Polypropylene raw material mixture with fully dispersed red pigment and preparation method thereof

A technology of pigment dispersion and polypropylene, applied in the field of polypropylene production, can solve the problems of difficult dispersion, polypropylene color difference, etc., and achieve the effect of improving dispersibility, reducing the amount of waste silk and good color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

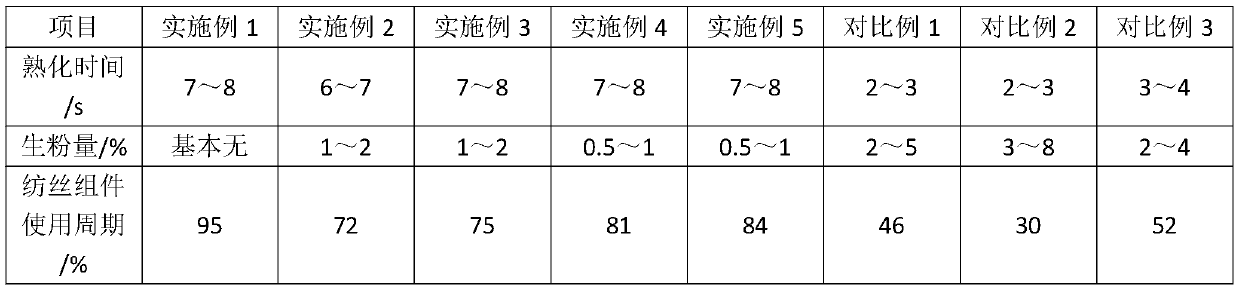

Examples

Embodiment 1

[0028] A polypropylene raw material mixture with fully dispersed red pigment, which is composed of the following components in mass percentage: MFI20 polypropylene powder 49.97%, permanent bright red pigment 27.99%, BASF PE2 polyethylene wax 18.19%, stearic acid Zinc 2.80%, electrostatic agent 0.98%, silicone powder 0.07%.

[0029] The preparation method of the polypropylene raw material mixture that above-mentioned red pigment is fully dispersed comprises the following steps:

[0030] (1) Add each raw material in the mixer in turn, start the mixer, keep the mixer rotating and mixing at low speed, the rotating speed is 200 rpm, and the running time is 5 minutes;

[0031] (2) Then increase the speed of the mixer to 1500 rpm and rotate for 15 minutes to fully mix the materials;

[0032] (3) Reduce the mixer to a low-speed rotation state of 200 rpm and rotate for 7 to 8 seconds to mature the material, and release the material completely to obtain the polypropylene raw material m...

Embodiment 2

[0035] A polypropylene raw material mixture in which the red pigment is fully dispersed, its preparation method is the same as that of Example 1, the difference is that it consists of the following components in mass percentage: 48% of MFI20 polypropylene powder, permanent brilliant red pigment 30%, BASF PE2 Polyethylene Wax 18%, Static Agent 0.95%, Silicone Powder 0.05%, and Zinc Stearate 3%.

Embodiment 3

[0037] A polypropylene raw material mixture in which the red pigment is fully dispersed, its preparation method is the same as that of Example 1, the difference is that it consists of the following components in mass percentage: 49.5% of MFI20 polypropylene powder, permanent brilliant red pigment 28.4%, BASFPE2 polyethylene wax 18.5%, static agent 1%, silicone powder 0.1%, and zinc stearate 2.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com