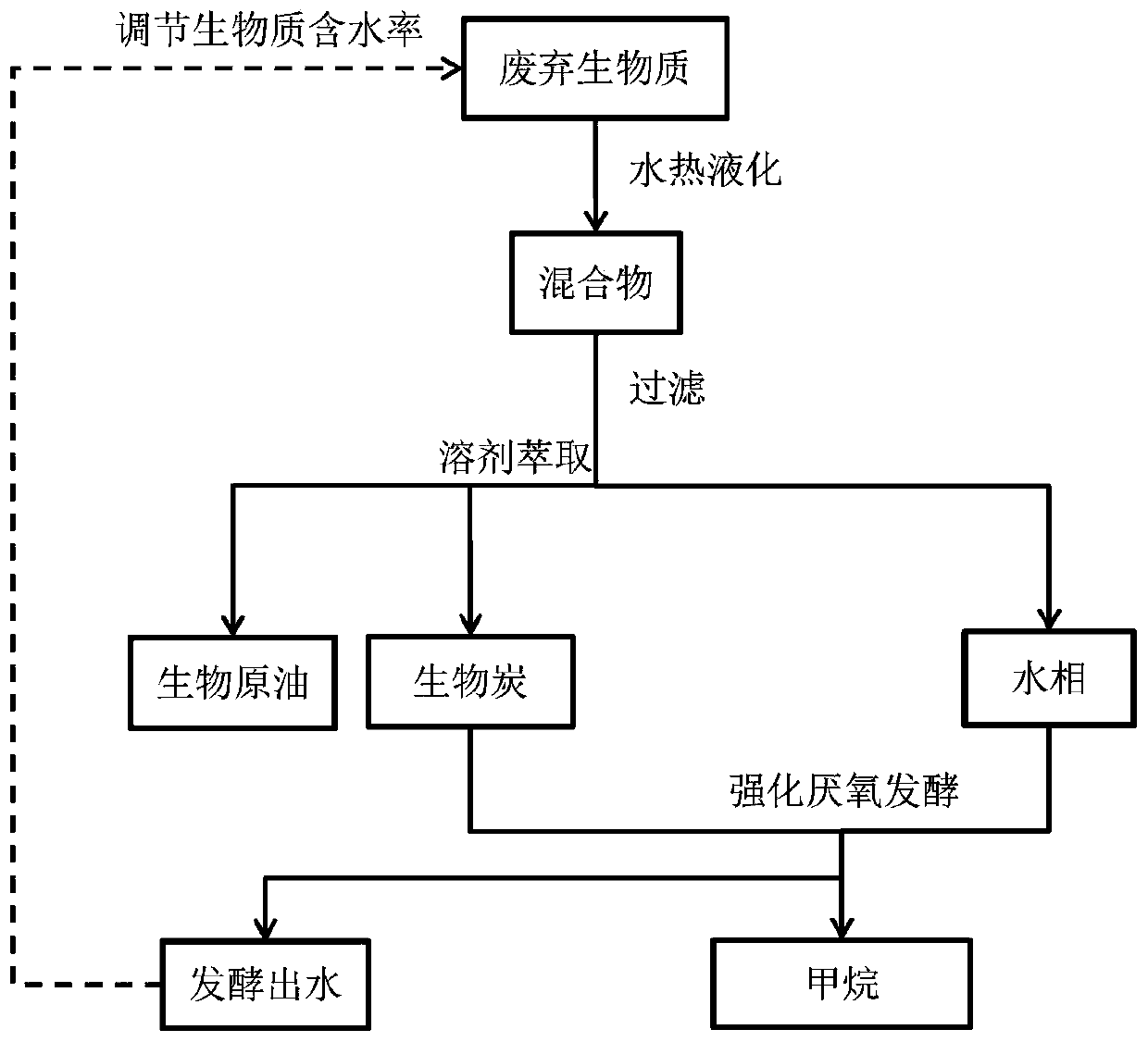

Method for producing bio crude oil and methane jointly from waste biomass

A technology for waste biomass and bio-crude oil, which is applied in the preparation of waste fuel, liquid hydrocarbon mixture, petroleum industry, etc., to achieve the effect of accelerating electron transfer, protecting the environment and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Mix 10g of straw and 40g of water (the moisture content of the substrate is 81%), put it in a reaction kettle, carry out hydrothermal liquefaction (220°C, 30min), cool naturally to room temperature, and filter to obtain aqueous phase products and non-aqueous phase products ;

[0041] After the non-aqueous phase product is extracted with acetone, it is filtered and distilled in sequence to obtain bio-crude oil and bio-char;

[0042] Mix 500g of water phase and 500g of straw charcoal, and carry out anaerobic fermentation (hydraulic retention time is 3d, temperature is 30°C, and the number of effluent cycles is 5 times) to obtain methane. Compared with the control group without adding any biochar, the gas production peak of straw charcoal-enhanced anaerobic fermentation was 7 days earlier, and the removal rate of COD in water phase was 75.6%.

Embodiment 2

[0044] Mix 10g of sawdust and 20g of water (moisture content of the substrate is 70%), put it in a reaction kettle, carry out hydrothermal liquefaction (320°C, 300min), naturally cool to room temperature, and filter to obtain aqueous phase products and non-aqueous phase products ;

[0045] After the non-aqueous phase product is extracted with acetone, it is filtered and distilled in sequence to obtain bio-crude oil and bio-char;

[0046] Mix 500g of water phase with 250g of peanut shell charcoal, and carry out anaerobic fermentation (hydraulic retention time is 4d, temperature is 40°C, and the number of effluent cycles is 4 times) to obtain methane. Compared with the control group without adding any biochar, the gas production peak of the enhanced anaerobic fermentation with peanut shell charcoal was 5 days earlier, and the removal rate of COD in the water phase was 72.8%.

Embodiment 3

[0048] Mix 10g of pig manure and 30g of water (the moisture content of the substrate is 95%), put it into a reaction kettle, carry out hydrothermal liquefaction (400°C, 90min), cool naturally to room temperature, and filter to obtain the aqueous phase product and the non-aqueous phase product;

[0049] After the non-aqueous phase product is extracted with acetone, extraction and distillation are performed in sequence to obtain bio-crude oil and bio-coke;

[0050] Mix 500g of water phase with 167g of coconut shell charcoal, and carry out anaerobic fermentation (hydraulic retention time is 3d, temperature is 55°C, and the number of effluent cycles is 10 times) to obtain methane. Compared with the control group without adding any biochar, the gas production peak of enhanced anaerobic fermentation with peanut shell charcoal was 6 days earlier, and the removal rate of COD in water phase was 83.7%.

[0051] As can be seen from the above examples, the method provided by the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com