RFID tag of silver paste antenna process and chip packaging method

An RFID label and chip packaging technology, which is applied to record carriers, instruments, and computer parts used in machines. It can solve the problems of limited selection of label substrates, low packaging qualification rate, substrate deformation, etc., and improve packaging. Productivity and RFID tag throughput, parasitic resistance and capacitance suppression, cost and energy reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are only exemplary and are not intended to limit the scope of the present invention. In addition, in the following description, descriptions of well-known structures and technologies are omitted to avoid unnecessarily obscuring the concept of the present invention.

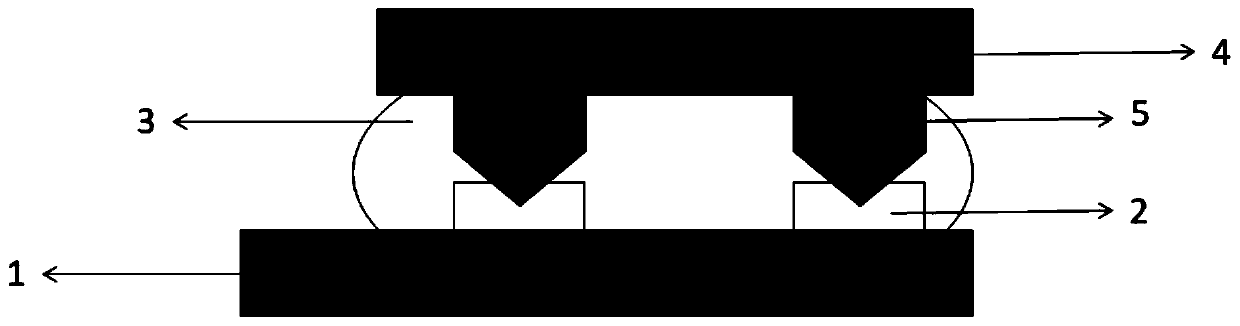

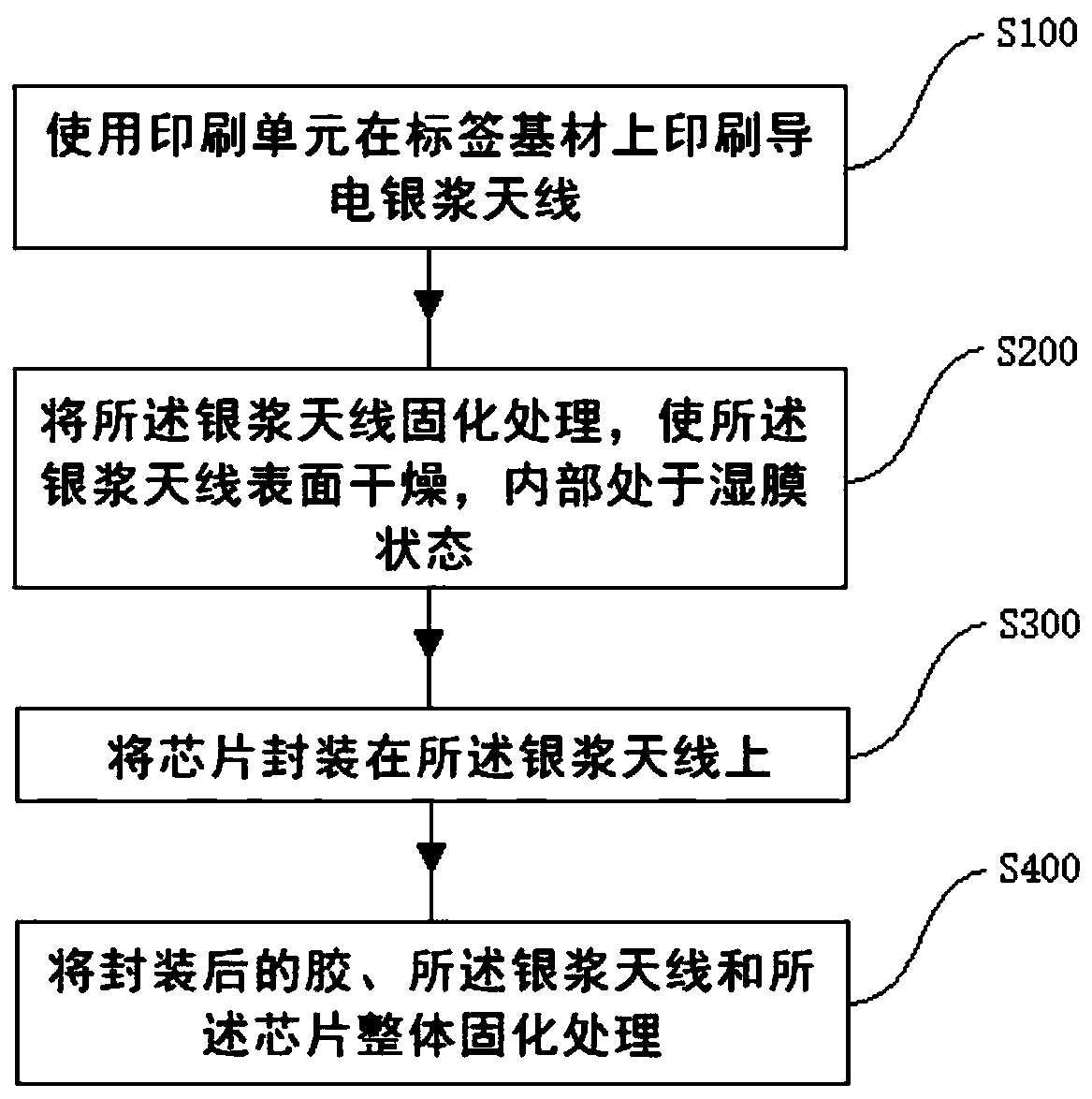

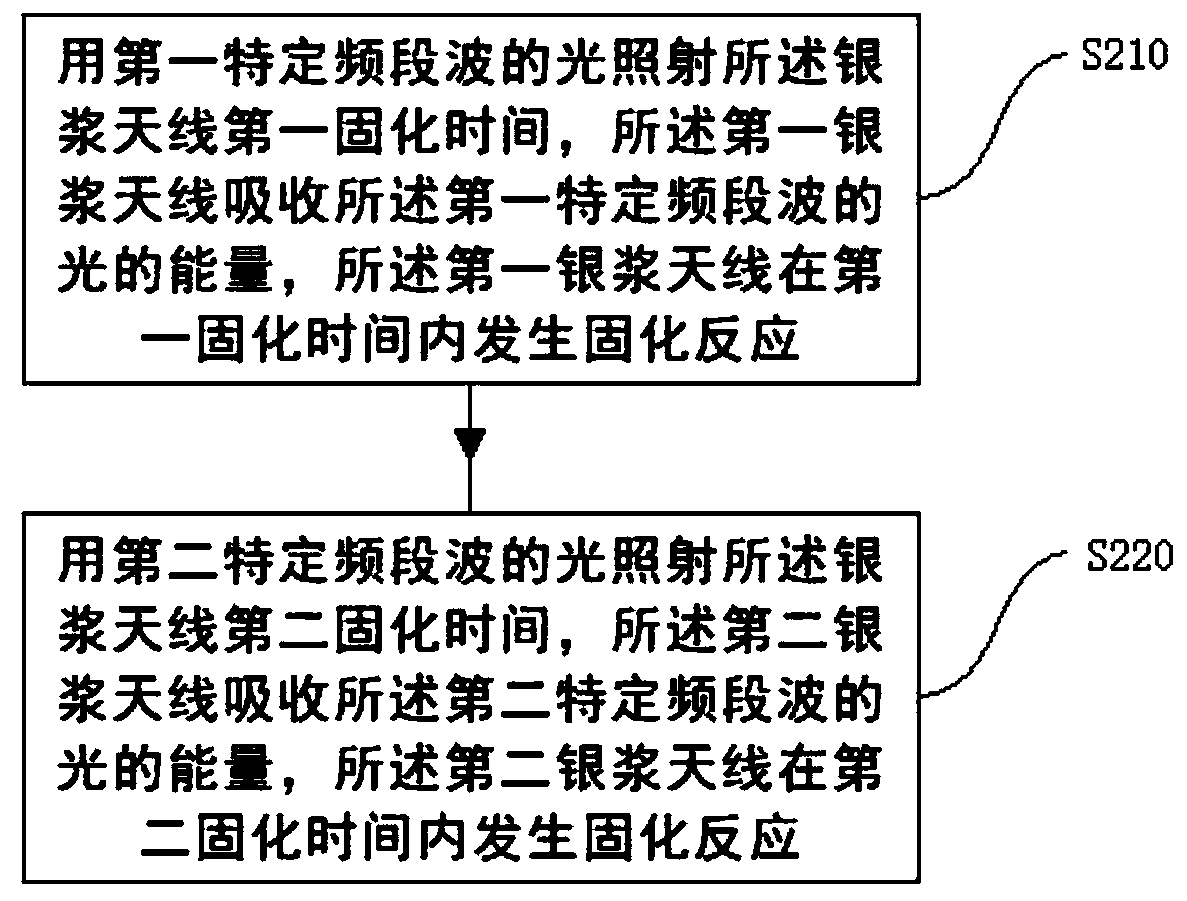

[0044] RFID tags use special conductive silver paste, and use a printer to print the silver paste antenna on the label substrate; the line automatically flows to the curing unit to dry the surface of the silver paste antenna; then enters the packaging equipment for the chip binding process; binding After the end, the line will automatically flow to the secondary overall curing unit for the overall drying and cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com