Cubic aluminium nitride film, preparation method thereof and application

A technology of aluminum nitride and thin film, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problem that the controllability of process parameters is difficult to achieve, hinders the large-scale AlN thin film, and the cost of low-temperature deposition equipment is expensive issues such as low cost, strong stability and controllability, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Using aluminum chloride hydrate and urea as raw materials, set the molar ratio of urea / aluminum chloride to 6:1, weigh 1g (0.0041mol) of aluminum chloride hydrate and 1.49g (0.0249mol) of urea, and mix aluminum chloride (AlCl 3 ·6H 2 O, 99.99%) and urea (CO(NH 2 ) 2 , 99.5%) were respectively dissolved in 20ml of methanol solvent, after being completely dissolved, the urea solution was added to the aluminum chloride solution while stirring to obtain a clear and transparent stable precursor salt solution, and the constant temperature (80°C) was continuously stirred until the solution was 10ml to obtain the precursor salt concentrated solution, the aluminum ion concentration of which is 0.4142mol / L;

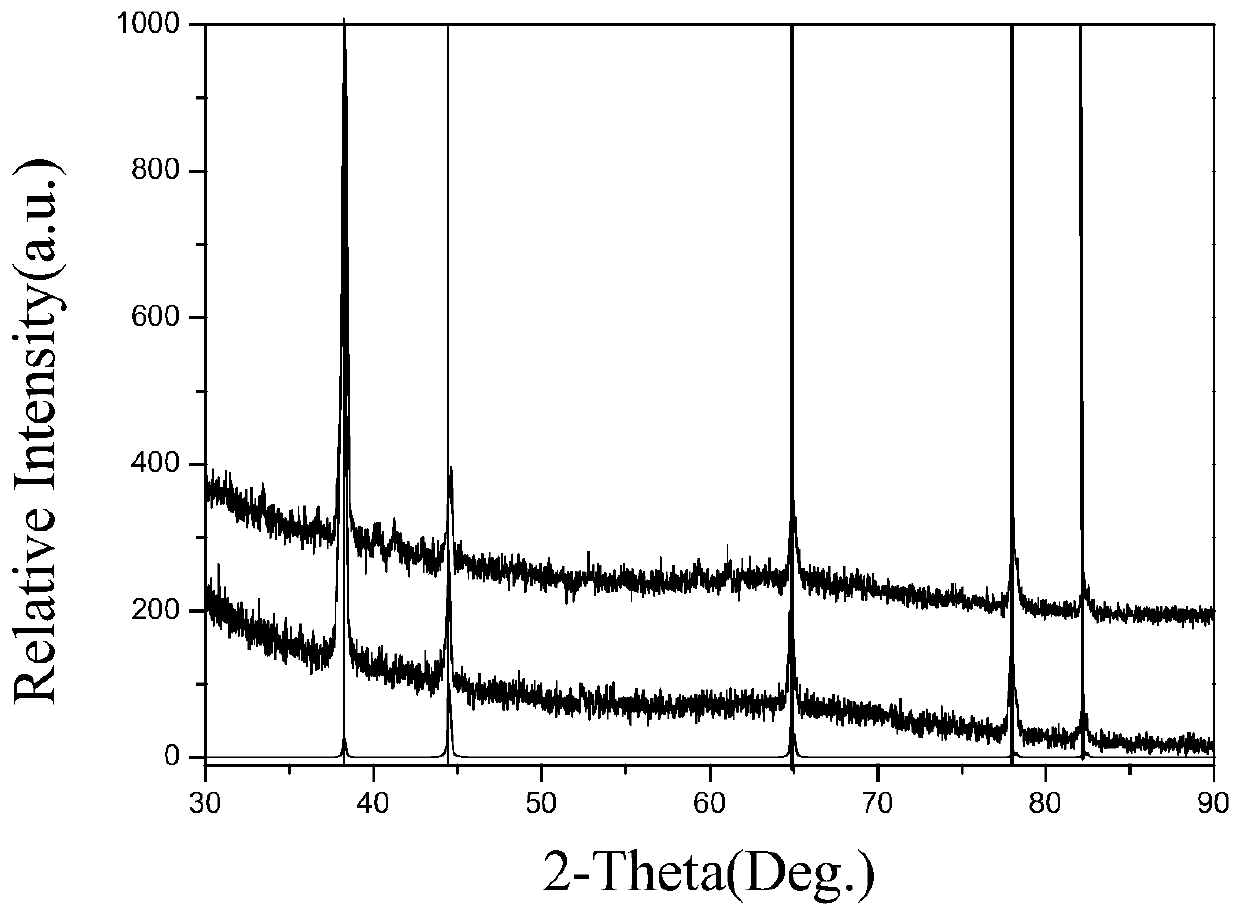

[0034] 2. Coat the concentrated solution of the precursor salt on the magnesium oxide single crystal substrate by spin coating, under the protection of nitrogen atmosphere (nitrogen flow rate: 0.4L / min), heat up to Calcination was carried out at 1000° C. and the holdi...

