A steel plate combined shear wall

A technology of combining shear walls and steel plates, applied in the direction of walls, building components, buildings, etc., can solve the problems of insufficient to ensure the joint work of concrete, high difficulty in construction of steel bars through steel plates, and difficulty in ensuring construction quality, so as to enhance anti-slippage. ability, improve connection quality, construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

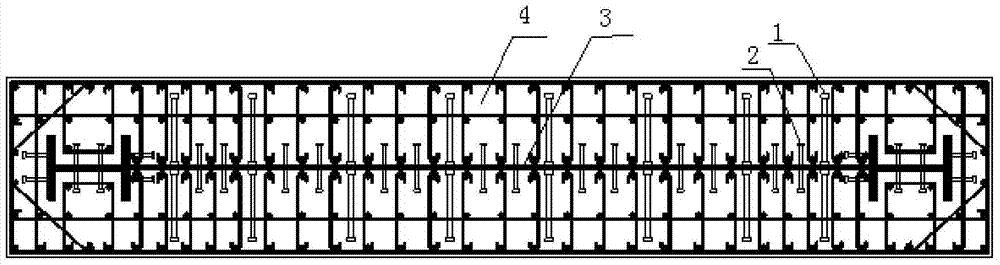

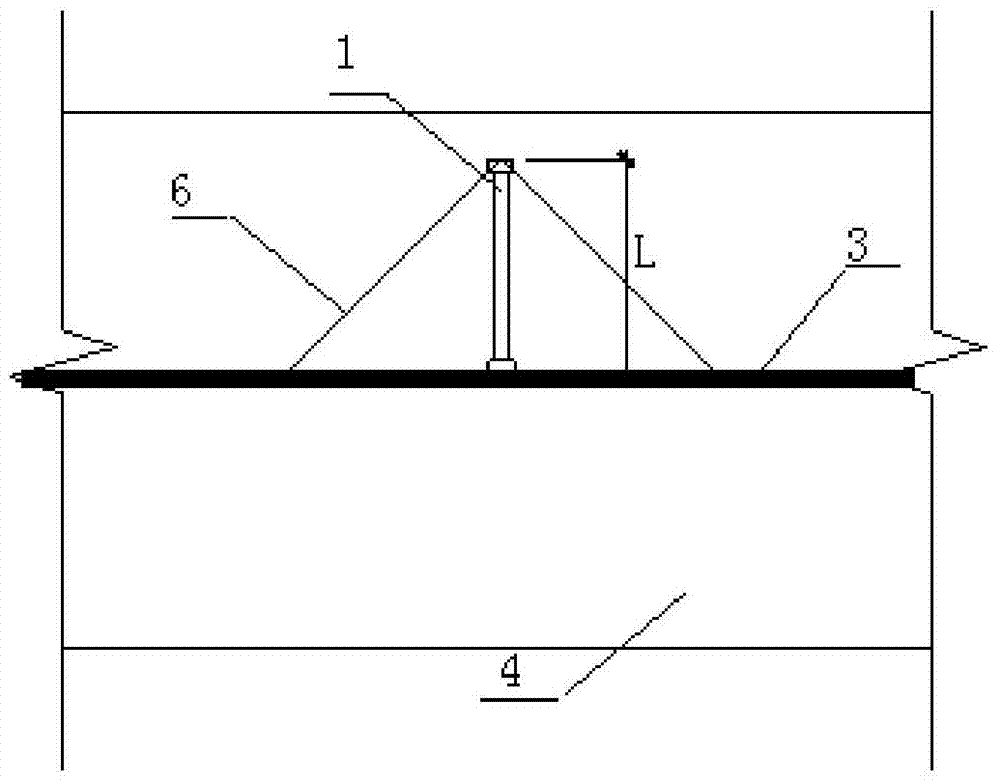

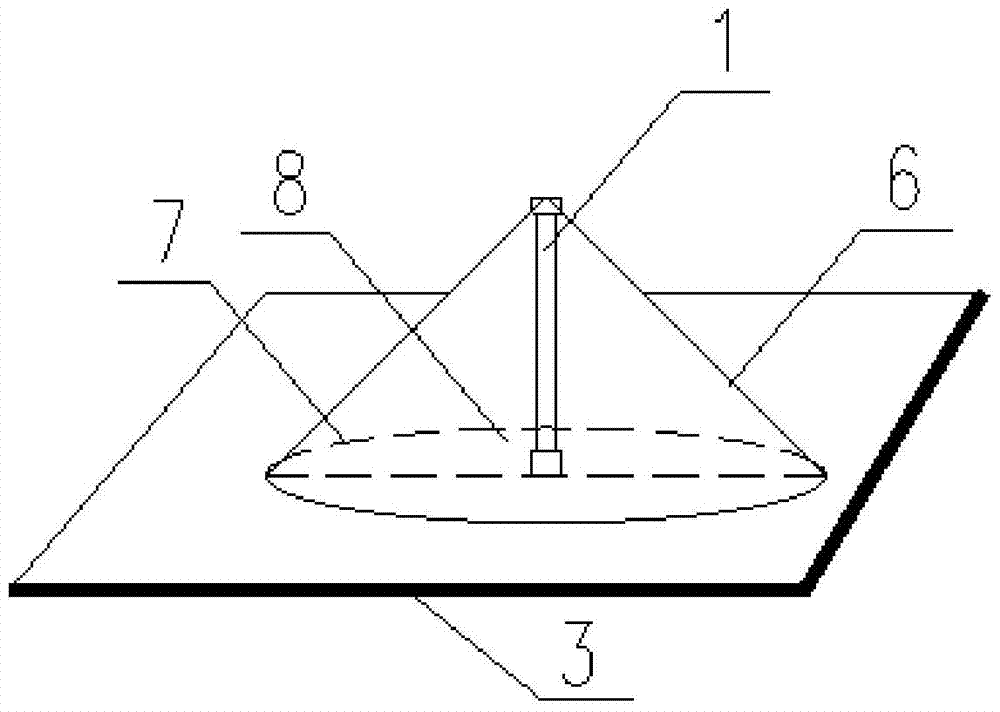

[0029] Refer to attached figure 1 It can be seen that the super-thick steel plate composite shear wall of the present invention includes a reinforced concrete wall 4 and an ultra-thick steel plate 3 embedded in the concrete wall 4, and long studs 1 are evenly arranged on both sides of the ultra-thick steel plate 3, and the long studs 1 Universal short pegs 2 are evenly arranged between them. The long stud 1 can be fixedly connected to the steel plate 3 through a steel bar connector, and the general short stud 2 can be fixedly connected to the steel plate 3 by welding or the like.

[0030] In order to ensure that the free end of the long stud 1 is within the outermost steel mesh of the concrete wall 4 and that the long stud 1 does not affect the pouring of concrete, the length of the long stud 1 is L≤h-a, where h represents the long stud The thickness of the concrete wall on the side where a represents the thickness from the outermost steel mesh to the outer surface of the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com