A kind of preparation method of vanadium oxide film

A vanadium oxide thin film and seed layer technology, which is applied in gaseous chemical plating, vacuum evaporation plating, coating, etc., can solve the problem of poor uniformity of vanadium oxide thin film sheet resistance, unfavorable product quality consistency, and poor film uniformity, etc. problems, to achieve high practical value, suitable for large-scale production, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

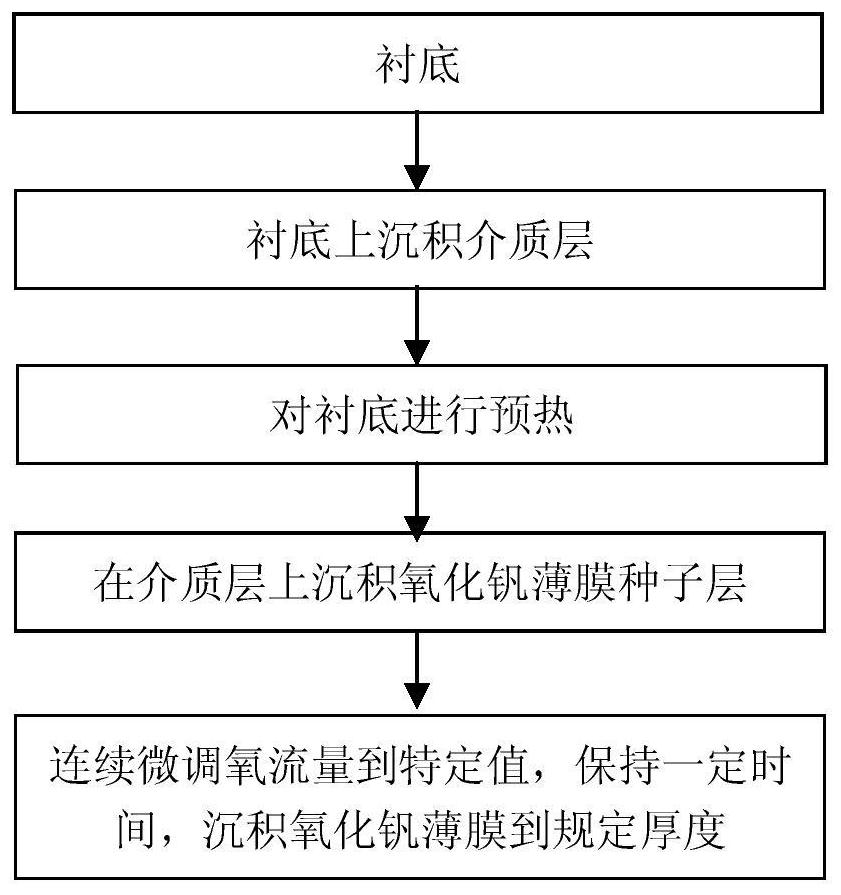

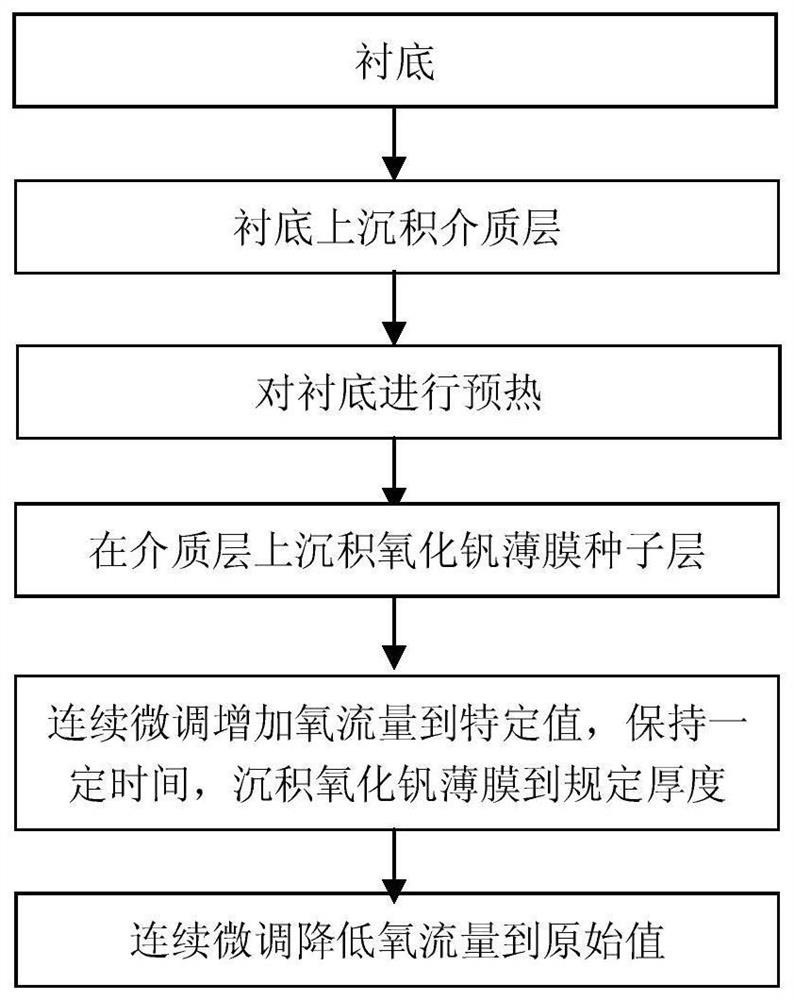

[0030] figure 1 A flow diagram of fabricating a microelectrode structure according to a disclosed embodiment of the present invention is shown.

[0031] In this embodiment, the preparation method of vanadium oxide thin film comprises:

[0032]S101, providing a substrate. In this embodiment, the substrate can be various forms of substrates, including but not limited to semiconductor material substrates (such as bulk Si substrates), compound semiconductor substrates (such as SiC substrates), alloy semiconductor substrates (such as SiGe substrate), etc. In some embodiments, the semiconductor substrate may include a doped epitaxial layer.

[0033] S102, forming a dielectric layer on the substrate. A dielectric layer is deposited on the above substrate. In some embodiments, the dielectric layer includes any one or a combination of insulating materials among silicon nitride, silicon dioxide, and silicon carbide, and mainly functions as an insulating layer. In some embodiments, ...

Embodiment 2

[0038] S101, providing a substrate. In this embodiment, the substrate may be in various forms, and in this embodiment, the substrate is preferably a Si substrate.

