Flame-retardant epoxy resin compound and preparation method and application thereof

A technology of flame-retardant epoxy resin and epoxy resin, which is applied in the field of flame-retardant materials, can solve the problems of large amount of addition, poor thermal stability, difficult performance, etc., and achieve low amount of black phosphorus addition, good temperature stability and flame retardancy Good performance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

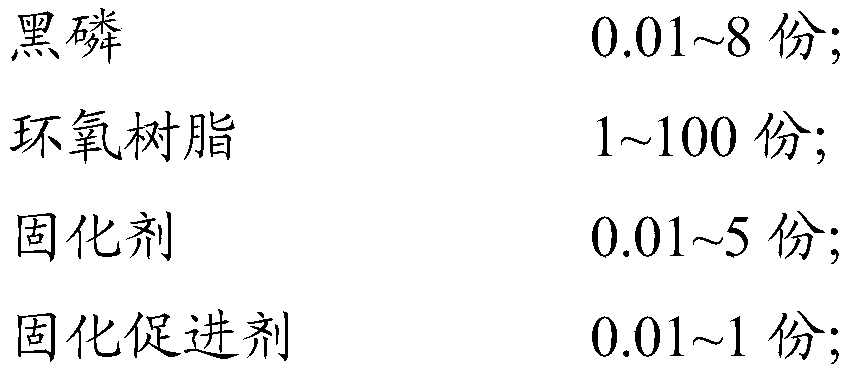

[0032] The present invention also provides a method for preparing the flame-retardant epoxy resin compound described in the above technical solution, comprising the following steps:

[0033] After mixing various raw material components for preparing the flame-retardant epoxy resin compound, heat and cure to obtain the flame-retardant epoxy resin compound.

[0034] In the present invention, mixing is preferably carried out in a mixer. In the present invention, the heating and curing temperature and heating and curing time of all raw materials after mixing are the same as the heating and curing temperature and curing time of the epoxy resin in the raw materials. In the present invention, the temperature and time of heat curing vary with the type of epoxy resin. Those skilled in the art can know the heat curing temperature and heat curing time of different epoxy resins on the basis of the prior art. , which will not be repeated here.

[0035] The present invention also provides...

Embodiment 1

[0038] The parts by mass of each component are: 95 parts of glycidyl ester epoxy resin, 0.5 part of black phosphorus, 1 part of curing agent maleic anhydride, 1 part of melamine, 1 part of magnesium hydroxide, 1 part of silicon dioxide, titanium dioxide 0.5 parts, the mass fraction of black phosphorus is 0.5%.

