High strength sprayed concrete for high ground temperature tunnels and preparation method thereof

A technology of shotcrete and high ground temperature, applied in the field of concrete, can solve the problems of low thermal conductivity, high interfacial bond strength, good impermeability, etc., and achieve the effects of uniform hydration of concrete, alleviation of high temperature shedding, and reduced water migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

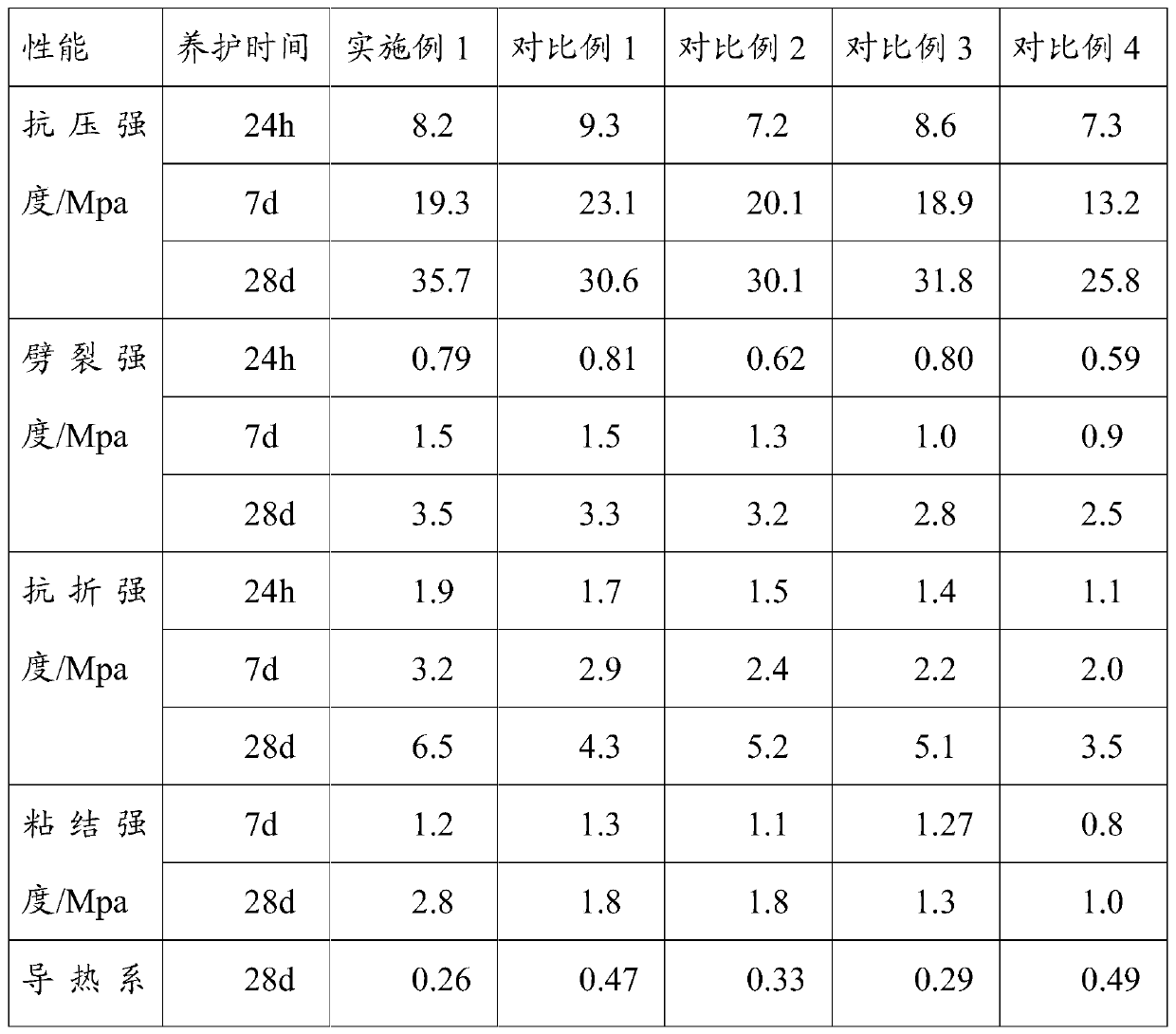

Examples

Embodiment 1

[0033] A method for preparing high-strength shotcrete for tunnels with high ground temperature, the raw material ratio is as follows:

[0034] 1m 3 The quality of raw materials contained are: cement 350kg, fly ash 75kg, slag powder 75kg, gravel 483kg, sand 650kg, water 225kg, vitrified microspheres 100kg, PVA fiber 1kg, steel fiber 40kg, modified rubber 31.5kg, Water agent 4kg, accelerator 25kg.

