Nano spherical carbon-based solid acid taking lignin as raw material as well as preparation method and application thereof

A carbon-based solid acid and nanosphere technology, applied in the field of nano-carbon materials, can solve the problems of low surface area, hindering the activity of carbon-based solid acid, and low porosity, and achieve high carbon content, easy separation, and low equipment corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

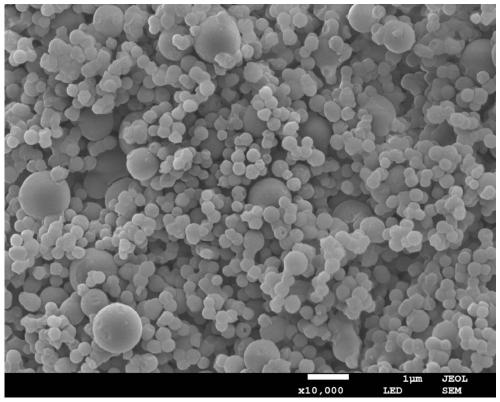

Embodiment 1

[0029] Weigh 0.1g of industrial lignin and place it in a 250ml beaker, add 20ml of acetone to obtain a 5mg / ml lignin in acetone solution. 80ml of deionized water was slowly added dropwise therein and stirred continuously at normal temperature and pressure to obtain a lignin nanomicelle solution. Then freeze-dry the lignin micellar solution to obtain lignin nanosphere powder. Disperse 0.1g of lignin nanosphere powder in 3ml of deionized water, put it into a polytetrafluoroethylene tank, put it in an oil bath for hydrothermal carbonization at 260°C for 10h, and suction filter the carbonized product. After washing with deionized water and drying, lignin carbon nanospheres are obtained. Mix 0.1g lignin nanocarbon spheres and 2ml concentrated sulfuric acid in a polytetrafluoroethylene tank, carry out sulfonation at 150°C for 6h, filter the black liquid after sulfonation, and wash the black liquid repeatedly with boiled deionized water product until the filtrate is neutral. That ...

Embodiment 2

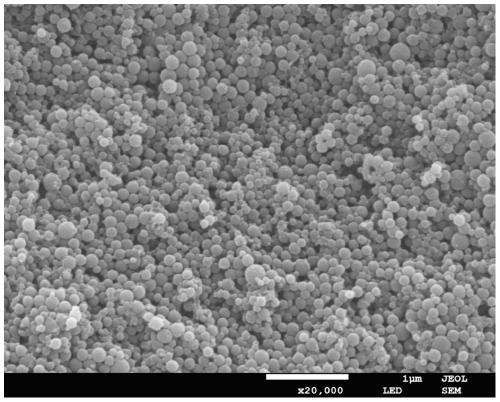

[0032] Weigh 1 g of alkali lignin into a 25 ml flask, and then add 5 ml of acetic anhydride to obtain a lignin acetic anhydride solution. Put the flask into a water bath and heat it at a temperature of 90°C for 2 hours. After the reaction is completed, the solution is suction-filtered, washed with deionized water, and dried to obtain acetylated lignin. 0.1 g of acetylated lignin was weighed and placed in a 250 ml beaker, and 20 ml of tetrahydrofuran was added to obtain a 5 mg / ml lignin tetrahydrofuran solution. 80ml of deionized water was slowly added dropwise therein and stirred continuously at normal temperature and pressure to obtain a lignin nanomicelle solution. Then freeze-dry the lignin micellar solution to obtain lignin nanosphere powder. Disperse 0.1g of lignin nanosphere powder in 3ml of deionized water and put it into a polytetrafluoroethylene tank, put it in an oil bath for hydrothermal carbonization at 240°C for 10h, and suction filter the carbonized product to ...

Embodiment 3

[0034] Add 1g of alkali lignin into a 25ml round bottom flask, then add 5ml of acetyl chloride and 10ml of glacial acetic acid, heat the flask in a water bath at 40°C for 2h, after the reaction is over, filter the solution with suction, wash with deionized water, and dry , to obtain acetylated lignin. 0.1 g of acetylated lignin was weighed and placed in a 250 ml beaker, and 20 ml of dimethylamide was added to obtain a 5 mg / ml lignin dimethylamide solution. 80ml of deionized water was slowly added dropwise therein and stirred continuously at normal temperature and pressure to obtain a lignin nanomicelle solution. Then freeze-dry the lignin micellar solution to obtain lignin nanosphere powder. Disperse 0.1g of lignin nanosphere powder in 3ml of deionized water and put it into a polytetrafluoroethylene tank, put it in an oil bath for hydrothermal carbonization at 240°C for 10h, and suction filter the carbonized product to remove After washing with ion water and drying, lignin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com