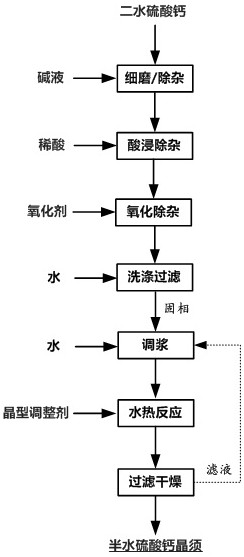

Method for preparing calcium sulfate hemihydrate whiskers with high aspect ratio by utilizing calcium sulfate dihydrate

A technology of calcium sulfate dihydrate and calcium sulfate hemihydrate, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of product purity, low aspect ratio, high requirements, etc., and achieve product added value High, extended raw material range, efficient and thorough removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment utilizes the desulfurization gypsum of the power plant as a raw material to prepare the method for calcium sulfate hemihydrate whiskers with high aspect ratio, and the specific steps are as follows:

[0035] (1) Fine grinding / removal of impurities: According to the ratio of liquid to solid ratio of 1, mix desulfurized gypsum with 10% sodium hydroxide solution and add it to the stirring mill for fine grinding, control the fine grinding time to 0.5h, and discharge Particle size D90<200 mesh;

[0036] (2) Acid leaching to remove impurities: filter the slurry obtained in step (1), add dilute hydrochloric acid with a concentration of 10% in the obtained solid phase, adjust the liquid-solid ratio to 1, perform acid leaching and remove impurities, and control the reaction temperature The temperature is 50℃, and the leaching time is 1h, so that the impurity components such as carbonates and oxides in the raw materials can be further reacted and removed; ...

Embodiment 2

[0043] Present embodiment utilizes natural gypsum as raw material, the method for preparing calcium sulfate hemihydrate whisker with high aspect ratio, concrete steps are as follows:

[0044] (1) Fine grinding / removal of impurities: According to the ratio of liquid to solid ratio of 1.5, mix natural gypsum with 15% sodium hydroxide solution and add it to the stirring mill for fine grinding and removal of impurities. The particle size of the material is D90<200 mesh, and the impurities such as alumina and silicon dioxide in the raw material are fully removed;

[0045] (2) Acid leaching to remove impurities: filter the slurry obtained in step (1), add dilute hydrochloric acid with a concentration of 10% in the obtained solid phase, adjust the liquid-solid ratio to 2, perform acid leaching to remove impurities, and control the leaching time For 2h, realize that impurity components such as carbonate and iron oxide in the raw material are fully removed;

[0046] (3) Oxidation and ...

Embodiment 3

[0052] In this embodiment, titanium gypsum is used as a raw material to prepare the method for calcium sulfate hemihydrate whiskers with high aspect ratio, and the specific steps are as follows:

[0053] (1) Fine grinding / removal of impurities: According to the ratio of liquid to solid ratio of 1, mix natural gypsum with 10% sodium hydroxide solution into the ball mill for fine grinding, control the fine grinding time to 0.5h, and the output particle size D90<200 mesh;

[0054] (2) Acid leaching to remove impurities: take the slurry obtained in step (1) for solid-liquid separation, add dilute sulfuric acid with a concentration of 10% to the obtained solid phase at room temperature, adjust the liquid-solid ratio to 2, and perform acid leaching to remove impurities process, control the leaching time to 2 hours, and realize the further reaction and removal of impurity components such as carbonates and oxides in the raw materials;

[0055] (3) Oxidation and impurity removal: soli...

PUM

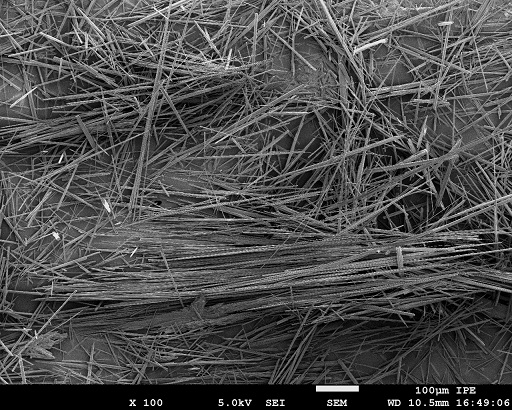

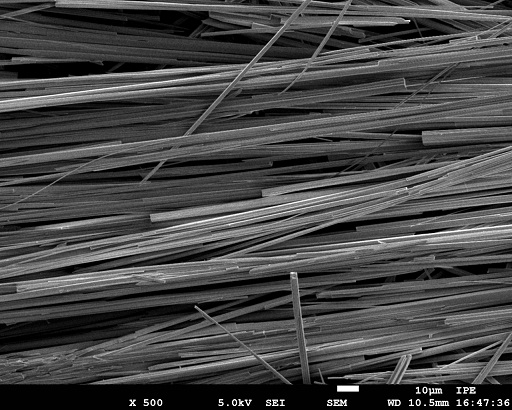

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com