Method for preparing reusable and efficient carbon-nitride-based composite photocatalyst

A technology of composite photocatalyst, applied in the field of photocatalysis, can solve the problems of short free diffusion distance of photogenerated carriers and poor photocatalytic activity, and achieve the effects of avoiding complicated valence state, simple preparation process and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

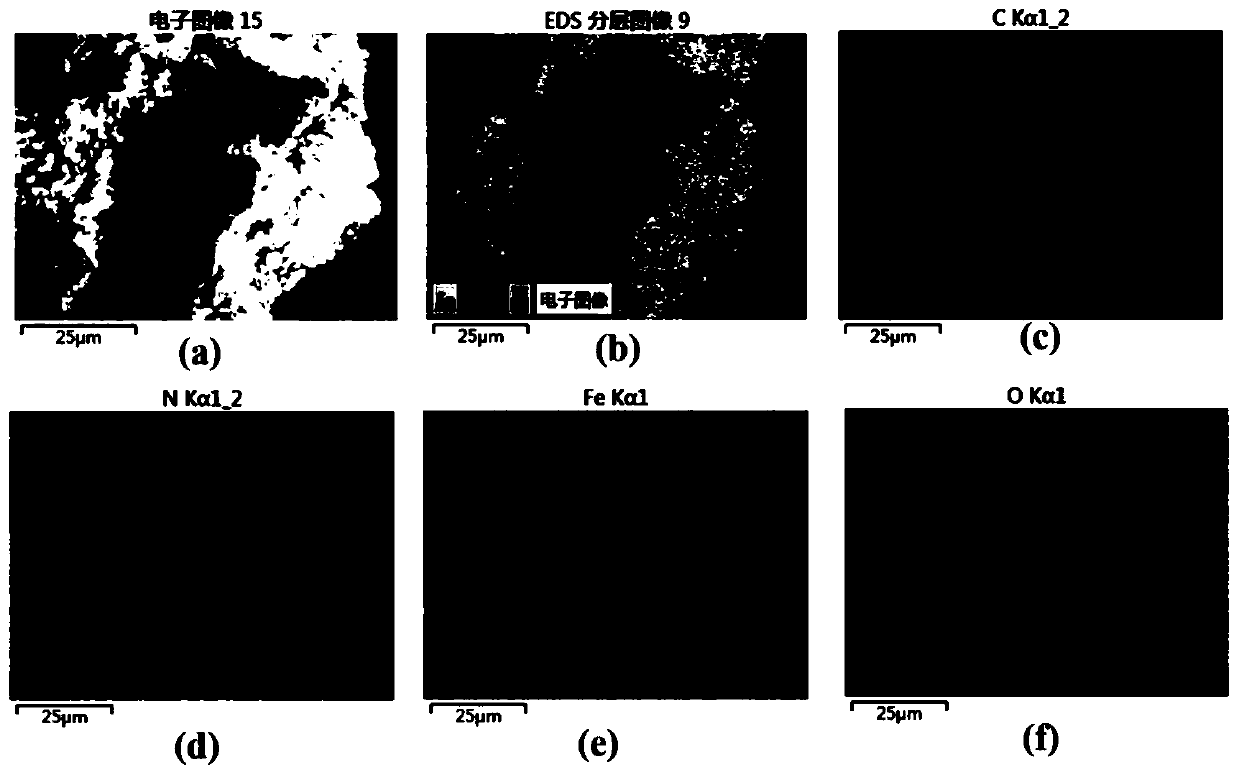

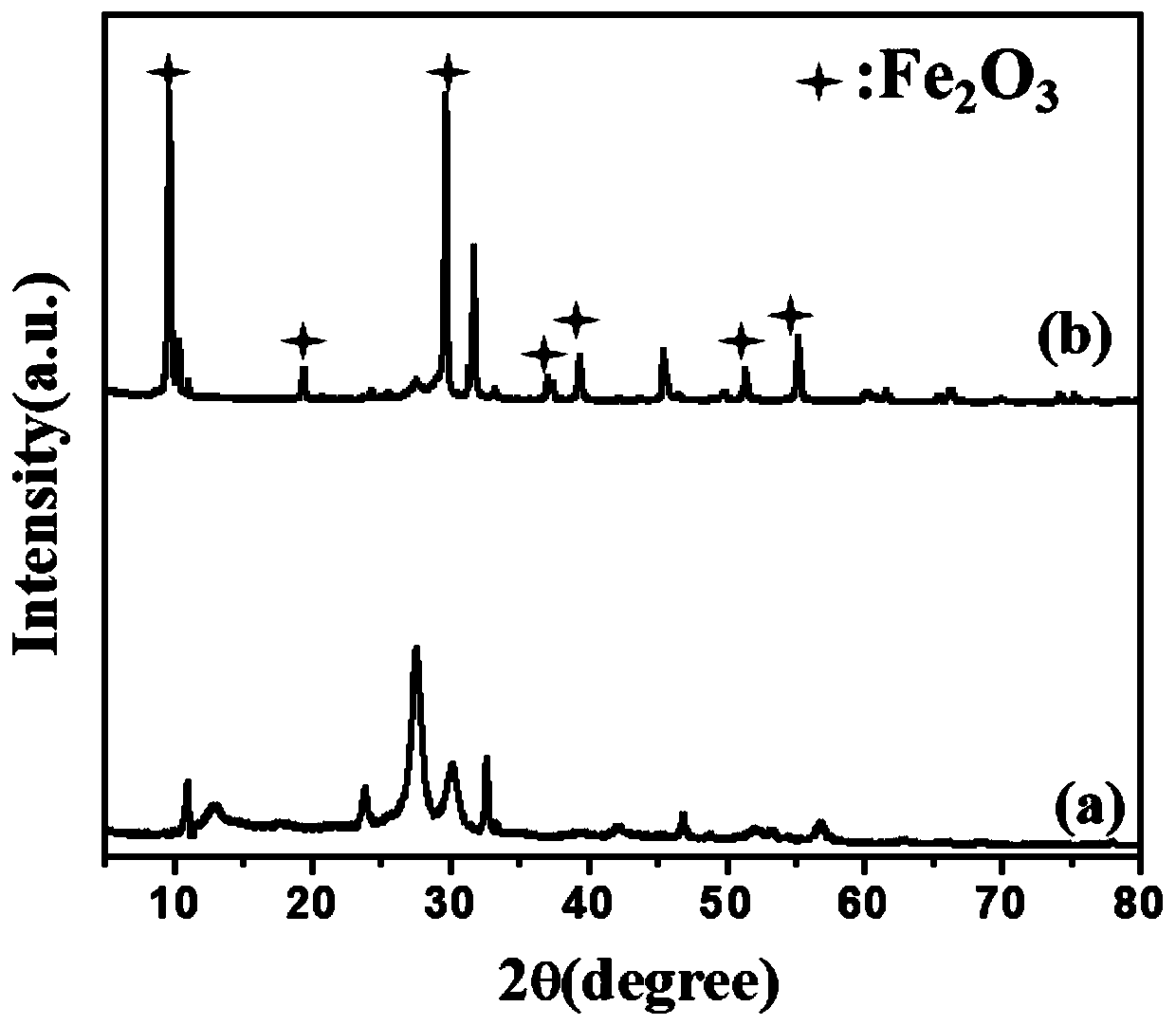

[0033] Example 1g-C 3 N 4 Preparation of base composite photocatalyst 1

[0034] Add 5g of urea to a 50ml beaker, add 10ml of deionized water, and stir vigorously for 15min to obtain a clear solution; add 0.5g of Fe(NO 3 ) 3 , continue to stir for 15 minutes, after fully mixing, place the beaker in a vacuum drying oven; continue drying in the drying oven at 120°C until the solution is completely evaporated, and collect the powder; put the obtained powder into a dry and clean flat-bottomed crucible, and seal it tightly with aluminum foil. wrapped, and then placed in a closed tube furnace; in a nitrogen atmosphere, calcined at a high temperature of 550 °C for 2 h, with a heating rate of 5 °C / min, and naturally cooled to room temperature; the obtained product was washed with absolute ethanol and deionized water for 3 times, centrifuged, and then placed in a vacuum drying oven at 80 ° C for 12 hours to obtain the g-C of the present invention 3 N 4 based composite photocatalys...

Embodiment 2

[0035] Example 2g-C 3 N 4 Preparation of base composite photocatalyst 2

