Water-based blocked isocyanate curing agent and preparation method thereof, water-based coating

A technology for blocking isocyanate and water-based coatings, applied in the field of coatings, can solve the problems of no obvious improvement in the thickness of the coating film, increase the production cost, and the thickness of the coating film. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Another embodiment of the present invention is to provide a method for preparing the above-mentioned water-based blocked isocyanate curing agent, which includes the following steps S1-S4.

[0065] S1. Hydrophilic modification and chain extension of polyethylene glycol monomethyl ether, polyether diol and polyisocyanate to obtain a urethane prepolymer.

[0066] In one embodiment, before the steps of hydrophilic modification and chain extension, the step of dehydrating polyethylene glycol monomethyl ether and polyether diol is also included, and the polyethylene glycol monomethyl ether is controlled to And the water content of the polyether diol is less than 0.1 wt%.

[0067] Further, the dehydration conditions include: the degree of vacuum is less than or equal to -0.099MPa, the temperature is 80°C-105°C, and the time is 0.5h-4h.

[0068] Preferably, the degree of vacuum is -0.1MPa˜-0.099MPa.

[0069] In one embodiment, the temperature for hydrophilic modification and ...

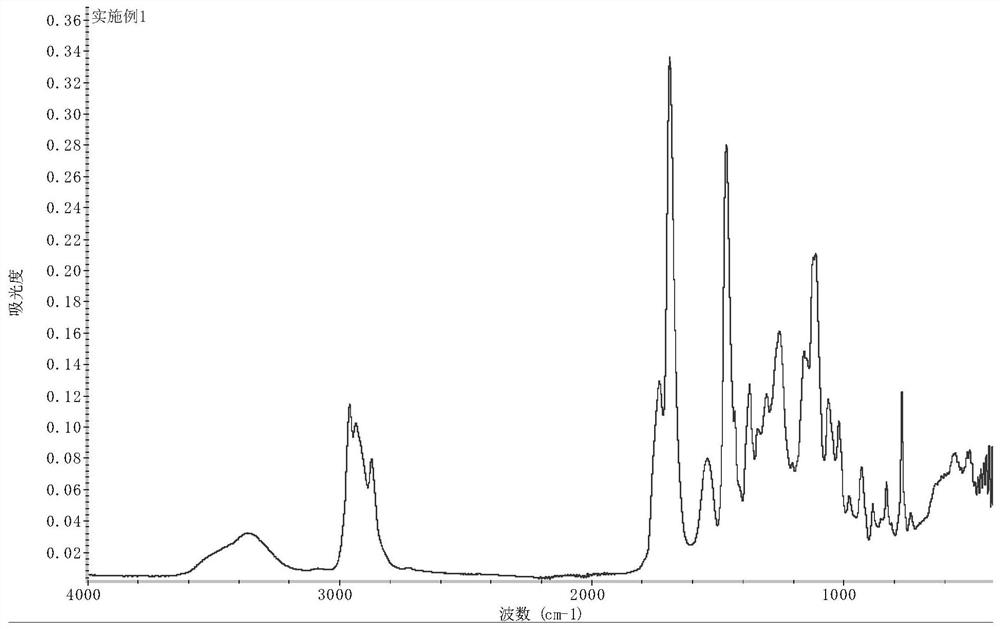

Embodiment 1

[0098] (1) Polyethylene glycol monomethyl ether (MPEG1000) and polyethylene glycol (PEG1000) are placed in a four-necked round bottom flask, and toluene is added (the amount of toluene is 10% of the weight of polyethylene glycol monomethyl ether) , insert a thermometer, then turn on the oil pump, remove water under reduced pressure (vacuum degree is -0.099MPa, temperature is 80°C, time is 4h), the water content of the end point control mixture is 0.07%, and cooled to 40°C.

[0099] (2) Install a reflux condenser, a thermocouple, a thermometer, and a nitrogen tube on the above-mentioned four-necked round-bottomed flask, and in a stirring state, add ethyl acetate (the consumption of ethyl acetate is 10% to 20% of the total volume of the reaction system) ), HDI trimer polyisocyanate, blowing in nitrogen at the same time, dispersing for 15min, then raising the temperature to 90°C, stopping blowing in nitrogen, and reacting for 2h to obtain a urethane prepolymer.

[0100] (3) Alkal...

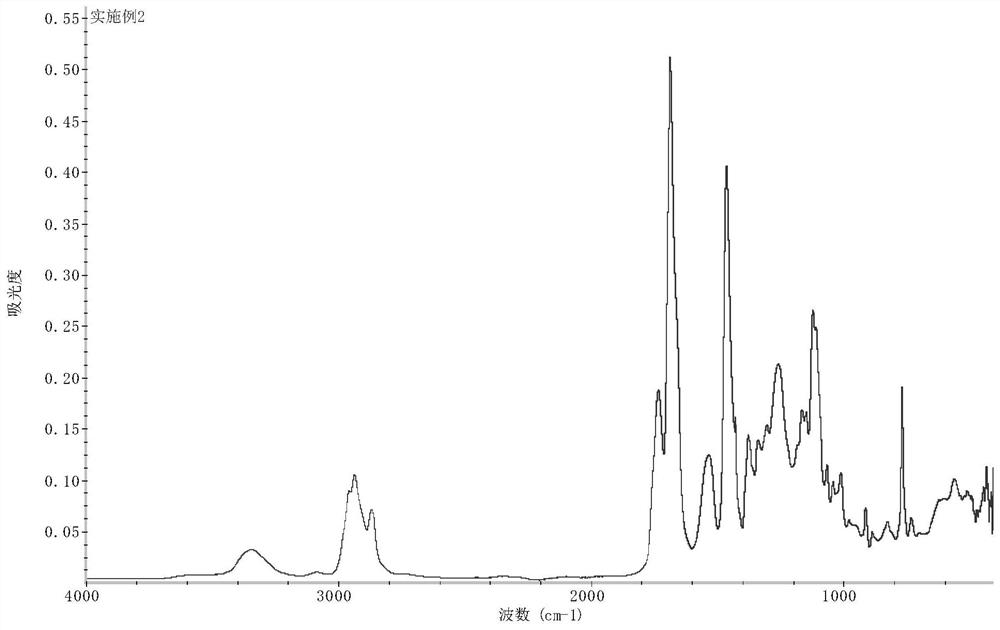

Embodiment 2

[0104] (1) Place polyethylene glycol monomethyl ether (MPEG300) and polyethylene glycol (PEG500) in a four-necked round-bottomed flask, add toluene (the amount is 10wt% of polyethylene glycol monomethyl ether), insert a thermometer , then turn on the oil pump, remove water under reduced pressure (vacuum degree is -0.099MPa, temperature is 99°C, time is 2h), the water content of the mixture is controlled at the end point to be 0.1%, and cooled to 40°C.

[0105] (2) Install a reflux condenser, a thermocouple, a thermometer, and a nitrogen pipe on the above-mentioned four-necked round-bottomed flask, add ethyl acetate and IPDI trimer polyisocyanate under stirring, blow into nitrogen simultaneously, disperse for 15min, and then Raise the temperature to 90°C, stop blowing nitrogen, and react for 2 hours to obtain a urethane prepolymer.

[0106] (3) Alkali metal salts of alcohols (potassium tert-butoxide) and malonate blocking agent (dimethyl malonate) were pre-dispersed at room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com