Preparation method of two-dimensional molybdenum carbide/graphene nanosheet composite material

A technology of graphene nanosheets and composite materials, which is applied in the field of preparation of two-dimensional molybdenum carbide/graphene nanosheet composite materials, achieving the effects of easy control of process parameters, convenient operation, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 1.23g of ammonium molybdate and add it into 40mL of distilled water, fully dissolve to form a uniform aqueous solution.

[0026] Dissolve 1.3 g of cetyltrimethylammonium bromide (CTAB) in 10 mL of ethanol, add 5 mL of 4.2 g / L graphene oxide ethanol dispersion, and ultrasonically disperse for 30 min to form an ethanol dispersion.

[0027] Pour the above ethanol dispersion into the aqueous solution, stir well for 0.5h, transfer to the reaction kettle, seal it, heat to 120°C for hydrothermal reaction for 12h, take out the product, wash with distilled water, and centrifugally dry, repeat the treatment 1-2 times.

[0028] The washed and dried product was heated at 800° C. for 2 h in an air atmosphere to prepare a two-dimensional molybdenum carbide / graphene nanosheet composite material.

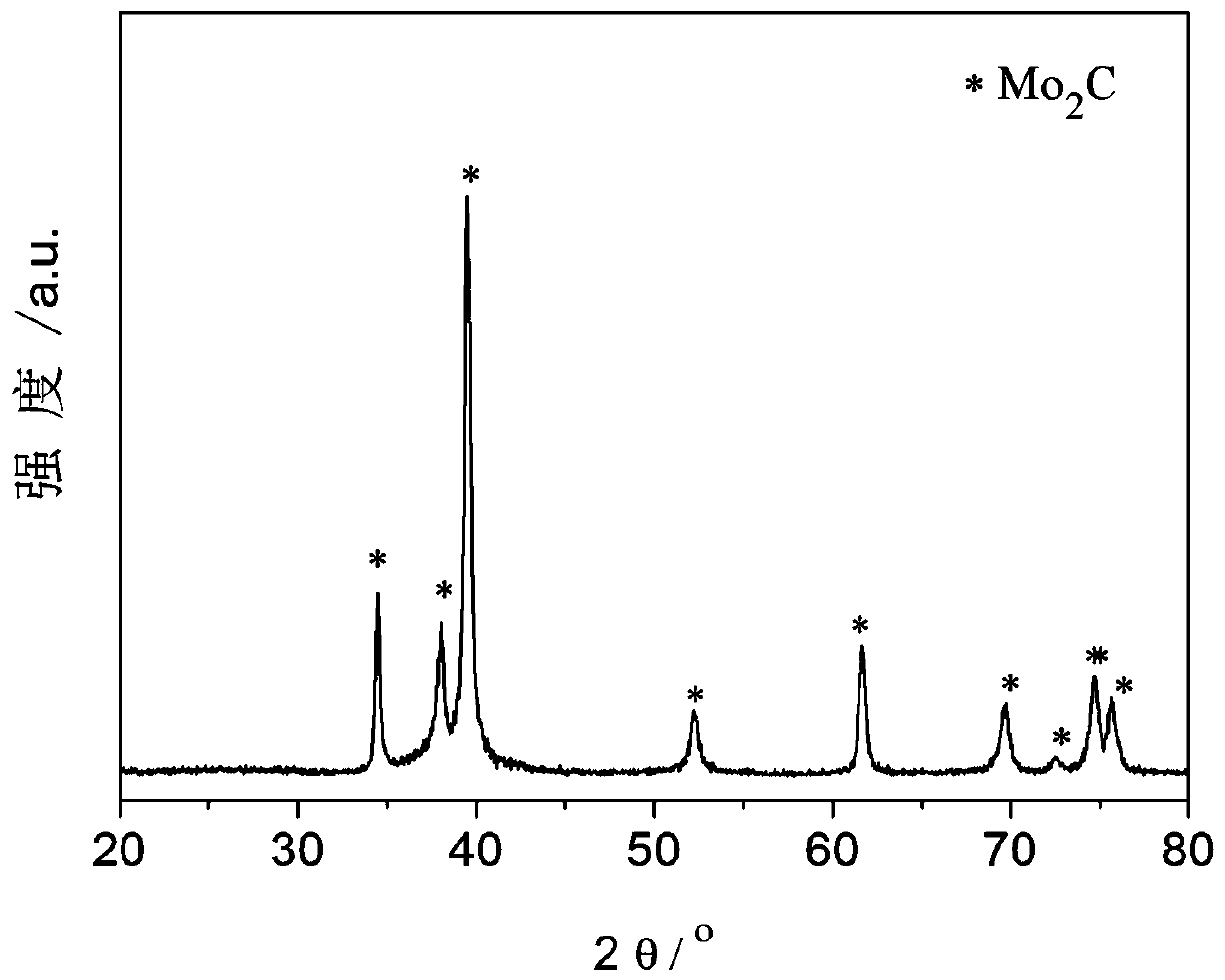

[0029] figure 1 The XRD pattern of the two-dimensional structured molybdenum carbide / graphene nanosheet composite prepared above is given. Comparing it with the standard spectrum of ...

Embodiment 2

[0033] Weigh 1.23g of ammonium molybdate and add it into 40mL of distilled water, fully dissolve to form a uniform aqueous solution.

[0034] Dissolve 0.2 g of cetyltrimethylammonium bromide (CTAB) in 15 mL of ethanol, add 21 mg of graphene oxide, and ultrasonically disperse for 30 min to obtain an ethanol dispersion.

[0035] Pour the above ethanol dispersion into the aqueous solution, stir well for 0.5h, transfer to the reaction kettle, seal it, heat to 120°C for hydrothermal reaction for 12h, take out the product, wash with distilled water, and centrifugally dry, repeat the treatment 1-2 times.

[0036] The washed and dried product was heated at 800° C. for 2 h in an air atmosphere to prepare a two-dimensional molybdenum carbide / graphene nanosheet composite material.

[0037] The composite material prepared above is used as the cathode material, coated on the surface of the electrode, and exhibits high electrocatalytic activity in the hydrogen evolution reaction of electrol...

Embodiment 3

[0039] Weigh 1.23g of ammonium molybdate and add it into 25mL of distilled water, fully dissolve to form a uniform aqueous solution.

[0040] Dissolve 1.0 g of cetyltrimethylammonium bromide (CTAB) in 10 mL of ethanol, add 5 mL of 4.2 g / L graphene oxide ethanol dispersion, and ultrasonically disperse for 30 min to obtain an ethanol dispersion.

[0041] Pour the above ethanol dispersion into the aqueous solution, stir well for 0.5h, transfer to the reaction kettle, seal it, heat to 120°C for hydrothermal reaction for 12h, take out the product, wash with distilled water, and centrifugally dry, repeat the treatment 1-2 times.

[0042] The washed and dried product was heated at 800° C. for 2 h in an air atmosphere to prepare a two-dimensional molybdenum carbide / graphene nanosheet composite material.

[0043] The composite material prepared above is used as the cathode material, coated on the surface of the electrode, and exhibits high electrocatalytic activity in the hydrogen evol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overpotential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com