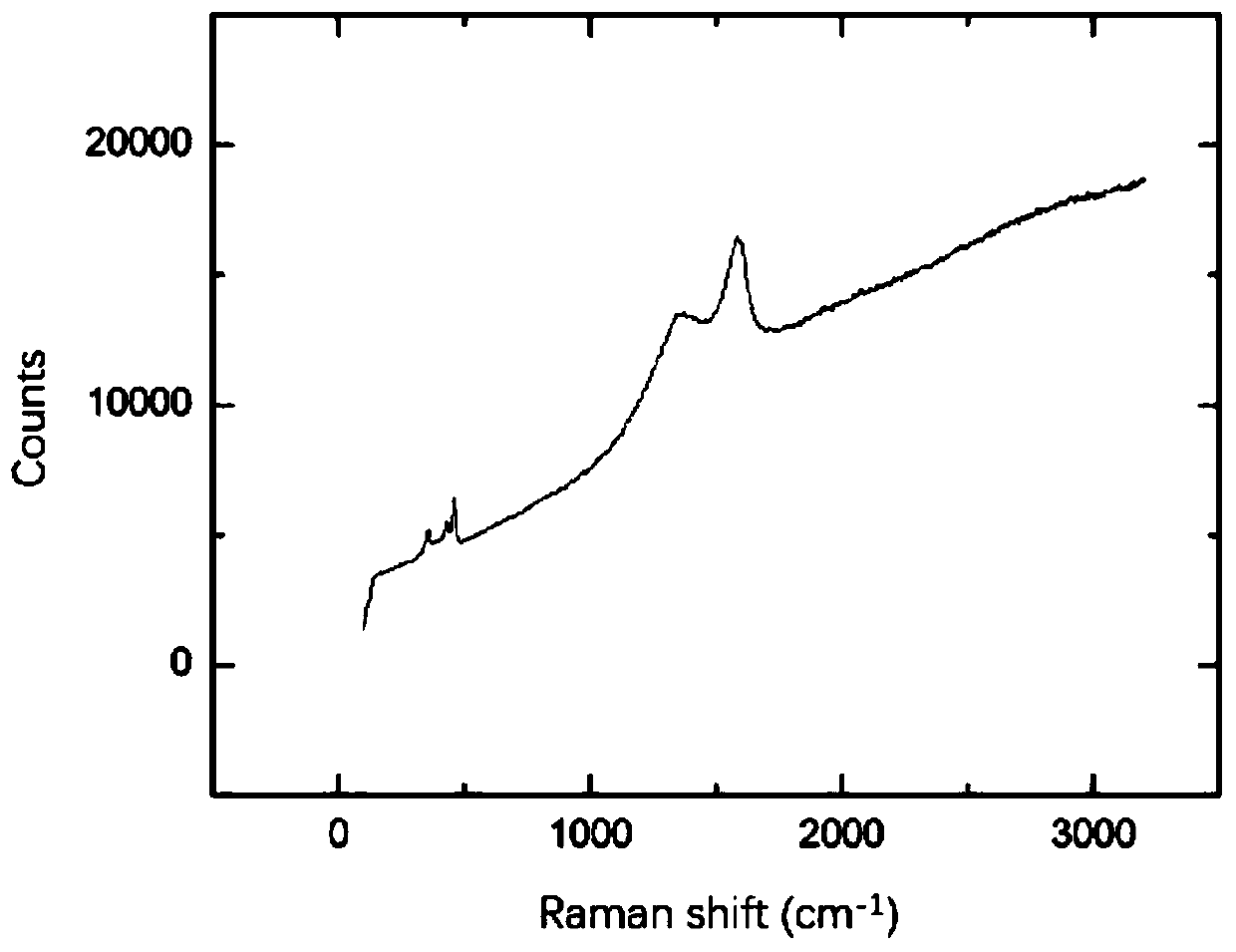

[0039] The Raman spectrum of the flame retardant compound that embodiment 1 obtains is as figure 1 shown by figure 1 It can be known that the flame retardant compound prepared in Example 1 contains peaks corresponding to black phosphorus and epoxy resin.

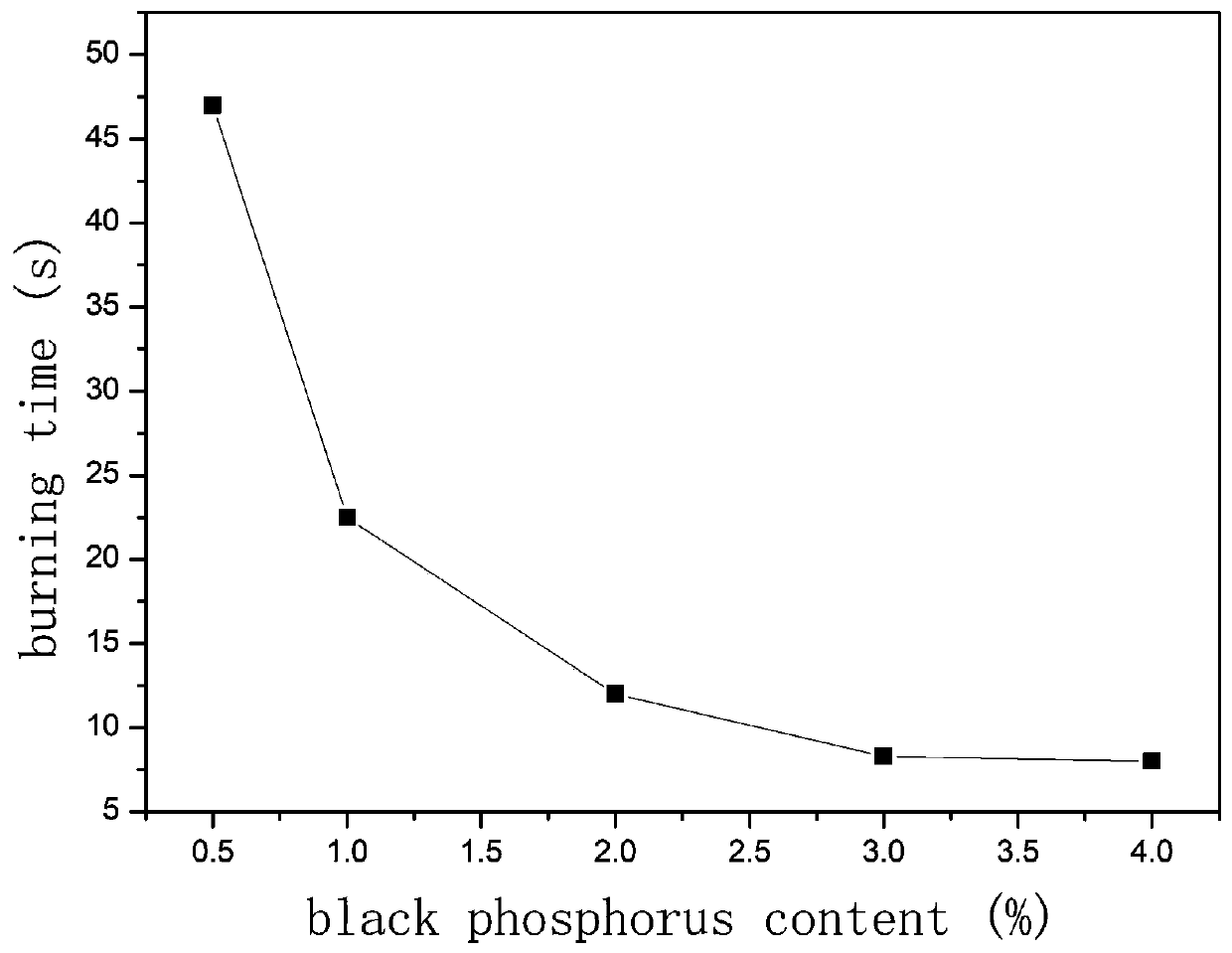

[0040] The flame retardant performance of the flame retardant compound obtained in Example 1 is tested. The test method is: according to the vertical burning test method in UL94 "Equipment and Appliance Component Materials Flammability Test", determine the flame retardant grade of the composite material. Spline size: length 125±5mm, width 13±0.5mm, thickness 1.5±0.2mm. Test with 5 samples, measure the total burnin...

Embodiment 2

[0043] The parts by mass of each component are: 95 parts of glycidyl ether type epoxy resin, 1 part of black phosphorus (ene), 2 parts of ethylenediamine, 2 parts of triphenylphosphorus, and the mass fraction of black phosphorus is 1%.

[0044] Flame retardancy: UL94V-1 level, the average burning time of 5 splines is 23s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com