Modified aluminum oxide, aluminum oxide paste, preparation method of aluminum oxide paste, ceramic coating lithium battery diagram and preparation method of ceramic coating lithium battery diagram

A technology of alumina and alumina powder, which is used in battery pack parts, circuits, electrical components, etc., can solve the complex water removal process of ceramic coated diaphragms, high moisture content of ceramic coated diaphragms, and low moisture content of diaphragms, etc. problems, to achieve long-term stability, not easy to agglomerate and abnormal increase in particle size, and good slurry dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

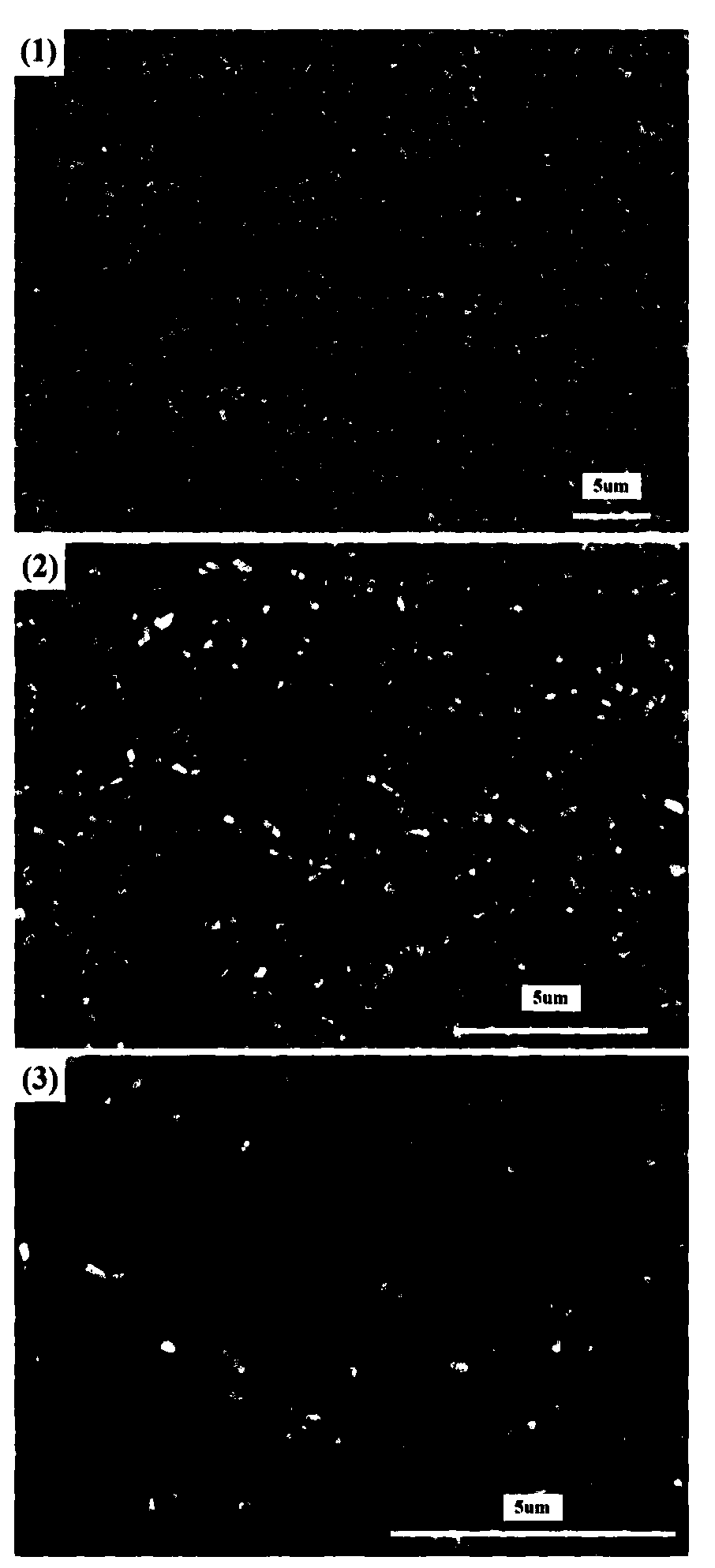

[0120] Add 0.5 parts of AA / AMPS and 99.5 parts of alumina powder into a high-speed mixer for mixing for 1 hour, then dry at 110°C for 2 hours to obtain modified alumina powder I.

preparation example 2

[0122] Add 0.5 parts of TM-613 and 99.5 parts of alumina powder into a high-speed mixer for mixing for 1 hour, then dry at 110°C for 2 hours to obtain modified alumina powder II.

preparation example 3

[0124] Add 0.5 parts of T-225 and 99.5 parts of alumina powder into a high-speed mixer for mixing for 1 hour, then dry at 110°C for 2 hours to obtain modified alumina powder III.

PUM

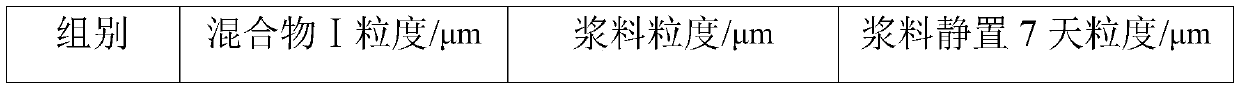

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com