Embodiment 2

[0036] 1. Using aluminum chloride hydrate and urea as raw materials, set the molar ratio of dicyandiamide / aluminum chloride to 14:1, weigh 1g (0.0041mol) of aluminum chloride hydrate and 3.48g (0.0580mol) of urea, and mix the chlorine Aluminum (AlCl 3 ·6H 2 O, 99.99%) and urea (CO(NH 2 ) 2 , 99.5%) were respectively dissolved in 20ml of methanol solvent, after being completely dissolved, the urea solution was added to the aluminum chloride solution while stirring to obtain a clear and transparent stable precursor salt solution, and the constant temperature (80°C) was continuously stirred until the solution was 20ml, to obtain the precursor salt concentrated solution, its aluminum ion concentration is 0.2071mol / L;

[0037] 2. Coat the concentrated solution of the precursor salt on the alumina single crystal substrate by spin coating, under the protection of nitrogen atmosphere (nitrogen flow rate: 0.4L / min), raise the temperature in the alumina crucible at a heating rate of ...

Embodiment 3

[0039] 2.1. Using aluminum chloride hydrate and urea as raw materials, set the molar ratio of urea / aluminum chloride to 6:1, weigh 1g (0.0041mol) of aluminum chloride hydrate and 1.49g (0.0249mol) of urea, and mix the chlorine Aluminum (AlCl 3 ·6H 2 O, 99.99%) and urea (CO(NH 2 ) 2, 99.5%) were dissolved in 10ml of glycerol solvent respectively, after being completely dissolved, the urea solution was added to the aluminum chloride solution while stirring to obtain a clear and transparent stable precursor salt solution, and the constant temperature stirring (80°C) to The solution is 20ml, and the precursor salt concentrated solution is obtained, and its aluminum ion concentration is 0.2071mol / L;

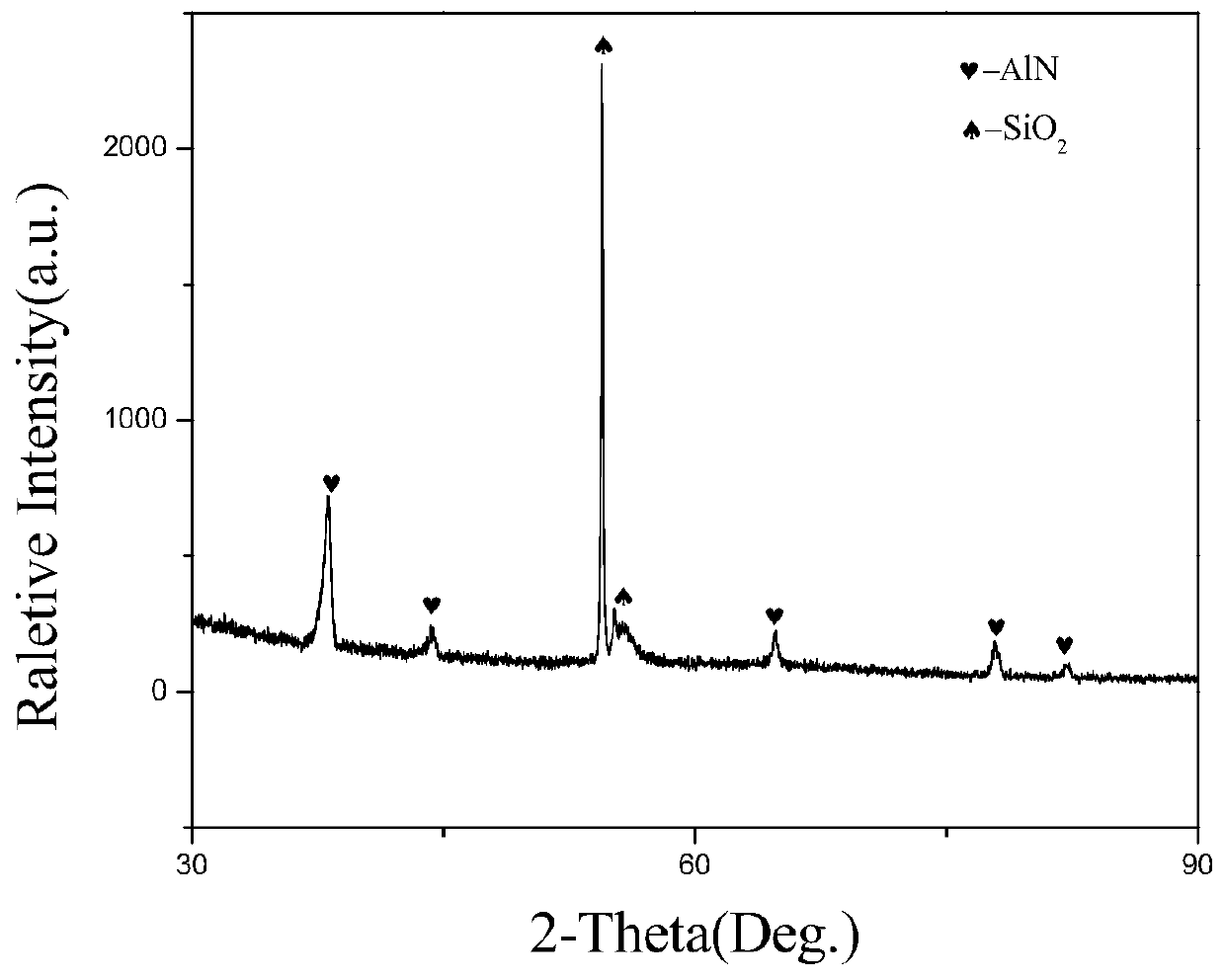

[0040] 2. Coat the concentrated solution of the precursor salt on the silicon single crystal substrate by spin coating, under the protection of a nitrogen atmosphere (nitrogen flow rate: 0.4L / min), raise the temperature in an alumina crucible at a rate of 3°C / min to 1000 ℃ for cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com