Lightweight paper made from high-proportion bamboo pulp and making method of lightweight paper

A light paper, high proportion technology, applied in the field of papermaking, can solve the problems of high production cost, achieve the effect of low product cost, small pollution load, and expand the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

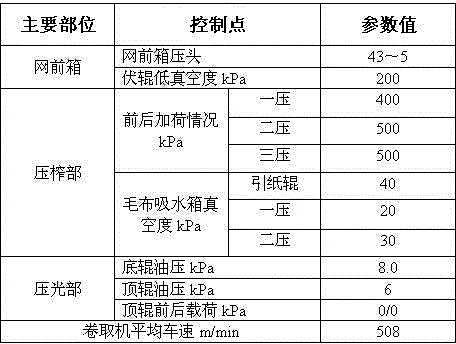

Embodiment 1

[0020] The chemical bamboo pulp that is 35 ° SR, ISO whiteness of 84% and the mechanical pulp that is 34 ° SR, ISO whiteness of 65% and 40 ° SR, ISO whiteness of 40 ° SR are beaten respectively. 70% long-fiber CTMP pulp is prepared according to the ratio of 50:45:5 to prepare 5000 kg of mixed pulp, add 60 kg of starch, 500 kg of talcum powder, 35 kg of dispersed rosin gum, 35 kg of aluminum sulfate and an appropriate amount of polyacrylamide to prepare the net size , the amount of polyacrylamide added is 0.2kg / t paper, the amount of disperse rosin glue is the amount added according to the sizing degree of 0.5mm, the quality index of the screen size is pH 5.8, the concentration is 0.7-0.9%, and the buckle degree is 52 °SR, net pulp is produced by 3940mm fourdrinier paper machine.

Embodiment 2

[0022] The chemical bamboo pulp with 30°SR and ISO brightness of 80% and the mechanical pulp with 39°SR and ISO brightness of 70% and the pulp with 35°SR and ISO brightness of 75% were beaten respectively. The long-fiber CTMP pulp is prepared according to the ratio of 55:40:5 to prepare 5000 kg of mixed pulp, add 60 kg of starch, 500 kg of talcum powder, 40 kg of dispersed rosin gum, 30 kg of aluminum sulfate and an appropriate amount of polyacrylamide to prepare the net size, polypropylene The amount of amide added is 0.2kg / t paper, the amount of disperse rosin glue is added according to the sizing degree of 0.5mm, the quality index of the screen size is pH 6.2, the concentration is 0.7-0.9%, and the buckle degree is 55°SR. The screen pulp is produced by a 3940mm fourdrinier paper machine.

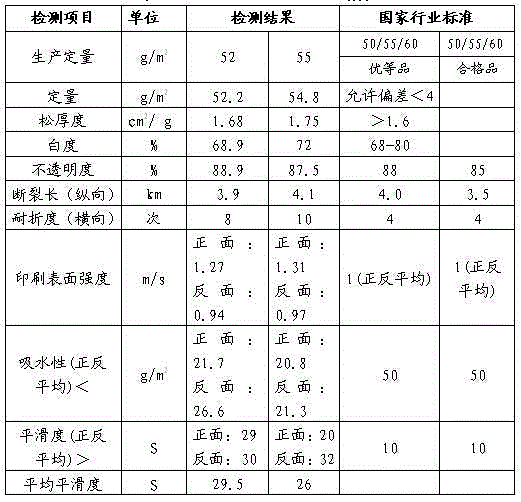

[0023] The main process parameters of the paper machine papermaking machine used in embodiment 1 and embodiment 2 are as shown in table 1:

[0024] Table 1 Main process parameters table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com