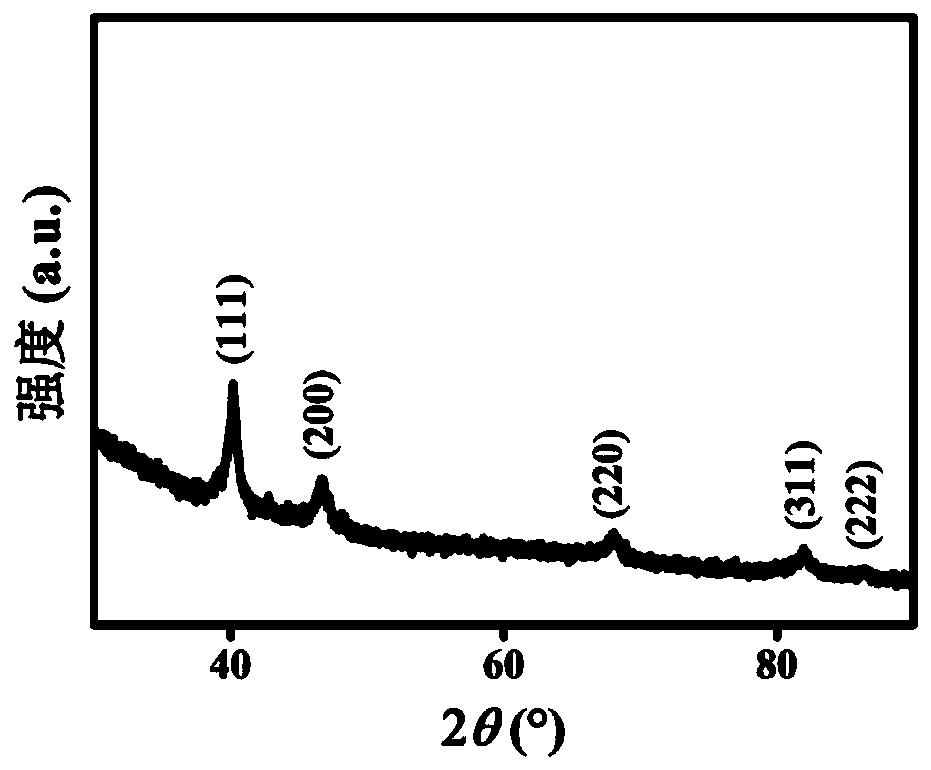

[0037] The SEM ...

Embodiment 2

[0040] A kind of preparation method of platinum-palladium-nickel octahedral porous nano-cage oxygen reduction catalyst, described method comprises the steps:

[0041] 1) 50mg of F127 and 0.6mL of 20mM potassium chloroplatinate, 0.6mL of 20mM sodium chloropalladate, 3.3mL of 20mM nickel chloride, 0.2mL of 6M hydrochloric acid under ultrasonic conditions Mix evenly under high temperature, then add 2mL of ascorbic acid solution with a concentration of 0.1M, and let the mixed solution stand in an oil bath at 95°C for 4 hours. The final product is washed three times by centrifugation with water and ethanol, and dried at room temperature for later use;

[0042] 2) redisperse the dried product in the previous step into an excess of concentrated nitric acid solution, stir at room temperature for three days, wash, centrifuge, and dry after the reaction to obtain a porous platinum-palladium-nickel octahedral nanocage electrocatalyst.

[0043] Obtain the SEM image of the platinum-palladi...

Embodiment 3

[0046] A kind of preparation method of platinum palladium nickel truncated octahedron porous nano cage, described method comprises the following steps:

[0047] 1) 50 mg of PVP and 1.5 mL of 20 mM potassium chloroplatinate, 1.5 mL of 20 mM sodium chloropalladate, 1.5 mL of 20 mM nickel chloride, and 0.2 mL of 6 M hydrochloric acid were placed under ultrasonic conditions. Mix evenly under the pressure, then add 2mL of ascorbic acid solution with a concentration of 0.1M, leave the mixed solution in an oil bath at 95°C for 2 hours, and wash the final product by centrifugation three times with water and ethanol.

[0048] 2) redisperse the dried product in the previous step into excess concentrated nitric acid solution, stir at room temperature for three days, wash, centrifuge and dry after the reaction to obtain a platinum-palladium-nickel truncated octahedral porous nanocage electrocatalyst.

[0049] Because in this synthesis process, the reaction time is not enough, can not obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com