Method for extracting soluble dietary fiber in soy sauce residues by supercritical CO2 system assisted enzyme-ultrasonic technique

An ultrasonic technology, dietary fiber technology, applied in separation methods, solid solvent extraction, food ultrasonic treatment, etc., can solve the problems of physical and chemical properties of soluble dietary fiber, doubts about product safety, and ineffective utilization of soy sauce residue fat and protein. , to achieve high-value utilization, reduce crude fiber content, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

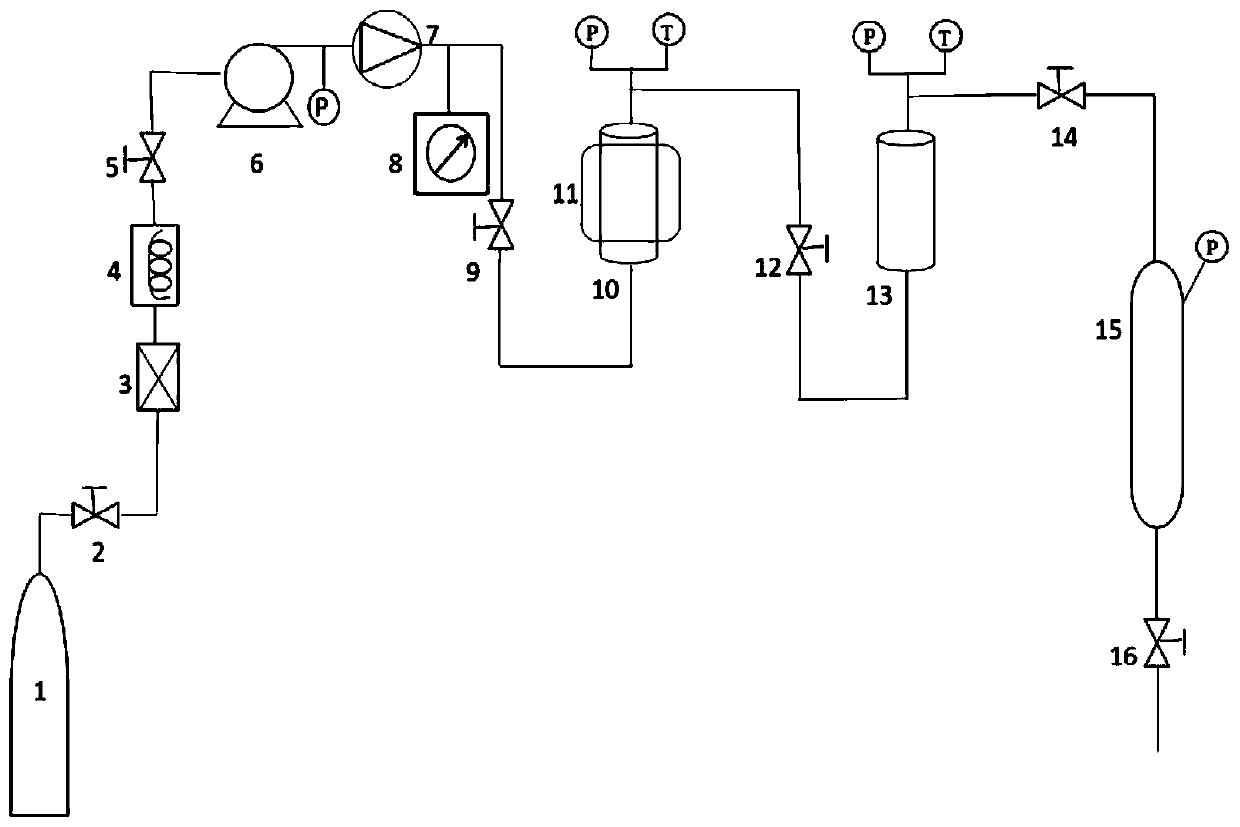

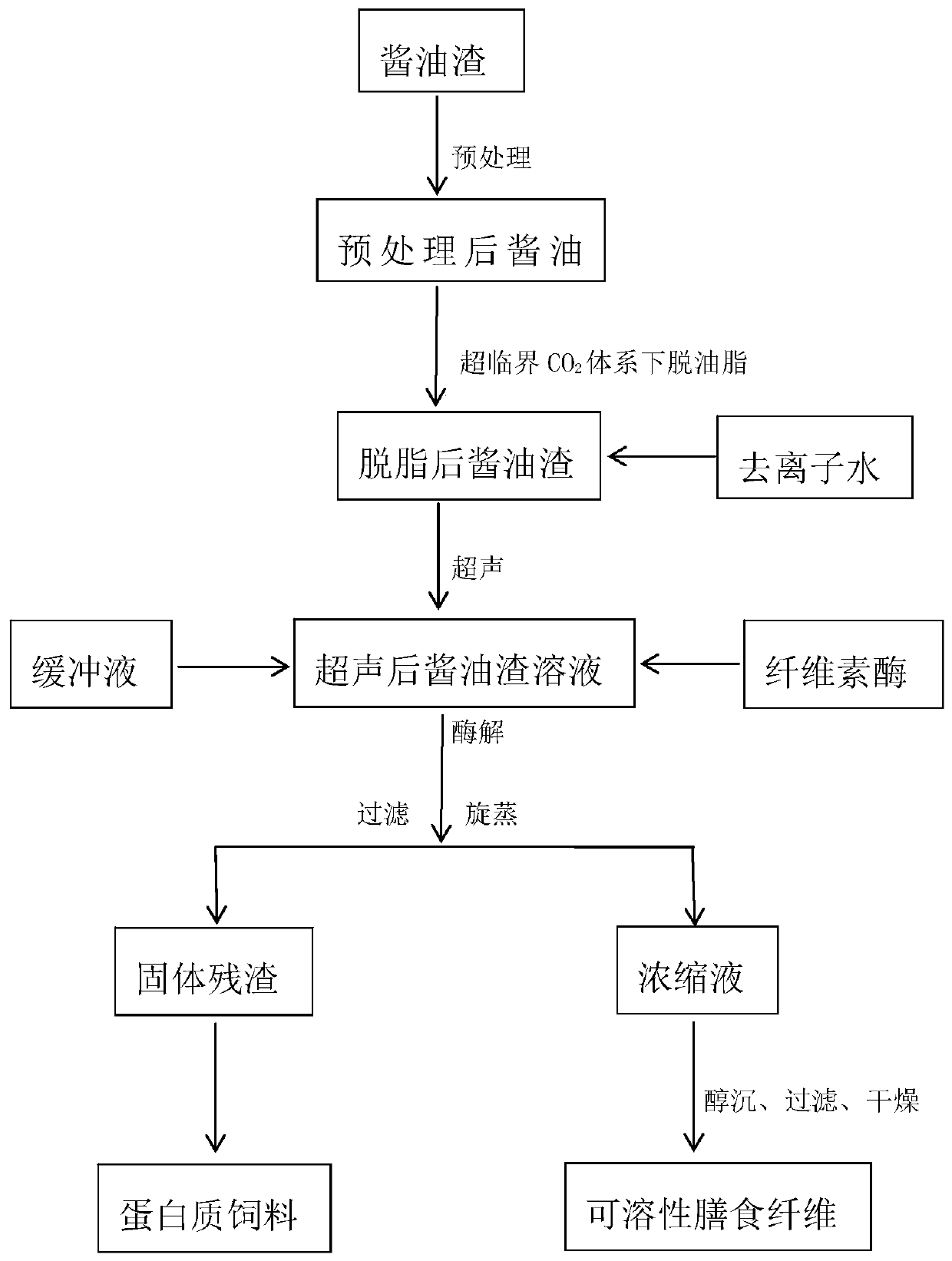

[0041] Add 268g of dry soy sauce residue to supercritical CO 2 In the reactor of the device, set the reaction temperature at 60°C, the pressure at 15MPa, and use CO 2 Replace the air in the device, turn on the high-pressure pump and heater to raise the temperature and pressure of the reaction to the set value. After reacting for 180min, turn off the heater and wait for the reactor to cool down to room temperature, then slowly remove the CO in the system 2 Recycle into the buffer tank, collect the extracted oil from the separation kettle, and take out the defatted soy sauce residue in the reaction kettle.

Embodiment 2-5

[0043] Accurately weigh a certain amount of degreased soy sauce residue, add ultrapure water according to the material-to-liquid ratio of 1:30, 1:35, 1:40, and 1:45, and use an ultrasonic cell pulverizer to ultrasonically treat the above four groups of soy sauce residue solutions , set the ultrasonic power to 400W, and the ultrasonic time to 5min. After the