Transparent rigidity-and-toughness balanced thermoforming homo-polypropylene resin, and preparation method and application thereof

A homopolypropylene and thermoforming technology, which is applied in the field of polypropylene resin, can solve the problems that the improvement of polypropylene transparency is not ideal, the transparency improvement is not as good as that of sorbitol, and the thermoforming processing time is shortened to achieve the appearance. Good performance, short thermoforming cycle, low yellowness index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

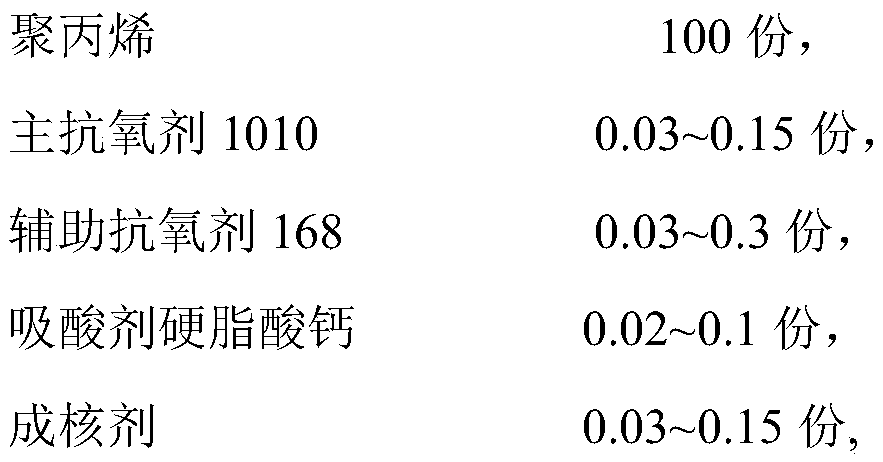

Method used

Image

Examples

Embodiment 1

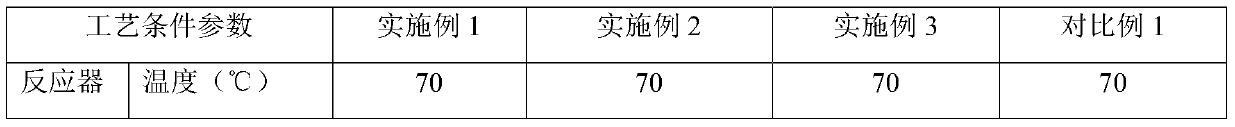

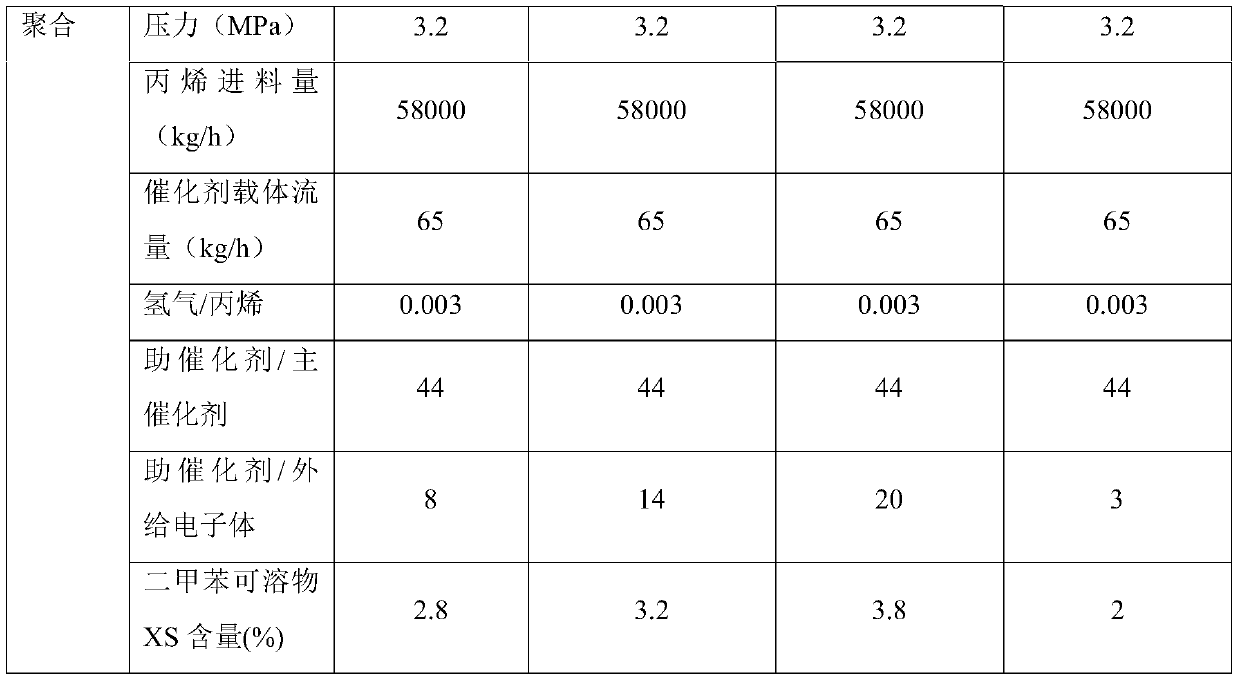

[0030] In Catalyst SHAC TM 201. In the presence of cocatalyst triethylaluminum and external electron donor n-propyltrimethoxysilane, add propylene and hydrogen to the fully mixed Unipol gas-phase fluidized reactor for polymerization reaction, and control the temperature of the reactor during the reaction 70°C, reaction pressure 3.2MPa, hydrogen addition 3kg / h, propylene / hydrogen ratio 0.003, catalyst support flow rate 65kg / h, propylene feed 58000kg / h, cocatalyst / external electron donor ratio 8 , the co-catalyst / primary catalyst ratio is 44. The advanced control system controls the feeding amount of each material to maintain a constant component ratio, and the flow rate is stable. Real-time fine-tuning of the catalyst and propylene feeding amount ensures that the partial pressure of propylene is improved. Reactor load to 52t / h to obtain polypropylene powder.

Embodiment 2

