Small-module straight bevel gear forming method numerical control machining process

A technology of spur bevel gears and small modulus, which is applied in the field of CNC machining of small modulus spur bevel gears by forming method, can solve the problems of high flexibility, low cost, high efficiency processing requirements, low productivity, and high processing costs for changing types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

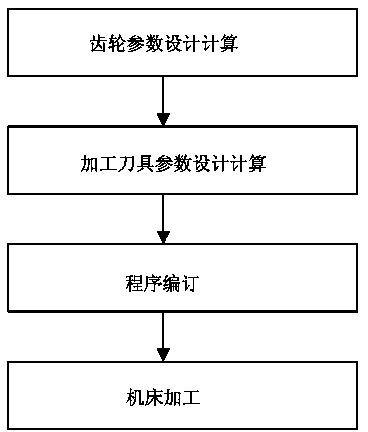

Method used

Image

Examples

Embodiment 1

[0028] Example 1: It is known that the gear modulus mo=1, the number of teeth Z=25, the pressure angle αe=20°, the axis angle Φ=90°, the dedendum height r1=1.25×mo, and the addendum height r2=1.0× mo, the measurement unit is millimeter mm;

[0029] The first step: design and calculation of gear parameters, calculate and design the indexing angle of the gear according to the parameters such as the modulus mo of the gear to be produced, the number of teeth Z, the pressure angle αe, the included angle of the axis Φ, the height of the dedendum r1, and the height of the addendum r2 α, tip circle outer diameter φα, pitch circle outer diameter φa, cone generatrix length L, tooth length L1, small end modulus mi, pitch circle inner diameter φi, addendum angle δk, root cone angle δf and other parameters, the specific calculation method is as follows :

[0030] Indexing angle: α1=360° / Z=360° / 25=14.4

[0031] Top circle outer diameter: φα= mo×Z+2×cosδo=1.0×25+0.7071=26.41mm

[0032] Pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com