Making methods of Lycra fiber capable of inducing generation of negative oxygen ions, negative oxygen ion functional powder and negative oxygen ion functional auxiliary agent

A technology of negative oxygen ions and production methods, which is applied to the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of insufficient induction of negative oxygen ions, achieve excellent chemical and physical properties, purify air and Environment, the effect of prolonging the half-life of radioactive rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

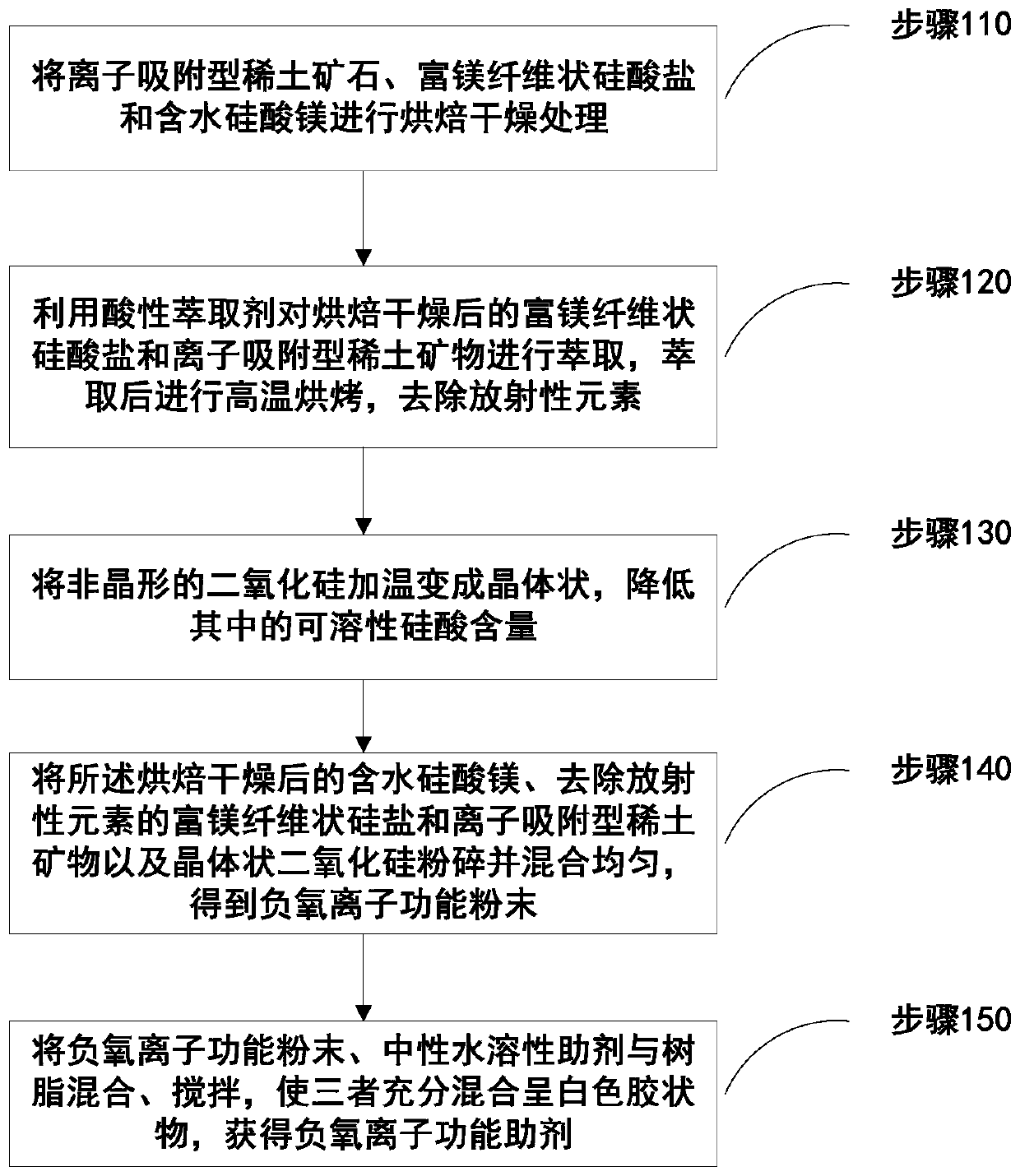

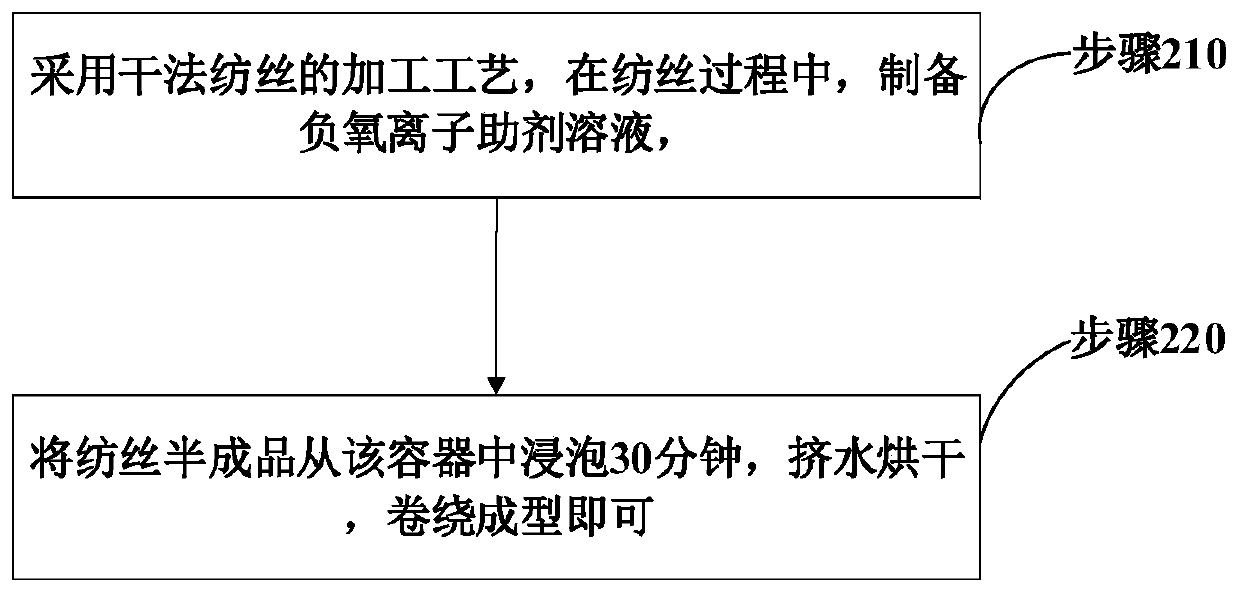

