Epoxy adhesive and application thereof

An epoxy adhesive, epoxy resin technology, applied in the direction of adhesive, epoxy resin glue, novolac epoxy resin adhesive, etc., can solve the problem of high etching solution processing cost, large pollution, and reduced product performance and service life and other problems, to achieve the effect of improving product stability and production efficiency, reducing production costs, and stabilizing peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

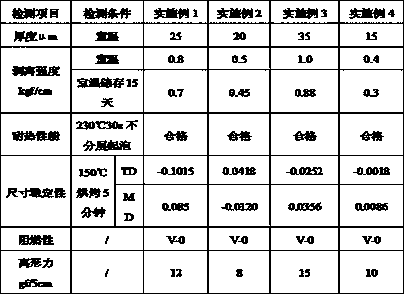

Examples

Embodiment 1

[0021] An epoxy adhesive made from:

[0022] 10 parts of polyester carboxyl-containing polyurethane, 10 parts of hydroxyl-terminated polyphenylene ether, 70 parts of phenolic novolac epoxy resin, 20 parts of bisphenol A novolac epoxy resin, 10 parts of phosphorus-containing epoxy resin, phosphate oligomer 15 parts, 20 parts silicon dioxide, 30 parts magnesium oxide, 3 parts dicyandiamide, 42 parts methyl ethyl ketone.

[0023] The preparation method is as follows:

[0024] Step 1: Mix 10 parts of polyester-type carboxyl-containing polyurethane, 10 parts of hydroxyl-terminated polyphenylene ether, 70 parts of phenol-type novolac epoxy resin, 20 parts of bisphenol A-type novolac epoxy resin, and 10 parts of phosphorus-containing epoxy resin. Put 10 parts of ketone in a high-dispersion mixing tank and stir for 2 hours;

[0025] Step 2: Mix and stir the mixture obtained in Step 1 with 15 parts of phosphate oligomer, 20 parts of silicon dioxide, 30 parts of magnesium oxide and 30...

Embodiment 2

[0034] An epoxy adhesive made from:

[0035] Polyether-type carboxyl-containing polyurethane 25 parts, epoxy-terminated polyphenylene ether 5 parts, bisphenol A novolac epoxy resin 50 parts, phosphorus-containing epoxy resin 30 parts, phosphate ester oligomer 5 parts, aluminum hydroxide 60 parts parts, magnesium oxide 20 parts, phthalic anhydride 10 parts, butanone 43 parts.

[0036] The preparation method is as follows:

[0037] Step 1: Put 25 parts of polyether-type carboxyl-containing polyurethane, 5 parts of epoxy-terminated polyphenylene ether, 50 parts of bisphenol A novolac epoxy resin, 30 parts of phosphorus-containing epoxy resin, and 8 parts of methyl ethyl ketone in a high dispersion Stir in the mixing tank for 1h;

[0038] Step 2: Mix and stir the mixture obtained in Step 1 with 5 parts of phosphate oligomer, 60 parts of aluminum hydroxide, 20 parts of magnesium oxide and 30 parts of butanone for 3 hours;

[0039] Step 3: Mix and stir the mixture obtained in Ste...

Embodiment 3

[0047] An epoxy adhesive made from:

[0048] 20 parts of polyester carboxyl-containing polyurethane, 20 parts of polyether carboxyl-containing polyurethane, 15 parts of hydroxyl-terminated polyphenylene ether, 75 parts of biphenyl epoxy resin, 45 parts of phosphorus-containing epoxy resin, and 5 parts of phosphate oligomer , 50 parts of silicon dioxide, 50 parts of aluminum hydroxide, 3.6 parts of diethylenetriamine, 1.8 parts of m-phenylenediamine, and 42 parts of butanone.

[0049] The preparation method is as follows:

[0050] Step 1: Mix 20 parts of polyester-type carboxyl-containing polyurethane, 20 parts of polyether-type carboxyl-containing polyurethane, 15 parts of hydroxyl-terminated polyphenylene ether, 75 parts of biphenyl-type epoxy resin, 45 parts of phosphorus-containing epoxy resin, and 10 parts of butanone Parts were placed in a high-dispersion mixing tank and stirred for 2 hours;

[0051] Step 2: Mix and stir the mixture obtained in Step 1 with 5 parts of ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com