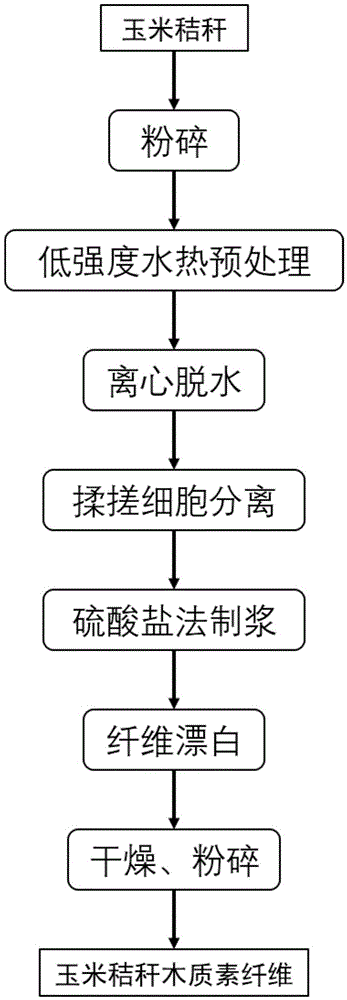

Method for preparing lignin fibers for roads from corn straws

A technology of lignin fiber and corn stalks, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as lack of wood, and achieve the effect of expanding the scope of raw materials, improving the utilization rate of raw materials, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The corn stalks harvested in the same year were chopped to 3-5 cm using a JL-800 straw grinder. Put the crushed corn stalks into a hydrothermal reactor, add tap water to make the water content about 50%, feed steam to heat to 160°C, and treat for 10min (the treatment intensity is log(10*exp((160-100) / 14.75)=2.77). After the hydrothermal treatment, the corn stalks are centrifugally dehydrated to about 25% of water content, and then the corn stalks are rubbed with the HX-600 straw rubbing machine. During the rubbing process, the cell structure of the corn stalks is destroyed and separated, and some fibers Cells and miscellaneous cells are separated, and the material after kneading is part fibrous straw tissue and part granular straw tissue. The sieve with an aperture of 5mm is used to screen the kneaded material, and the fibrous material (containing a high proportion of Fiber cell) is used for the preparation of lignin fiber, and the granular material (containing a high ...

Embodiment 2

[0016] The corn stalks harvested in the same year were chopped to 3-5 cm using a JL-800 straw grinder. Put the crushed corn stalks into a hydrothermal reactor, add tap water to make the water content about 50%, feed steam to heat to 150°C, and treat for 10min (the treatment intensity is log(10*exp((150-100) / 14.75)=2.47). After the hydrothermally treated corn stalks are centrifugally dehydrated to a water content of about 25%, the corn stalks are rubbed with the HX-600 straw rubbing machine. During the rubbing process, the cell structure of the corn stalks is destroyed and separated, and some fibers Cells and miscellaneous cells are separated, and the material after kneading is part fibrous straw tissue and part granular straw tissue. Use a sieve with an aperture of 10mm to screen the kneaded material, and the fibrous material (containing a high proportion of Fiber cells) are used for the preparation of lignin fibers, and the rubbed granular materials (containing a high propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com