A kind of processing method of polyester fabric

A processing method and polyester technology, applied in the field of fabric processing, can solve the problems of high maintenance and maintenance costs, complicated production procedures, low production efficiency, etc., and achieve excellent color fastness to washing, color fastness to rubbing, hand feel and The effect of good washing fastness and low pressing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A processing method for polyester fabrics, including the following steps:

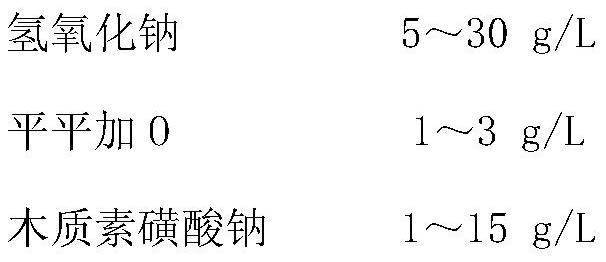

[0052] (1) Polyester fabric alkali reduction pretreatment: the use of polyester fabric, the first fabric alkali reduction pretreatment, alkali reduction pretreatment process, the addition of tea saponin and sodium lignosulfonate, in order to ensure a certain amount of alkali reduction at the same time to reduce the amount of sodium hydroxide, reduce the alkalinity of wastewater.

[0053] Process:

[0054]In turn, 15g of sodium hydroxide, 1g of O1g, 10g of sodium lignosulfonate, 25g of tea saponin, add 949mL of water at room temperature under 300 rpm / min stirring for 30min to prepare the pretreatment finishing solution. Then put the polyester fabric into the pre-treatment finishing solution and put it into a 40 °C constant temperature water bath pot for 15 min, then heat up to 95 °C at 3 °C / min, continue to process for 45 min, and finally clean in water, add 2 mL of acetic acid to clean again, and ...

Embodiment 2

[0076] The preparation method is the same as Example 1, the difference is: adjust the amount of sodium hydroxide, sodium lignosulfonate and tea saponin in the alkali reduction treatment process and the treatment time (95 ° C), to test the effect of the dosage of additives on the reduction rate and strength of polyester fabrics, as shown in Table 2.

[0077] Table 2.Effect of alkali reduction process on fabric performance

[0078]

[0079] As shown in Table 2:

[0080]With the increase in the use of sodium hydroxide, sodium lignosulfonate and theophynosin, the rate of reduction and loss of strength also gradually increased. In general, the amount of sodium hydroxide is between 5 and 25g / L in polyester fabric alkali reduction treatment; with the increase of sodium hydroxide concentration, after the concentration of sodium hydroxide is greater than 20g / L, the strong damage to the fabric is larger. Comprehensive selection: When the NaOH concentration reaches 15g / L, sodium lignosulfo...

Embodiment 3

[0082] The preparation method is the same as Example 1, the difference is: adjust the amount of modified copper / polyacrylate emulsion in the modified paste, test the K / S value of the fabric, wash fastness, friction color fastness and other properties, as shown in Table 3.

[0083] Table 3.Effect of the amount of modified copper / polyacrylate emulsion on fabric performance in modified paste

[0084]

[0085] As shown in Table 3:

[0086] The addition of modified copper / polyacrylate emulsion to the modified paste allows the fabric to obtain good color, while the fabric has excellent washability and friction color fastness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com