A waterproof and wear-resistant composite floor and its production method

A composite floor and production method technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of warpage, long production cycle and high production cost of composite floors, and achieve good waterproof performance and Wear resistance, not easy to delaminate or deform, the effect of shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

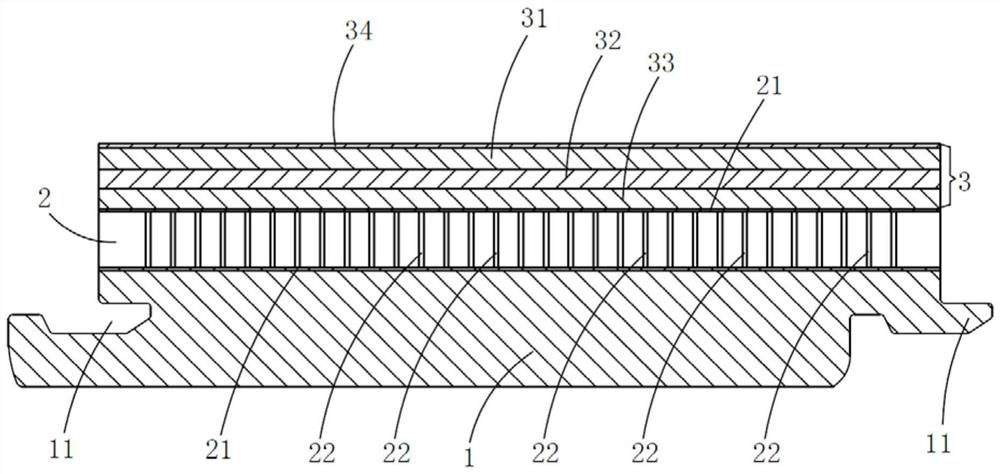

[0080] A production method of a waterproof and wear-resistant composite floor, figure 1 and 2 shown, including the following steps,

[0081] Making PVC composite layer prefabricated parts, including the following sub-steps,

[0082]a), the compounding sub-step of PVC composite layer embryo parts, transport the PVC wear-resistant layer 31, the PVC pattern layer 32 and the PVC plastic layer 33 to the hot pressing equipment for hot pressing and compounding, and the PVC wear-resistant layer 31 is superimposed on the PVC pattern On the top of the layer 32, the PVC pattern layer 32 is stacked on the top of the PVC plastic layer 33, and the PVC wear-resistant layer 31, the PVC pattern layer 32 and the PVC plastic layer 33 are hot-pressed and composited into an integrated composite sheet or Composite membrane material, so as to obtain PVC composite layer embryo products;

[0083] B), the corona sub-step of the PVC composite layer embryo product, the corona treatment of the PVC comp...

Embodiment 2

[0142] A waterproof and wear-resistant composite floor, figure 1 As shown, it includes a waterproof base material layer 1, a cushion layer 2, and a prefabricated PVC composite layer prefabricated part 3 compounded by a hot pressing process. The PVC composite layer prefabricated part 3 includes a PVC wear-resistant layer 31 from top to bottom. , PVC pattern layer 32 and PVC plastic layer 33.

[0143] The main structure of this embodiment is the same as that of Embodiment 1. figure 1 Shown is a schematic structural view of the first waterproof and wear-resistant composite floor produced according to the production method of the present invention.

[0144] Wherein, the PVC composite layer prefabricated part 3 is a sheet material or a film material, and the PVC plastic layer 33 is made of a PVC sheet material or a PVC film material. PVC composite layer prefab 3 is a prefabricated part with extremely thin thickness, very good waterproof performance and wear resistance, PVC compos...

Embodiment 3

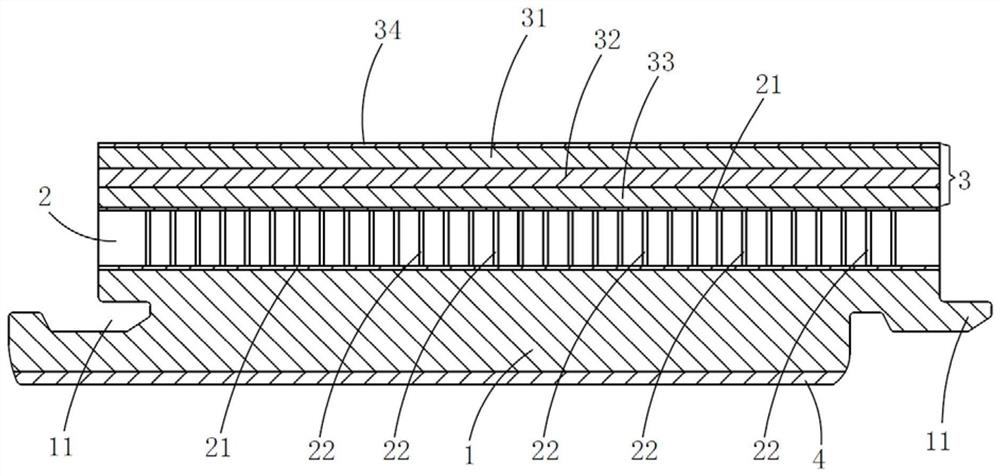

[0157] A waterproof and wear-resistant composite floor, figure 2 As shown, it includes a waterproof base material layer 1, a cushion layer 2, and a prefabricated PVC composite layer prefabricated part 3 compounded by a hot pressing process. The PVC composite layer prefabricated part 3 includes a PVC wear-resistant layer 31 from top to bottom. , PVC pattern layer 32 and PVC plastic layer 33.

[0158] The main structure of this embodiment is the same as that of Embodiment 1. figure 2 Shown is a structural schematic diagram of the second waterproof and wear-resistant composite floor produced according to the production method of the present invention.

[0159] The upper surface and the lower surface of the soft cushion layer 2 treated with surface corona are respectively densely covered with a shrinking hole at the outer end and interconnected micro-holes at the bottom. At the same time, the upper surface of the waterproof base material layer 1 is coated with a glue layer, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com