[0036] Add 5g of melamine into a 50ml beaker, add 10ml of deionized water, and stir vigorously for 15min to obtain a clear solution; add 0.5g of FeCl to the solution 3 ·6H 2 O, continue to stir for 15 minutes, after fully mixing evenly, place the beaker in a vacuum drying oven; continue drying in the drying oven at 120°C until the solution is completely evaporated, and collect the powder; put the obtained powder into a dry and clean flat-bottomed crucible, and seal it tightly with aluminum foil. wrapped, and then placed in a closed tube furnace; in an argon atmosphere, calcined at a high temperature of 550 °C for 2 h, with a heating rate of 5 °C / min, and naturally cooled to room temperature; the obtained product was washed with absolute ethanol and deionized water 3 times, centrifuged, and then placed in a vacuum drying oven at 80 ° C for 12 hours to obtain the Fe of the present invention 2 o 3 / g -...

Embodiment 3

[0039] Example 3g-C 3 N 4 Preparation of base composite photocatalyst 3

[0040] Add 2.5g of melamine into a 50ml beaker, add 10ml of deionized water, and stir vigorously for 15min to obtain a clear solution; add 0.5g of Fe(CH 3 COO) 3 , continue to stir for 15 minutes, after fully mixing evenly, put the beaker in a vacuum drying oven; continue drying in the drying oven at 120°C until the solution is completely evaporated, and collect the powder; put the obtained powder into a dry and clean flat-bottomed crucible, and wrap it tightly with aluminum foil , and then placed in a closed tube furnace; in a helium atmosphere, calcined at a high temperature of 550 ° C for 2 h, the heating rate was 5 ° C / min, and naturally cooled to room temperature; the obtained product was washed with absolute ethanol and deionized water for 3 time, centrifuged, and then placed in a vacuum drying oven at 80 ° C for more than 12 hours to obtain the sample of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com