ultrasonic was finished, add 15.1ml of sodium acetate (1.0M) + 5.9ml of acetic acid (1.0M) buffer solution to the four groups of solutions, adjust the pH to 5.0, and then add 5 % cellulase, enzymolysis at 50°C for 30min. After the enzymolysis, the enzymolysis solution was suction-filtered, the filtrate was rotary evaporated to obtain a concentrated solution, 4 times the volume of absolute ethanol was added to precipitate for 10 hours, and the obtained precipitate was filtered and dried at 60°C for 4 hours to obtain soluble dietary fiber.

[0044] Example 2 3 4 5 Mass of soy sauce residue (g) 2.0450 2.01...

Embodiment 6-10

[0047] Accurately weigh a certain amount of degreased soy sauce residue, add ultrapure water according to the optimal material-to-liquid ratio of 1:35, and use an ultrasonic cell pulverizer to ultrasonically treat the above soy sauce residue solution, set the ultrasonic power to 400W, and the ultrasonic time to 1min and 3min respectively |, 5min, 6min, 7min, after the end of ultrasound, add 15.1ml of sodium acetate (1.0M) + 5.9ml of acetic acid (1.0M) buffer solution to the five groups of solutions, adjust the pH to 5.0, and then add 5% Cellulase, enzymatic hydrolysis at 50°C for 30min. After the enzymolysis, the enzymolysis solution was suction-filtered, the filtrate was rotary evaporated to obtain a concentrated solution, 4 times the volume of absolute ethanol was added to precipitate for 10 hours, and the obtained precipitate was filtered and dried at 60°C for 4 hours to obtain soluble dietary fiber.

[0048] Example 6 7 8 9 10 Mass of soy sauce residue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com