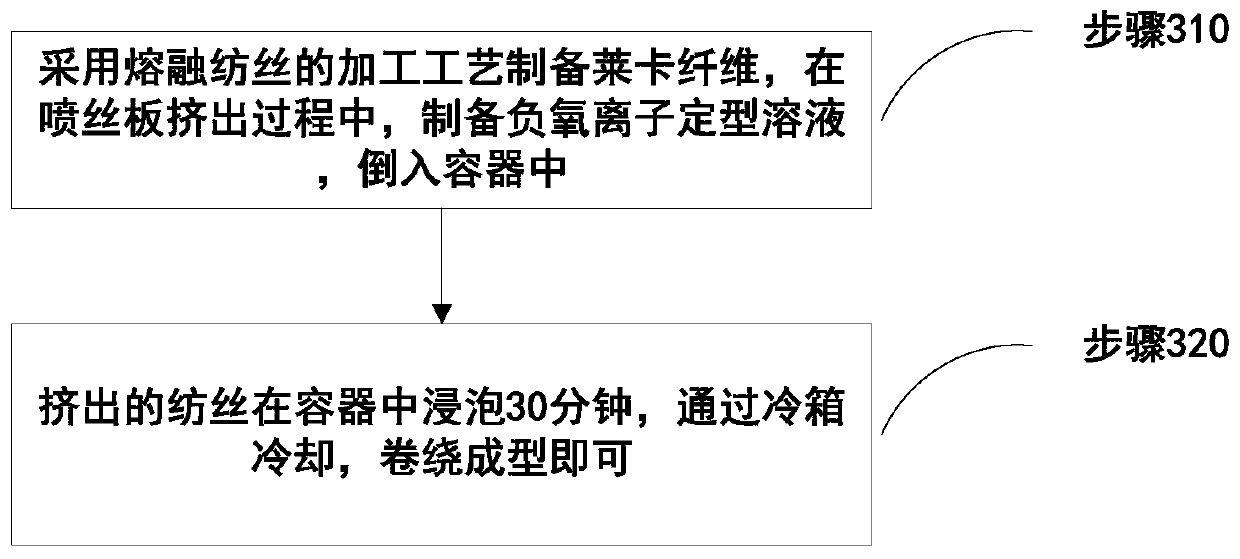

Method used

Image

Examples

specific Embodiment 1

[0072] Magnesium silicate hydrate, 3;

[0073] Magnesium-rich fibrous silicate, 5.5;

[0074] Ion-adsorbed rare earth ores, 4;

[0075] Silica, 2.5.

specific Embodiment 2

[0077] Magnesium silicate hydrate, 3;

[0078] Magnesium-rich fibrous silicate, 3;

[0079] Ion-adsorbed rare earth ores, 8;

[0080] Silica, 1.

specific Embodiment 3

[0082] Magnesium silicate hydrate, 3;

[0083] Magnesium-rich fibrous silicate, 3.5;

[0084] Ion-adsorbed rare earth ores, 7;

[0085] Silica, 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com