[0039] S102, forming a dielectric layer on the substrate. A dielectric layer is deposited on the above substrate. In this embodiment, the dielectric layer is preferably silicon nitride as the dielectric layer (that is, the insulating layer), which mainly plays an insulating role. In this embodiment, the dielectric layer is mainly formed by chemical vapor deposition technology; the specific process conditions of chemical vapor deposition are as follows: deposition temperature 250°C, RF power 400W, SiH4: 300sccm, N2: 4000sccm, NH3: 100sccm, pressure: 5Torr_ .

[0040] S103, preheating the substrate. The preheating temperature for preheating the substrate is preferably 200° C., and the preheating time is preferably 5 minutes.

[0041] S104, using the magnetron sputtering method to form a vanadium oxide thin film s...

Embodiment 3

[0044] S101, providing a substrate. In this embodiment, the substrate may be in various forms, and in this embodiment, the substrate is preferably a silicon substrate.

[0045] S102, forming a dielectric layer on the substrate. A dielectric layer is deposited on the above substrate. In this embodiment, the dielectric layer is preferably silicon dioxide as the dielectric layer (that is, the insulating layer), which mainly plays an insulating role. In this embodiment, the dielectric layer is mainly formed by chemical vapor deposition technology; the specific process conditions of chemical vapor deposition are as follows: deposition temperature 250° C., RF power 400 W, SiH4: 35 sccm, N2O: 1200 sccm, pressure: 2.7 Torr_.

[0046] S103, preheating the substrate. The preheating temperature for preheating the substrate is preferably 150° C., and the preheating time is preferably 5 minutes.

[0047] S104. Using the magnetron sputtering method, a vanadium oxide thin film seed layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com