A kind of composite gel polymer electrolyte, its preparation method and application

A composite gel and polymer technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of affecting the performance of polymer electrolytes, weak interfacial interaction, and inability to give full play to the advantages, so as to improve the cycle Effects of safety, enhanced interaction, and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a kind of preparation method of above-mentioned composite gel polymer electrolyte, comprises the following steps:

[0045] A. Disperse the filler in the ionic liquid dispersant by means of stirring, and the ionic liquid dispersant is the second ionic liquid to obtain a uniformly dispersed second ionic liquid / filler dispersion system.

[0046] B. Add photoinitiator, crosslinking agent, lithium salt and first ionic liquid monomer into the second ionic liquid / filler dispersion system described in step A, stir and mix to obtain composite gel polymer electrolyte precursor; The photoinitiator is 2,4,6-(trimethylbenzoyl)diphenylphosphine oxide, 2,4,6-trimethylbenzoylphenylphosphonic acid ethyl ester, 2-hydroxy-2-methyl Base-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, 1-hydroxycyclohexylphenyl ketone and 2-methyl-2-(4-morpholinyl)-1- One or more of [4-(methylthio)phenyl]-1-propanone; the cross-linking agent is ethylene glycol dimethacrylate, 2,5-d...

Embodiment 1

[0051] Using molybdenum disulfide as a filler and 1-vinyl-3-butylimidazole-bistrifluoromethanesulfonimide salt as a monomer, prepare poly[1-vinyl-3-butylimidazole-bistrifluoromethanesulfonyl imide salt according to the following steps] Fluoromethanesulfonylimide salt] / molybdenum disulfide composite gel polymer electrolyte:

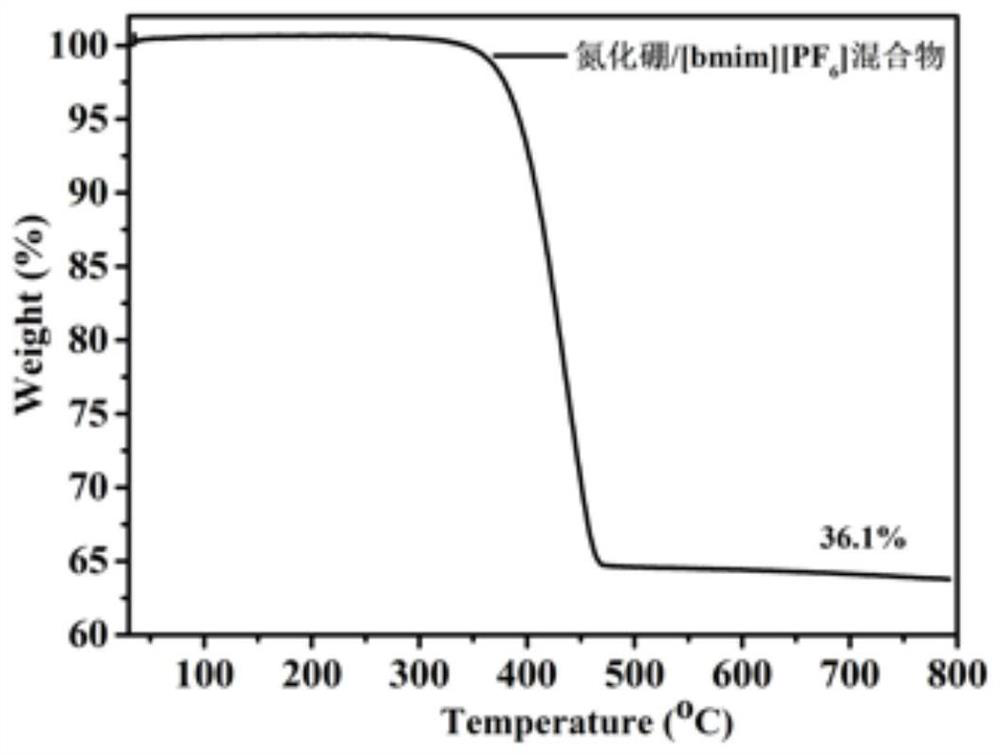

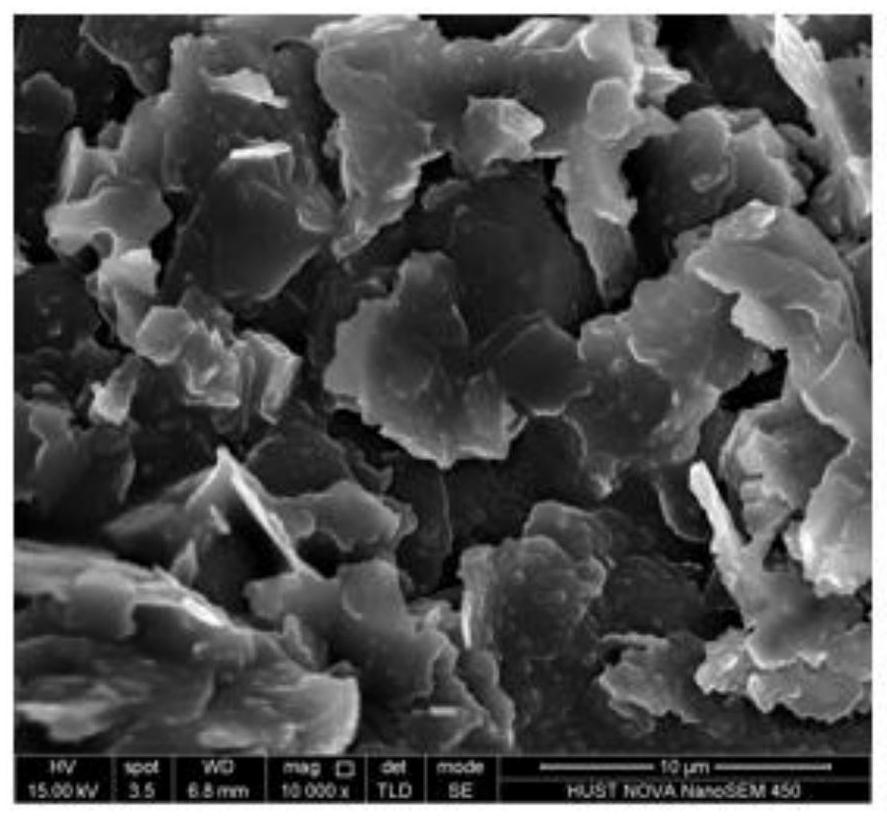

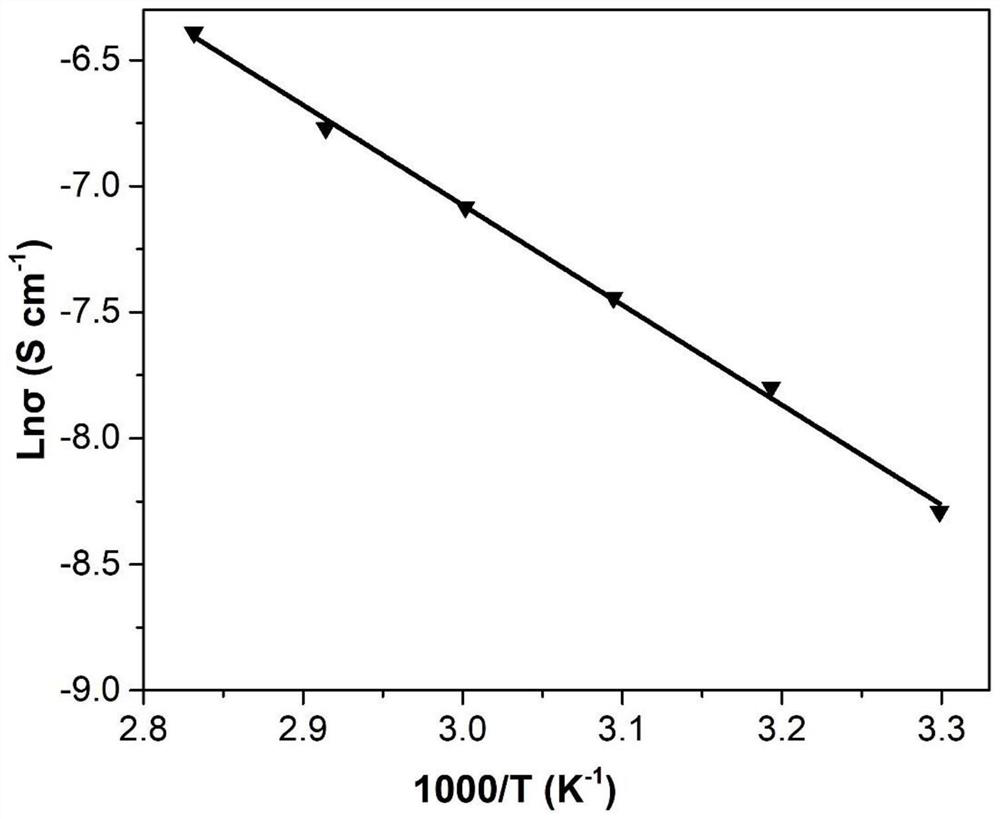

[0052] (1) 0.3 g of molybdenum disulfide, 60 ml of 1-ethyl-3-methylimidazole-hexafluorophosphate (EmimPF 6 ) of the round bottom flask was mechanically stirred and ultrasonically assisted to disperse for 8 hours to obtain a molybdenum disulfide-ionic liquid pre-dispersion. The molybdenum disulfide-ionic liquid pre-dispersion is subjected to centrifugation, and the obtained upper layer dispersion is subjected to vacuum filtration to obtain molybdenum disulfide / EmimPF 6 mixture. Determination of molybdenum disulfide / EmimPF by thermogravimetric analyzer 6 EmimPF in the mixture 6 Residual amount of ionic liquid, to molybdenum disulfide / EmimPF 6 Add EmimPF...

Embodiment 2

[0060] Using graphene as a filler and 1-vinyl-3-butylimidazole-bistrifluoromethanesulfonimide salt as a monomer, prepare poly[1-vinyl-3-butylimidazole-bistrifluoromethanesulfonyl imide according to the following steps Methanesulfonylimide salt] / graphene composite gel polymer electrolyte:

[0061] (1) The round-bottomed flask of 0.3 gram of graphene and 60 milliliters of 1-butyl-3-methylimidazole-bistrifluoromethanesulfonimide salt (BmimTFSI) is mechanically stirred and ultrasonically assisted to disperse 8 Hour, obtain graphene-ionic liquid predispersion liquid. The graphene-ionic liquid pre-dispersion liquid is subjected to centrifugation, and the obtained upper layer dispersion liquid is then vacuum-filtered to obtain a graphene / BmimTFSI mixture. Determine the residual amount of BmimTFSI ionic liquid in the graphene / BmimTFSI mixture by thermogravimetric analysis, add BmimTFSI ionic liquid to the graphene / BmimTFSI mixture, and obtain a uniformly dispersed BmimTFSI / graphene d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com