Cement particle board and preparation method thereof

A particleboard and cement technology, applied in the field of cement particleboard and its preparation, can solve the problems of high cost, cumbersome process, long production cycle, etc., and achieve the effects of low manufacturing cost, reduced environmental pollution, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

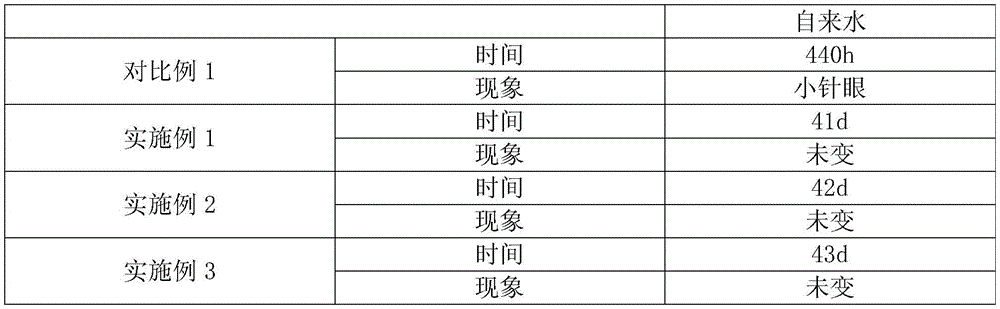

Embodiment 1

[0032] A cement particleboard, comprising the following components by weight: 10 parts of wood shavings, 15 parts of high-calcium fly ash, 30 parts of sulphoaluminate cement, 2 parts of water glass and 0.2 part of calcium chloride; the cement Particle board also comprises the following components by weight: 0.1 part of auxiliary agent; described auxiliary agent is sodium chloride; described wood particle is prepared from fast-growing wood, and the size of described wood particle is: long 10 mm, wide 2 mm, thick 0.2 mm; the content of calcium oxide in the described high-calcium fly ash is 15%; the mass percent concentration of the described water glass is 35%, and the solvent is water; the described chlorinated The mass percent concentration of calcium is 30%, and the solvent is water; the sulphoaluminate cement is a fast-hardening special cement, and the strength can reach 42.5 MPa after 3 days.

[0033] The preparation method of described cement particleboard, comprises the f...

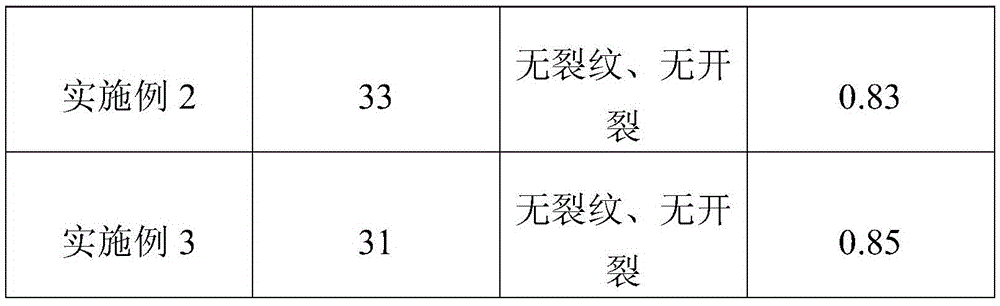

Embodiment 2

[0039] A cement particle board, comprising the following components by weight: 40 parts of wood shavings, 50 parts of high-calcium fly ash, 55 parts of sulphoaluminate cement, 5 parts of water glass and 2.2 parts of calcium chloride; the cement The particle board also comprises the following components by weight: 2 parts of auxiliary agent; the auxiliary agent is raw gypsum; the wood shavings are prepared from branch wood, and the size of the wood shavings is: 80 mm long, Wide 8 millimeters, thick 0.5 millimeter; The content of calcium oxide is 40% in the described high-calcium fly ash; The mass percent concentration of described water glass is 35%, and solvent is water; The described calcium chloride The mass percent concentration is 30%, and the solvent is water; the sulphoaluminate cement is a fast-hardening special cement, and the strength can reach 42.5 MPa after 3 days.

[0040] The preparation method of described cement particleboard, comprises the following steps:

[...

Embodiment 3

[0046]A cement particleboard, comprising the following components by weight: 30 parts of wood shavings, 30 parts of high-calcium fly ash, 40 parts of sulphoaluminate cement, 3 parts of water glass and 1.5 parts of calcium chloride; the cement The particle board also comprises the following components by weight: 1 part of auxiliary agent; said auxiliary agent is calcium hydroxide; said wood shavings are prepared from shrubs, and the size of said wood shavings is: 40 mm long , wide 4 millimeters, thick 0.4 millimeter; The content of calcium oxide is 30% in the described high-calcium fly ash; The mass percent concentration of described water glass is 35%, and solvent is water; Described calcium chloride The mass percentage concentration is 30%, and the solvent is water; the sulphoaluminate cement is a rapid-hardening special cement, and the strength can reach 42.5MPa after 3 days.

[0047] The preparation method of described cement particleboard, comprises the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com