Silicon carbide-nano-diamond composite coating, preparation method thereof and application thereof, cold-extrusion mould terrace die and mould

A nano-diamond and silicon carbide coating technology, applied in the direction of metal material coating process, coating, manufacturing tools, etc., can solve the problem of less use of cold extrusion dies, which is conducive to precision machining, improve production efficiency, reduce The effect of squeezing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

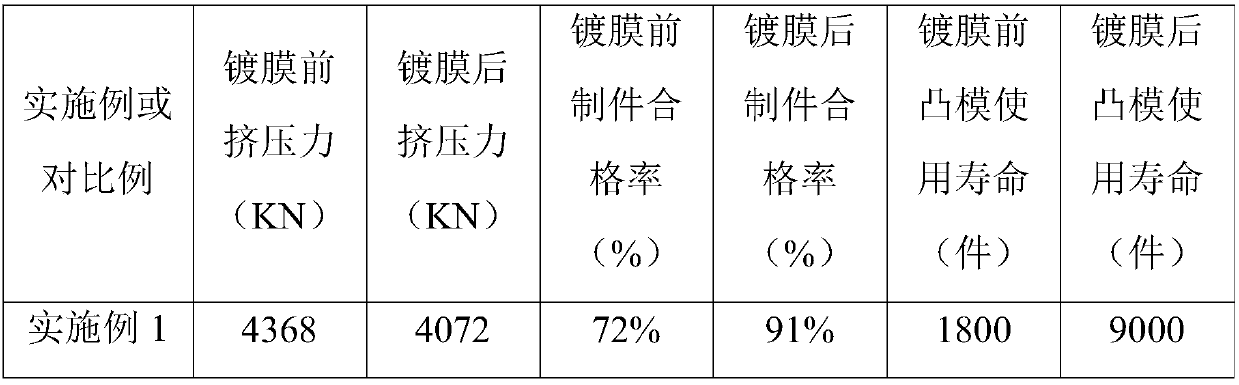

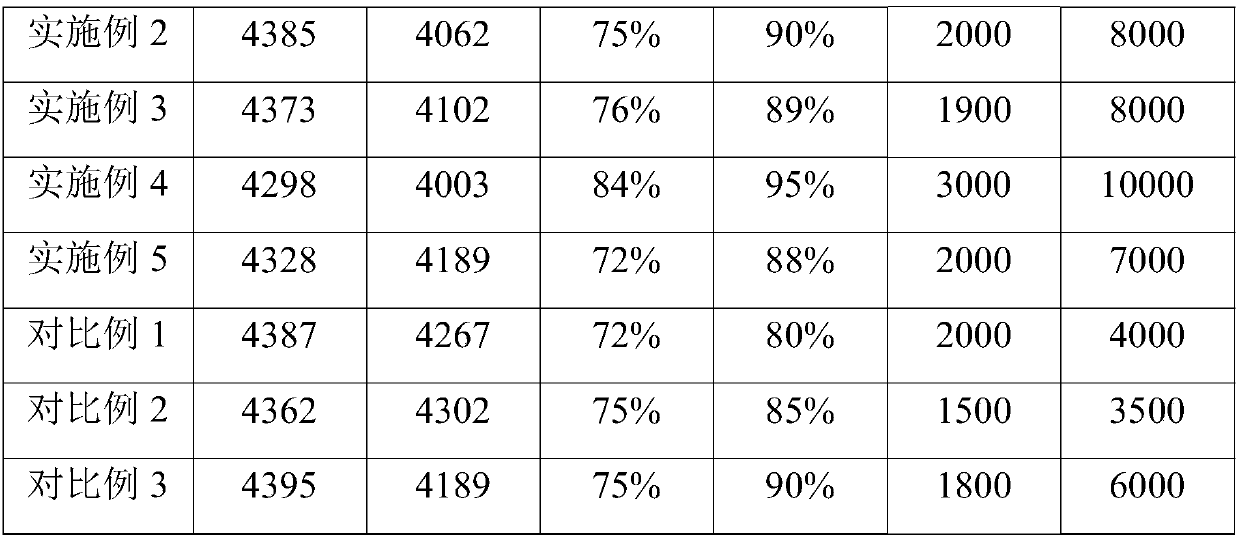

Examples

preparation example Construction

[0059] According to a second aspect of the present invention, a method for preparing the above-mentioned silicon carbide-nanodiamond composite coating is provided, comprising the following steps:

[0060] A silicon carbide coating and a nano-diamond coating are sequentially deposited on the surface of a substrate by a hot wire vapor deposition method to obtain a silicon carbide-nano-diamond composite coating.

[0061] Hot wire chemical vapor deposition (hot wire CVD) is one of the chemical vapor deposition methods. This method is mainly to thermally decompose hydrocarbon gas to produce SP which is necessary for synthetic diamond. 3 A group of carbon atoms that hybridize orbitals.

[0062] The method of hot wire chemical vapor deposition is not limited, and conventional hot wire chemical vapor deposition devices and / or processes can be used, and it can be a common hot wire method, or other improved hot wire methods such as electronic assistance.

[0063] The step of sequential...

Embodiment 1

[0108] Example 1 Preparation of silicon carbide-nano-diamond composite coating for cold pier die punch of cylindrical part

[0109] The cold extrusion die punch of the cylindrical part is used as a substrate, and a silicon carbide-nanometer diamond composite coating is prepared thereon, comprising the following steps:

[0110] (1) Carry out white corundum wet sandblasting treatment on the punch, the sandblasting pressure is 400kPa, the sand particle size is 800 mesh, and the sandblasting time is 1min; then the punch is ultrasonically cleaned in acetone and alcohol for 10min;

[0111] (2) The silicon carbide coating is prepared by the hot wire chemical vapor deposition method, and hydrogen, methane and silane are used as reaction gases to deposit a silicon carbide coating on the surface of the pretreated punch. The deposition conditions include: the methane gas flow rate is 10 sccm, The hydrogen gas flow rate is 1000 sccm, the silane gas flow rate is 10 sccm, the vacuum chamber...

Embodiment 2

[0114] Example 2 Preparation of Silicon Carbide-Nanodiamond Composite Coating of Cylindrical Part Cold Pier Die Punch

[0115] The cold pier mold punch of the cylindrical part is used as a substrate, and a silicon carbide-nanodiamond composite coating is prepared thereon, comprising the following steps:

[0116] (1) Carry out wet sandblasting treatment of white corundum on the punch, the sandblasting pressure is 300kPa, the sand particle size is 900 mesh, and the sandblasting time is 1min; then the punch is ultrasonically cleaned in acetone and alcohol for 15min;

[0117] (2) The silicon carbide coating is prepared by hot wire chemical vapor deposition, with hydrogen, methane and silane as reaction gases, and the silicon carbide coating is deposited on the surface of the pretreated punch. The deposition conditions include: methane gas flow rate is 20sccm, The hydrogen gas flow rate is 1000 sccm, the silane gas flow rate is 20 sccm, the vacuum chamber pressure is kept at 4kPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com