[0032] In Catalyst SHAC TM 201. In the presence of cocatalyst triethylaluminum and external electron donor n-propyltrimethoxysilane, add propylene and hydrogen to the fully mixed Unipol gas-phase fluidized reactor for polymerization reaction, and control the temperature of the reactor during the reaction 70°C, reaction pressure 3.2MPa, hydrogen addition 3kg / h, propylene / hydrogen ratio 0.003, catalyst carrier flow rate 65kg / h, propylene feed 58000kg / h, cocatalyst / external electron donor ratio 14 , the co-catalyst / primary catalyst ratio is 44. The advanced control system controls the feeding amount of each material to maintain a constant component ratio, and the flow rate is stable. Real-time fine-tuning of the catalyst and propylene feeding amount ensures that the partial pressure of propylene is improved. Reactor load to 52t / h to obtain polypropylene powder.

Embodiment 3

[0034] In Catalyst SHAC TM201. In the presence of cocatalyst triethylaluminum and external electron donor n-propyltrimethoxysilane, add propylene and hydrogen to the fully mixed Unipol gas-phase fluidized reactor for polymerization reaction, and control the temperature of the reactor during the reaction 70°C, reaction pressure 3.2MPa, hydrogen addition 3kg / h, propylene / hydrogen ratio 0.003, catalyst carrier flow rate 65kg / h, propylene feed 58000kg / h, cocatalyst / external electron donor ratio 20 , the co-catalyst / primary catalyst ratio is 44. The advanced control system controls the feeding amount of each material to maintain a constant component ratio, and the flow rate is stable. Real-time fine-tuning of the catalyst and propylene feeding amount ensures that the partial pressure of propylene is improved. Reactor load to 52t / h to obtain polypropylene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Top diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com