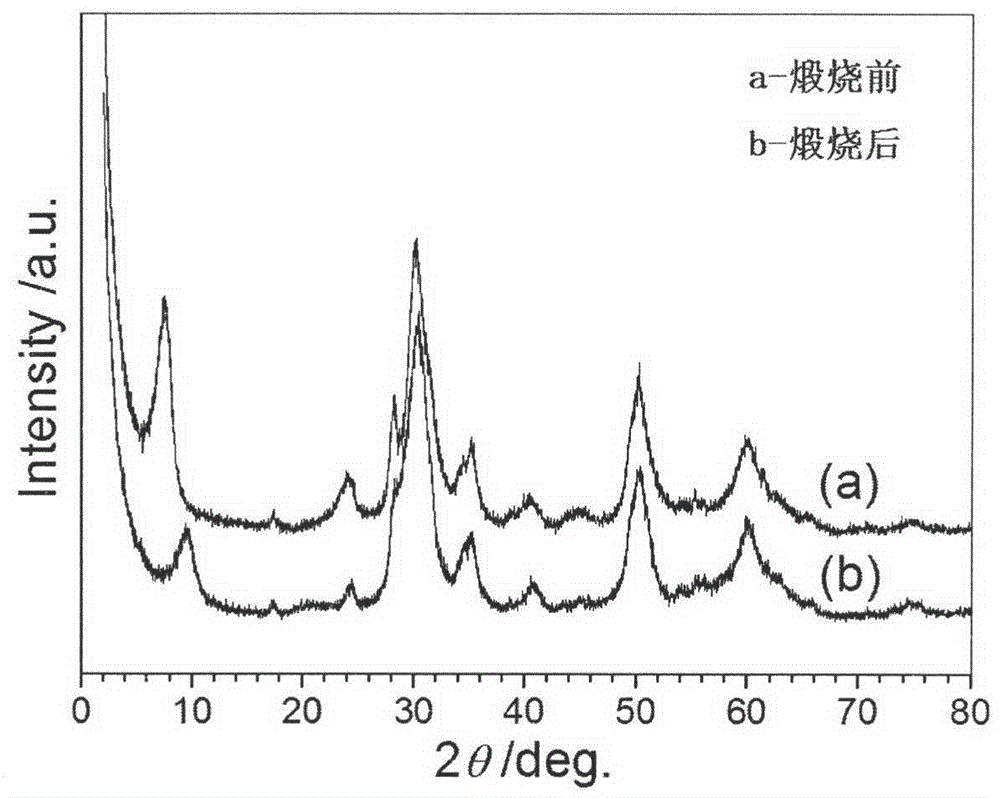

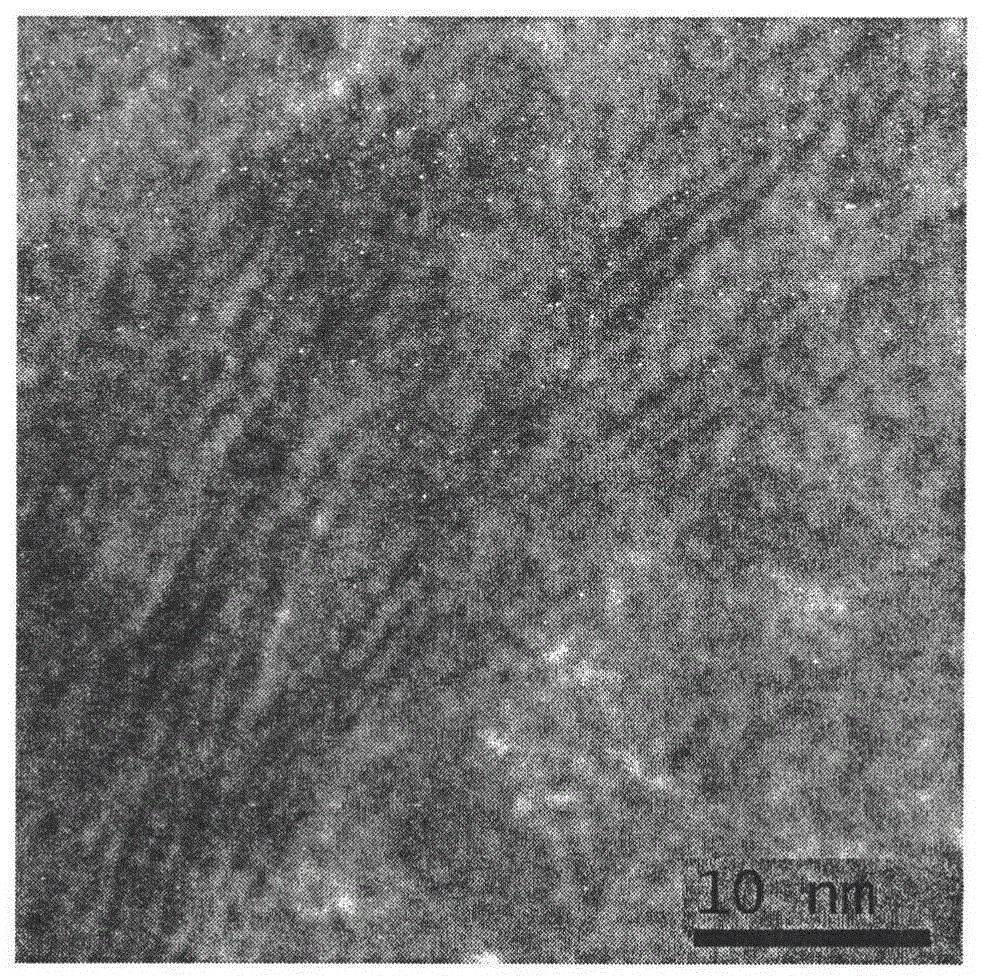

A method for synthesizing ordered layered nano-zirconia polycrystalline powder with tetrahydrofuran as template

A tetrahydrofuran, polycrystalline powder technology, applied in zirconia, nanotechnology, nanotechnology and other directions, can solve the problems of poor thermal stability, disordered nanocrystal arrangement, etc., and achieve the effect of reducing production cost and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve 0.005mol zirconium oxychloride in a flask filled with 25ml of water, then add 25ml of THF in the flask to prepare zirconium oxychloride-tetrahydrofuran-water mixed solution for use;

[0026] (2) Dissolve 0.72g of sodium hydroxide in a flask filled with 25ml of water, then add 25ml of tetrahydrofuran to prepare a sodium hydroxide-tetrahydrofuran-water mixture for use;

[0027] (3) under stirring conditions, the mixed solution prepared in the step (2) is added in the flask in the step (1), the temperature is raised, and the reaction is refluxed for 2 hours;

[0028] (4) Then the mixture obtained in the step (3) is moved to the inner sleeve polytetrafluoroethylene container of the reactor, sealed, the reactor is put into an oven, the temperature is raised to 160° C., and the mixed solvent is thermally reacted for 12 hours under autogenous pressure. Hour;

[0029] (5) Standing at room temperature for 1 day, then washing with water for 3 times, and then centrif...

Embodiment 2

[0034] The reflux reaction time in the step (3) among the embodiment 1 is set as 1 hour. Other steps are with embodiment 1. Obtain product with embodiment 1.

Embodiment 3

[0036] The temperature in step (4) in embodiment 1 is adjusted to 140 ℃, and other steps are the same as embodiment 1. The product obtained is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com