Multilayer protective coating with high-temperature steam oxidation resistance and hot water corrosion resistance and preparation method and application

A protective coating and water vapor technology, applied in the coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of poor hot water corrosion resistance, loss of accident tolerance, coating corrosion, etc. To prevent diffusion, overcome the inability to resist hot water corrosion, and improve the toughness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] All examples were prepared as figure 2 As shown, when the background vacuum is ≤8×10 -5 Pa, start to heat sample 7 to 600°C and keep it warm for 2 hours, apply a bias voltage of -15V ~ -10V to the substrate, and enter Ar and N respectively through the gas inlet 6 in the chamber 1 2 As a sputtering and reaction gas source, the air pressure of the chamber 1 is adjusted by controlling the opening and closing of the gas outlet 5. In this gas source, 3A targets (Cr a Al b Si 1-a-b target, wherein, 0.5≤a≤0.6, 0.25≤b≤0.3) and 3B target (Cr target) get multi-layer protective coating, 3A target and 3B target are separated by separator 4 (the purpose of isolation is 3A target and 3 B target work independently without interfering with each other, so that the Cr layer and the CrAlSiN layer do not interfere with each other when depositing the Cr layer and the CrAlSiN layer). In the process of sputtering the 3A target and the 3B target, the RF-assisted DC power supply method is u...

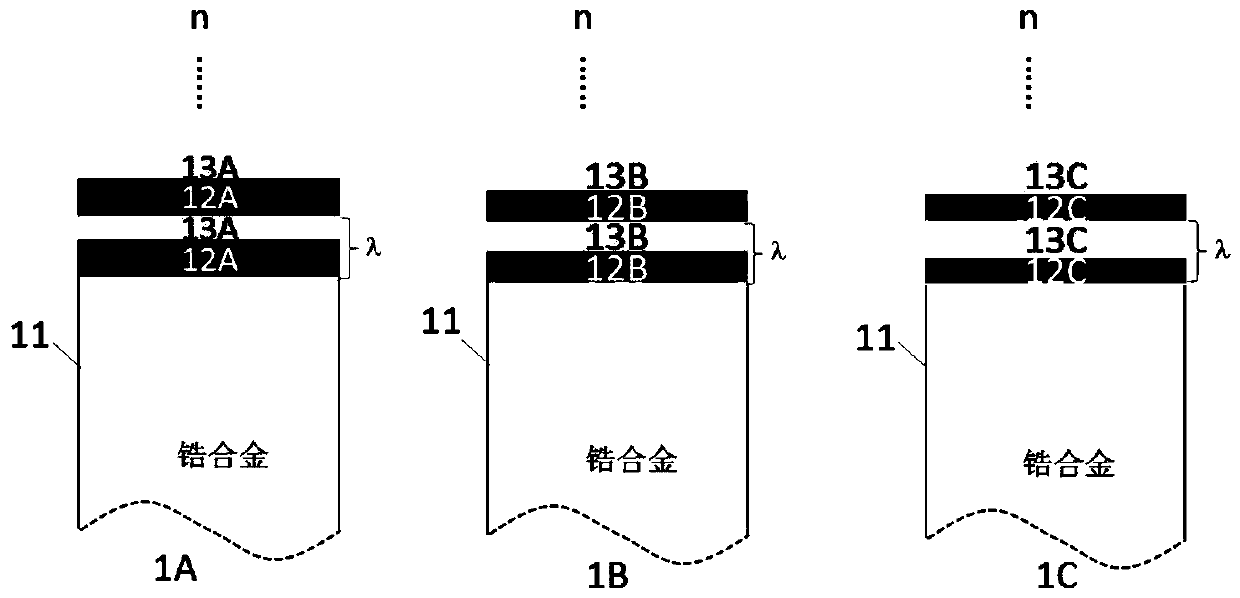

Embodiment 1

[0064] This embodiment is prepared by magnetron sputtering method, and the parameters are set as: background vacuum 8×10 -5 Pa; chamber air pressure: 0.5Pa; 3A target components use Cr 0.6 Al 0.3 Si 0.1 target, 3A target power density is 6.2 W / cm 2 ; 3B target power density is 5.2W / cm 2 ; Sputter the 3A target first (the 3B target is closed at this time), and pass in N 2 The flow ratio of Ar gas and Ar gas is 0.13, and the control sample 7 is facing the 3A target, and a 6 μm thick CrAlSiN layer is obtained by sputtering; after that, the 3A target and the N 2 Gas source, start 3B target, start sputtering 3B target and control sample 7 to face 3B target, sputter to get a 4μm thick Cr layer, and do this alternately once to get a Cr / CrAlSiN multilayer protective coating with a periodic layer λ of 1 , one of the periodic layers has a CrAlSiN layer thickness of 6 μm and a Cr layer thickness of 4 μm.

[0065] Structural characterization of the Cr / CrAlSiN (λ=1) multilayer protec...

Embodiment 2

[0071] This embodiment is prepared by magnetron sputtering method, and the parameters are set as: background vacuum 6×10 -5 Pa; chamber air pressure: 0.5Pa; 3A target components use Cr 0.5 Al 0.25 Si 0.25 ; 3A target power density is 6.7 W / cm 2 , 3B target power density is 4.8W / cm 2 ; Sputter the 3A target first (the 3B target is closed at this time), and pass in N 2 The flow ratio of Ar gas and Ar gas is 0.15, and the control sample 7 is facing the 3A target, and a 2.5 μm thick CrAlSiN layer is obtained by sputtering; after that, the 3A target and the N 2 Gas source, start 3B target, start sputtering 3B target and control sample 7 to face 3B target, sputter to get a 2.5μm thick Cr layer, do this twice alternately, get a Cr / CrAlSiN multilayer protective coating with a periodic layer λ of 2 Layers, one of the periodic layers has a CrAlSiN layer thickness of 2.5 μm and a Cr layer thickness of 2.5 μm.

[0072] Structural characterization of the Cr / CrAlSiN (λ=2) multilayer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com