Cutting sheet, cutting sheet processing mold and processing method

A technology for processing molds and cutting blades, which is applied in the field of sintering machine molds and diamond saw blades, can solve the problems of harming workers' health, not very strict material distribution, and low efficiency of manual material distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

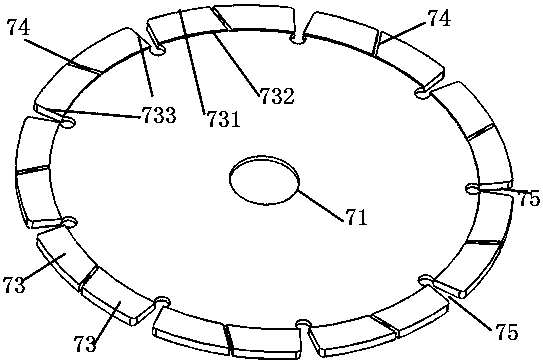

[0131] The applicant explained the structure, working principle and sintering process of the cutting sheet processing mold with reference to the accompanying drawings.

[0132] In the accompanying drawings, 1 is the bottom mold, 2 is the lower hydraulic press, 3 is the pull rod, 4 is the middle mold, 5 is the upper hydraulic press, 6 is the top mold, 7 is the bottom sheet, 8 is the forming mold, 91 is the fixed positioning rod, 92 Is the movable positioning rod, 10 is the latch, 101 is the insertion rod, 21 is the screw of the lower hydraulic machine, 211 is the hole of the screw of the lower hydraulic machine, 22 is the lower hydraulic machine base, 221 is the limit of the lower hydraulic machine base, 23 is the gasket of the lower hydraulic machine, 24 is The lower hydraulic column, 241 is the column body, 242 is the pressing tooth, 2421 is the inner arc of the pressing tooth, 2422 is the outer arc of the pressing tooth, 243 is the concave part of the lower hydraulic column, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com