Ultra-black carbon-silica core-shell structure aerogel and preparation method thereof

A technology of silica and core-shell structure, applied in the preparation/purification of silica, silicon oxide, carbon, etc., can solve the problems of damage to the circuit system of the instrument, danger, etc., and achieve short process flow, short production cycle, and guaranteed Effect of cladding mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

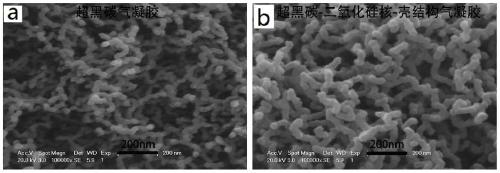

[0040] This embodiment is an ultra-black carbon-silica core-shell structure airgel, the electrical conductivity of which is adjustable, and its preparation method is:

[0041]Dissolve 3.235g of resorcinol in 91.26mL of deionized water, then add 4.47mL of formaldehyde solution and fully stir; finally add 0.74mL of sodium carbonate aqueous solution with a concentration of 0.05mol / L, and fully stir for 2 hours to obtain resorcinol- Formaldehyde sol. Transfer the obtained resorcinol-formaldehyde sol into a glass bottle and seal it for storage, and store the glass bottle in an incubator at 85°C for 3 days to gel the resorcinol-formaldehyde sol to obtain resorcinol - Formaldehyde wet gel. The obtained wet gel was placed in absolute ethanol for sufficient solvent replacement, and then subjected to supercritical carbon dioxide drying to obtain resorcinol-formaldehyde airgel. The obtained resorcinol-formaldehyde airgel was placed in a tube furnace under the protection of a nitrogen a...

Embodiment 2

[0046] This embodiment is an ultra-black carbon-silica core-shell structure airgel, the electrical conductivity of which is adjustable, and its preparation method is:

[0047] Dissolve 3.235g of resorcinol in 91.26mL of deionized water, then add 4.47mL of formaldehyde solution and fully stir; finally add 0.74mL of sodium carbonate aqueous solution with a concentration of 0.05mol / L, and fully stir for 2 hours to obtain resorcinol- Formaldehyde sol. Transfer the obtained resorcinol-formaldehyde sol into a glass bottle and seal it for storage, and store the glass bottle in an incubator at 85°C for 3 days to gel the resorcinol-formaldehyde sol to obtain resorcinol - Formaldehyde wet gel. The obtained wet gel was placed in absolute ethanol for sufficient solvent replacement, and then subjected to supercritical carbon dioxide drying to obtain resorcinol-formaldehyde airgel. The obtained resorcinol-formaldehyde airgel was placed in a tube furnace under the protection of a nitrogen ...

Embodiment 3

[0050] This embodiment is an ultra-black carbon-silica core-shell structure airgel, the electrical conductivity of which is adjustable, and its preparation method is:

[0051] Dissolve 3.235g of resorcinol in 91.21mL of deionized water, then add 4.47mL of formaldehyde solution and stir thoroughly; finally add 1.18mL of sodium carbonate aqueous solution with a concentration of 0.05mol / L, and fully stir for 2 hours to obtain resorcinol- Formaldehyde sol. Transfer the obtained resorcinol-formaldehyde sol into a glass bottle and seal it for storage, and store the glass bottle in an incubator at 85°C for 3 days to gel the resorcinol-formaldehyde sol to obtain resorcinol - Formaldehyde wet gel. The obtained wet gel was placed in absolute ethanol for sufficient solvent replacement, and then subjected to supercritical carbon dioxide drying to obtain resorcinol-formaldehyde airgel. The obtained resorcinol-formaldehyde airgel was placed in a tube furnace under the protection of a nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com