Modular structure wall body of high-temperature heating furnace and mounting method

A high-temperature heating and modular structure technology, which is applied to lighting and heating equipment, furnaces, furnace linings, etc., can solve problems such as hindering production operations, delaying the normal production of the furnace, and increasing the area occupied by the furnace, so as to reduce heat dissipation and maintenance costs, reduce The effect of reducing the area occupied by the furnace and the cooling time of the furnace shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

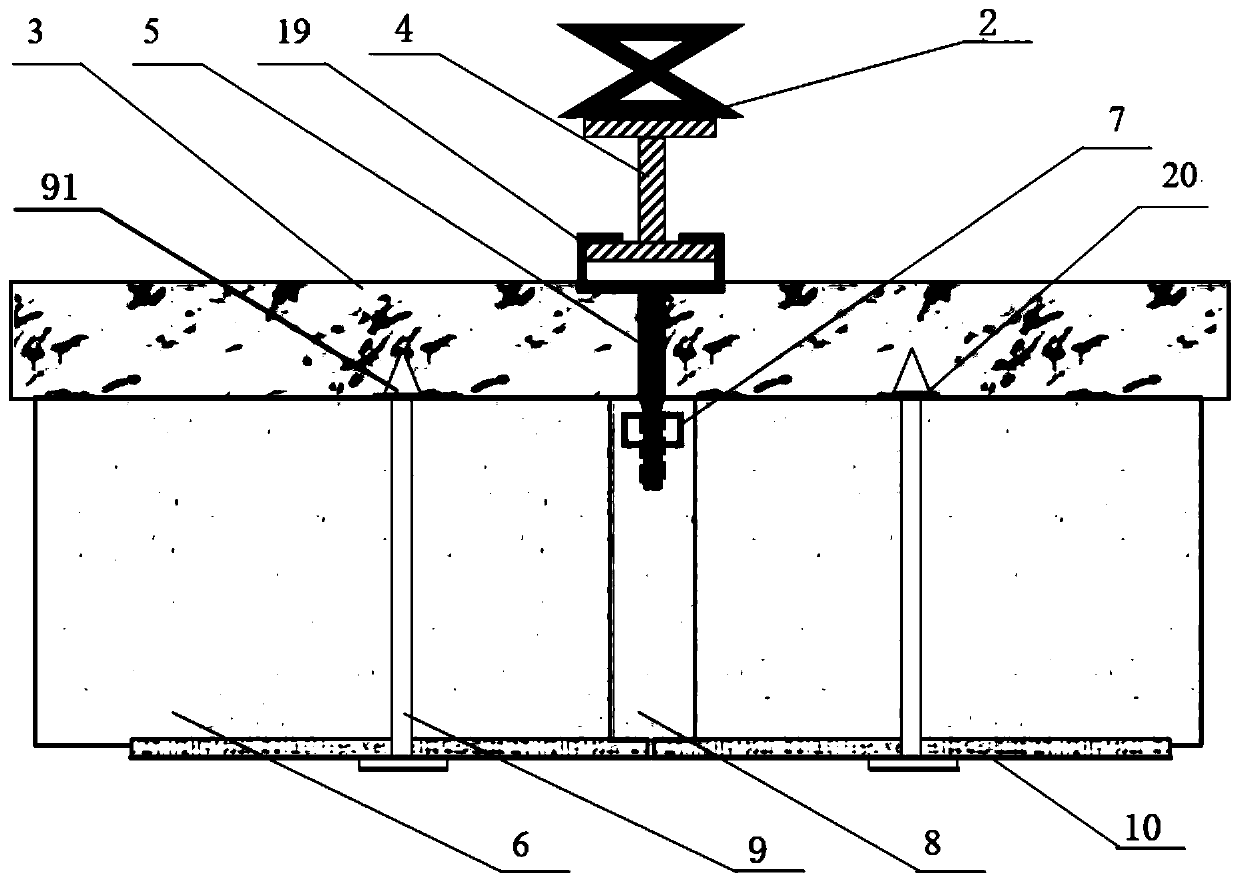

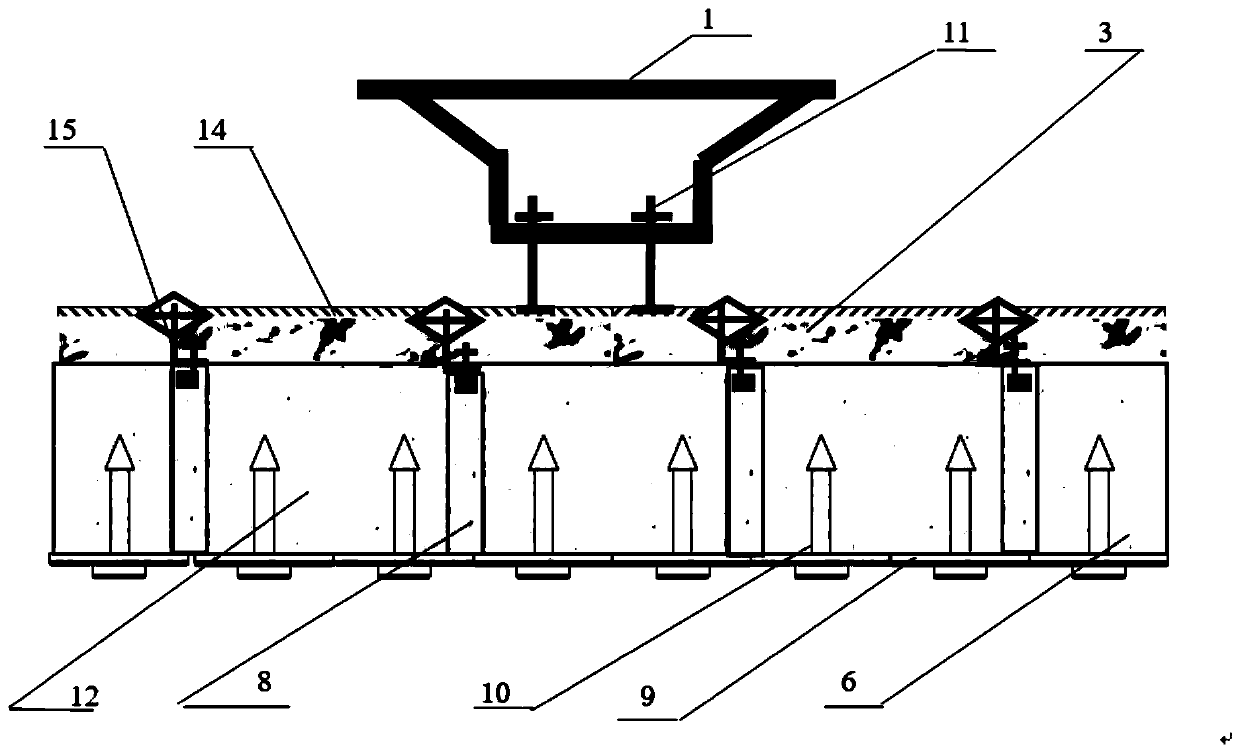

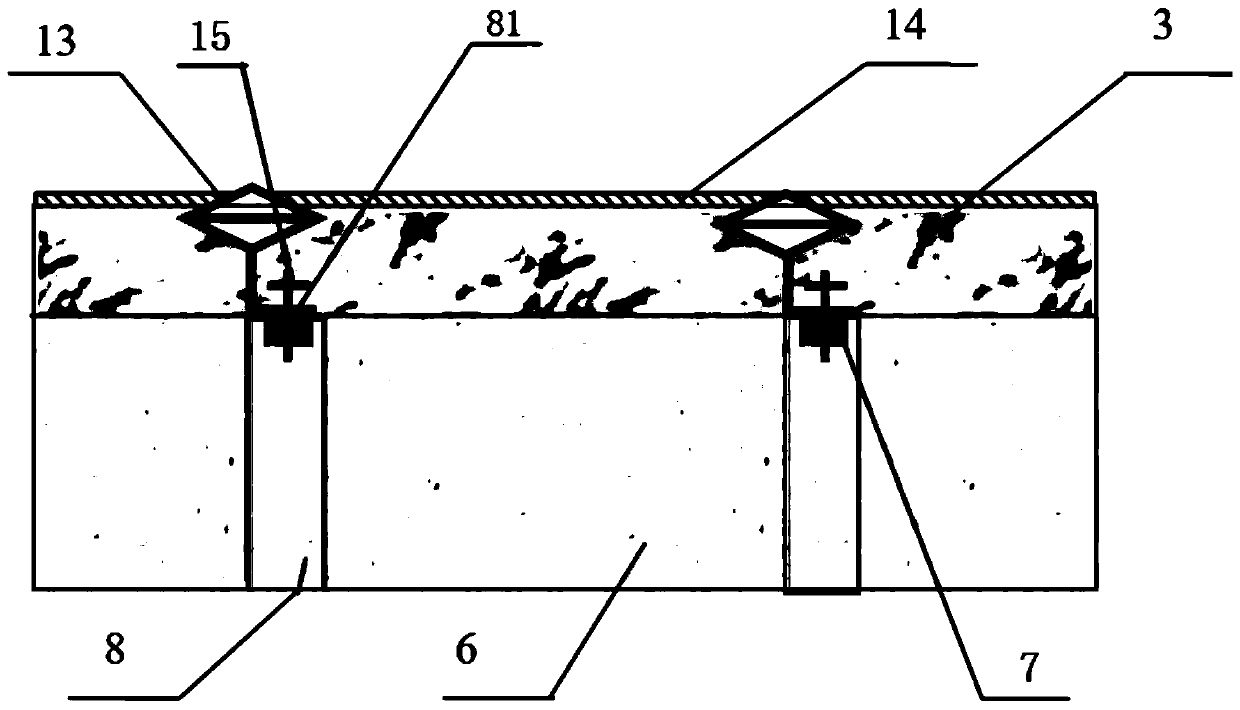

[0045] A modular structure wall for high temperature heating furnace, see Figure 1-Figure 5 , which includes preset furnace wall main trusses 1 and furnace roof trusses 2, the bottom surfaces of the furnace roof trusses 2 are respectively fixed with corresponding connecting I-beams 4, and the bottom of the connecting I-beams 4 is articulated with The top clamping structure of the hoisting outer screw rod 5,

[0046] The upper surface of the ceramic fiber cotton module 6 is evenly distributed with upward lifting external screw rods 5, and the ceramic fiber cotton module 6 is installed on the lower surface of the furnace roof truss 2 through the lifting external screw rod 5, and is connected to the There is a gap on the lower surface of the I-beam 4, and the ceramic fiber cotton felt 3 is laid in the gap area between the ceramic fiber cotton module 6 and the lower surface connecting the I-beam 4, and the ceramic fiber surface module 6 The inner lining of the furnace wall is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com