Capillary pipe air resistance measurement device and measurement method

A measuring device and capillary technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as low precision and difficulty in measuring air resistance of woolen pipelines, and achieve guaranteed accuracy and measurement speed Fast, high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

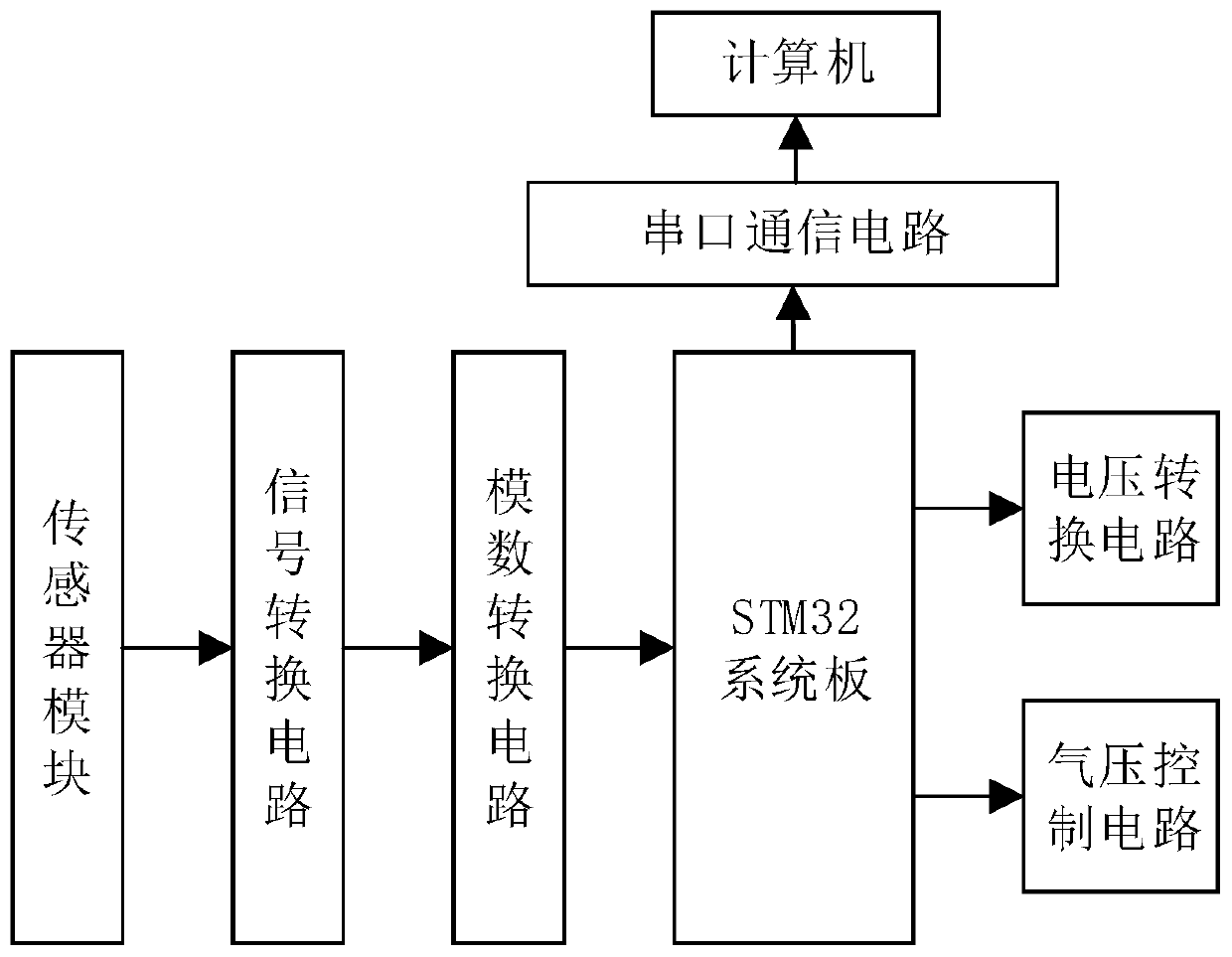

[0028] Such as figure 1 As shown, the device of the present invention is divided into four modules, including a two-stage series closed-loop stabilized pressure gas source 1 , a measurement module 2 , a hardware control system 4 and a computer 3 . The measurement module 2 and the computer 3 are placed on the optical platform 5, and the two-stage series closed-loop stabilized pressure gas source 1 is connected to the measurement pipeline 2 through the gas pipe.

[0029] Such as figure 2 As shown, the measurement pipeline includes an air filter valve 6, an oil mist separator 7, an electrical proportional valve 8, an initial capillary pipeline 9, an inlet temperature sensor 10, an inlet connector 11, an inlet pressure sensor 12, and a measured capillary pipeline 13 , Single ear stepless clamp 14, measured capillary pipeline 15, outlet connector 16, outlet pressure sensor 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com