Glycyrrhetinic acid preparation method

A technology of glycyrrhetinic acid and licorice extract, which is applied in the field of biomedicine, can solve the problems of long hydrolysis time, long conversion time, and low efficiency, and achieve the effects of reducing solvent consumption, shortening reaction time, and expanding the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, the preparation of glycyrrhetinic acid

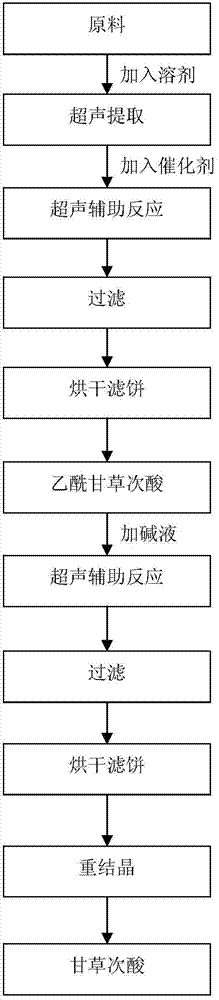

[0039] Such as figure 1 As shown, take licorice cream (9% glycyrrhizic acid content, HPLC method) 400g, add 50% (v / v) acetic acid aqueous solution 2400mL, set ultrasonic power to 300W to extract 60min, filter to remove filter residue, then add catalyst concentrated sulfuric acid (98.3wt %) 12mL, set the ultrasonic power to 300W, and react for 60min. The obtained solid acetylglycyrrhetinic acid was filtered, washed with 200 mL of water, and dried at a material temperature of 60°C. 25.12 g of acetylglycyrrhetinic acid was obtained with a purity of 90.5%.

[0040] Weigh 20.3g of the above-mentioned acetylglycyrrhetinic acid; add NaOH solution (20.3mL) with a concentration of 5mol / L; put it into an ultrasonic reactor for reaction for 60min, and the ultrasonic power is 100W; Cake to remove salts; filter cake drying to obtain crude product glycyrrhetinic acid 17.8g; crude product glycyrrhetinic acid was added 20 times ...

Embodiment 2

[0041] Embodiment 2, the preparation of glycyrrhetinic acid

[0042] Such as figure 1 As shown, take glycyrrhizic acid powder (22% glycyrrhizic acid content, HPLC) 200g, add 70% (v / v) acetic acid aqueous solution 1000mL, set the ultrasonic power to 500W to extract 45min, filter to remove filter residue, then add catalyst concentrated sulfuric acid (98.3wt %) 6mL, set the ultrasonic power to 500W, and react for 45min. The obtained solid acetylglycyrrhetinic acid was filtered, washed with 300 mL of water, and dried at a material temperature of 60°C. 38.46 g of acetylglycyrrhetinic acid was obtained with a purity of 92.3% (HPLC).

[0043]Weigh 20.5g of the above-mentioned acetylglycyrrhetinic acid; add KOH solution (41mL) with a concentration of 4mol / L; put it into an ultrasonic reactor for 90min, and the ultrasonic power is 300W; after the reaction is completed, lower it to 25°C, filter, and wash the filter cake with water , to remove salts; the filter cake was dried to obtai...

Embodiment 3

[0044] Embodiment 3, the preparation of glycyrrhetinic acid

[0045] Such as figure 1 As shown, get 200 g of monoammonium glycyrrhizic acid (70% HPLC content of glycyrrhizic acid), add 800 mL of 90% (v / v) acetic acid aqueous solution, set the ultrasonic power to 700 W and extract for 30 min, remove the filter residue by filtration, then add catalyst concentrated sulfuric acid (98.3 wt%) 12mL, set the ultrasonic power to 700W, and react for 30min. Filter the obtained solid acetylglycyrrhetinic acid, rinse with 400 mL of water, and dry at a material temperature of 60°C. 60.38 g of acetylglycyrrhetinic acid was obtained with a purity of 95.5% (HPLC).

[0046] Weigh 20.4g of the above-mentioned acetylglycyrrhetinic acid; add NaOH solution (81.6mL) with a concentration of 2mol / L; put it into an ultrasonic reactor for reaction for 60min, and the ultrasonic power is 500W; Cake to remove salts; the filter cake was dried to obtain crude product glycyrrhetinic acid 18.1g; crude produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com