High-crystallinity submicron nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

A sub-micron, cathode material technology, used in electrical components, battery electrodes, structural parts, etc., can solve the problems of increasing the transport distance of lithium ions and electrons, decreasing cycle stability, and easily broken secondary particles. Improve compaction density and cycle stability, improve cycle stability, and reduce the effect of cation mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

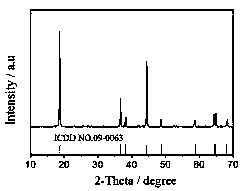

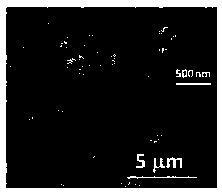

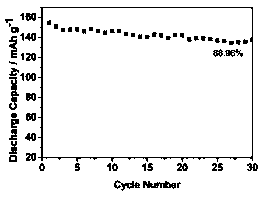

[0039] Example 1. A highly crystalline submicron nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof, comprising the following steps:

[0040] (1) The total molar concentration of nickel, cobalt and manganese metal elements is a mixed salt solution of 1mol / L nickel, cobalt and manganese, a mixed alkaline solution of 1mol / L sodium carbonate and 0.2mol / L ammonia water, and added to the bottom solution as In 25ml of ethanol aqueous solution, control the pH value of the bottom liquid solution to 7, heat and stir at 1200r / min at a temperature of 45°C for 10h to form a suspension, filter, take the solid, wash 4 times, and dry at a temperature of 105 In the blast drying oven at ℃, dry for 12h to obtain a ternary precursor; the mixed salt solution of nickel, cobalt and manganese is sulfate, and the moles of Ni, Co and Mn elements in the mixed salt solution of nickel, cobalt and manganese Ratio is 5:2:3, ethanol solution is used as bottom liqui...

Embodiment 2

[0042] Example 2. A highly crystalline submicron nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof, comprising the following steps:

[0043] (1) The total molar concentration of nickel, cobalt and manganese metal elements is a mixed salt solution of 1mol / L nickel, cobalt and manganese, a mixed alkaline solution of 1mol / L sodium carbonate and 0.2mol / L ammonia water, and added to the bottom solution as In 25ml of ethanol aqueous solution, control the pH value of the bottom liquid solution to 8, heat and stir at 1200r / min at a temperature of 45°C for 10h to form a suspension, filter, take the solid, wash 4 times, and dry at a temperature of 105 In the blast drying oven at ℃, dry for 12h to obtain a ternary precursor; the mixed salt solution of nickel, cobalt and manganese is sulfate, and the moles of Ni, Co and Mn elements in the mixed salt solution of nickel, cobalt and manganese Ratio is 5:2:3, ethanol solution is used as bottom liqui...

Embodiment 3

[0045] Example 3. A highly crystalline submicron nickel-cobalt-manganese ternary positive electrode material and a preparation method thereof, comprising the following steps:

[0046] (1) The total molar concentration of nickel, cobalt and manganese metal elements is the mixed alkaline solution of 1mol / L nickel, cobalt and manganese salt solution, 1mol / L sodium carbonate and 0.2mol / L ammonia water, which is added to the bottom solution. In 25ml of ethanol aqueous solution, control the pH value of the bottom liquid solution to 10, heat and stir at 1200r / min at a temperature of 45°C for 10h to form a suspension, filter, take the solid, wash 4 times, and dry at a temperature of 105 In the blast drying oven at ℃, dry for 12h to obtain a ternary precursor; the mixed salt solution of nickel, cobalt and manganese is a chloride salt, and the mixed salt solution of nickel, cobalt and manganese contains elements of Ni, Co and Mn The molar ratio is 5:2:3, the ethanol solution is used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com