[0035] The preparation method is implemented according to the following steps:

[0036] Step 1: Add 6kg of sodium silicate into 50L of warm water at a temperature of 40°C to fully dissolve to obtain a sodium silicate sol; then add 94kg of rubber powder to the sodium silicate sol, stir and mix for 2 hours, and let it stand for 2 hours to obtain the modified product rubber;

[0037] Step 2: Stir and mix cement, slag powder, fly ash, sand, coarse aggregate, vitrified beads, water reducing agent and water to obtain a base material; then add modified rubber, steel fiber, and PVA fiber ...

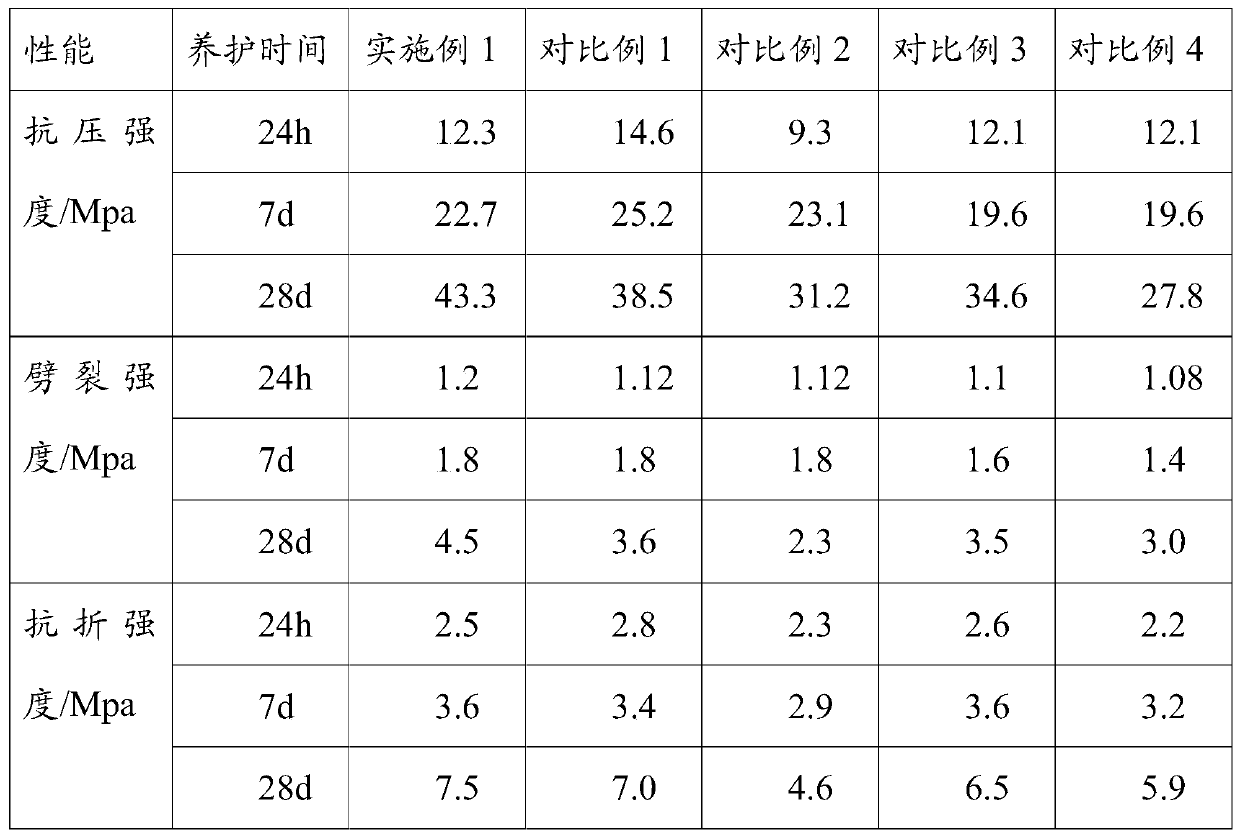

Embodiment 2

[0040] A method for preparing high-strength shotcrete for tunnels with high ground temperature, the raw material ratio is as follows:

[0041] 1m 3 The quality of raw materials contained are: cement 315kg, fly ash 67.5kg, slag powder 67.5kg, gravel 480kg, sand 630kg, water 202.5kg, vitrified microspheres 100kg, PVA fiber 1kg, steel fiber 35kg, modified rubber 30kg , 3.6kg of water reducer, 22.5kg of accelerator.

[0042] The preparation method is implemented according to the following steps:

[0043] Step 1: Add 6kg of sodium silicate into 50L of warm water at a temperature of 40°C to fully dissolve to obtain a sodium silicate sol; then add 94kg of rubber powder to the sodium silicate sol, stir and mix for 2 hours, and let it stand for 2 hours to obtain the modified product rubber;

[0044] Step 2: Stir and mix cement, slag powder, fly ash, sand, coarse aggregate, vitrified beads, water reducing agent and water to obtain base material; then add modified rubber, steel fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com