Cinder ladle raw material processing method suitable for copper smelting working conditions

A technology of working conditions and processing methods, which is applied in the field of industrial smelting waste slag storage devices, can solve the problems of slag bag deformation, low wear life, not long, etc., and achieve the effect of reducing content, reducing crack tendency, and uniform and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

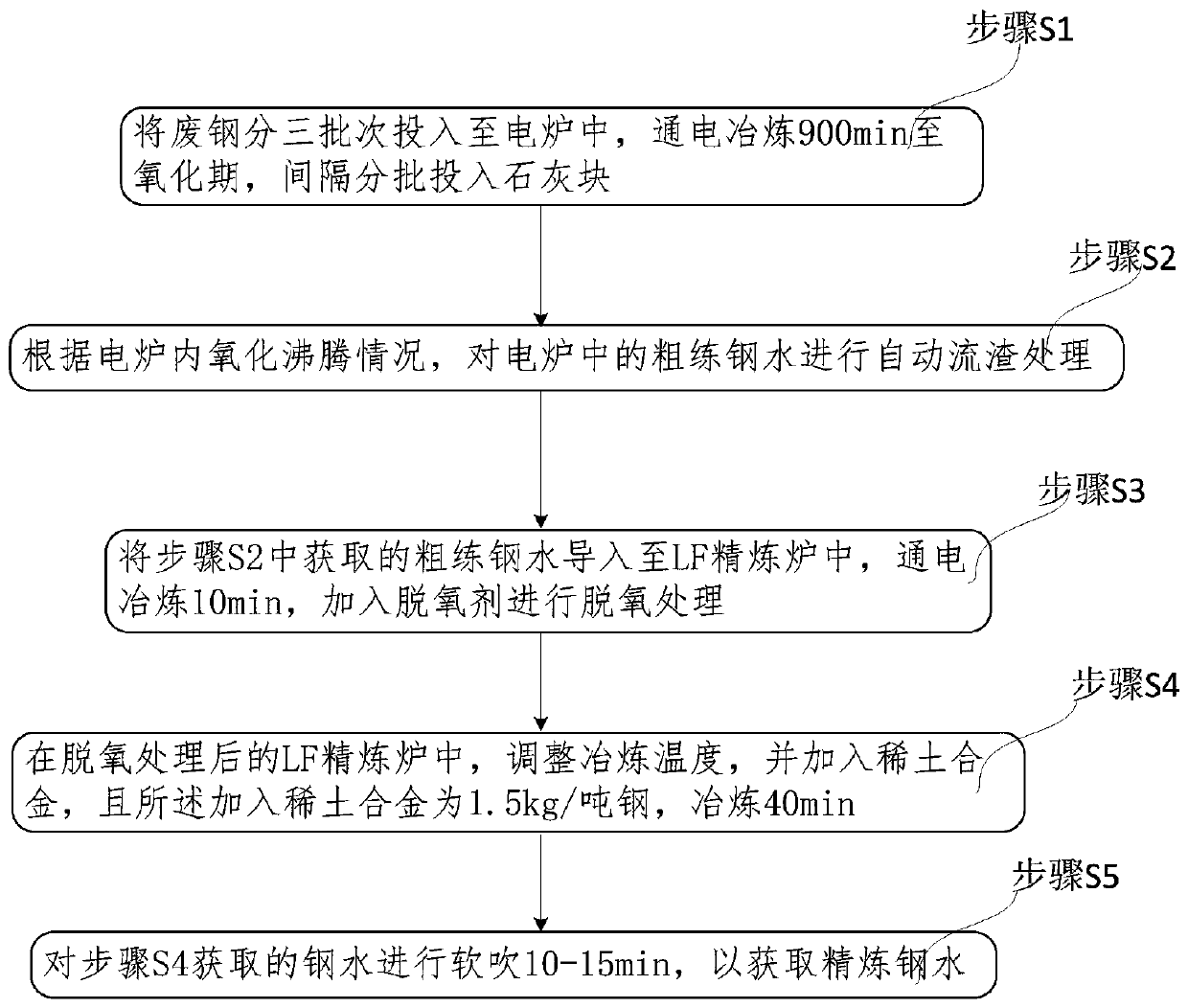

[0029] see figure 1 As shown, the present invention provides according to one aspect of the present invention, provides a kind of slag ladle raw material processing method suitable for copper smelting working conditions, comprises the following steps:

[0030] Step S1, put steel scrap into the electric furnace in three batches, electrify and smelt for 900 minutes until the oxidation period, and put lime blocks in batches at intervals, wherein 500-800 kg of lime blocks are added each time, and the interval between each batch is greater than 8 minutes. By using Lime block and melted molten steel are fully mixed, dicalcium silicate in steel slag absorbs calcium oxide to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com