Magnesium alloy with high strength and ductility and high electromagnetic shielding performance and thermo-mechanical treatment method thereof

A deformation heat treatment and electromagnetic shielding technology, applied in the field of magnesium alloys with high strength and toughness and high electromagnetic shielding performance and the field of deformation heat treatment, can solve the problems of inability to have both strength and toughness and electromagnetic shielding performance, improving electromagnetic shielding performance, and insufficient electromagnetic shielding performance. , to achieve the effect of improving electromagnetic shielding performance, increasing purity, and weakening the intensity of electromagnetic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

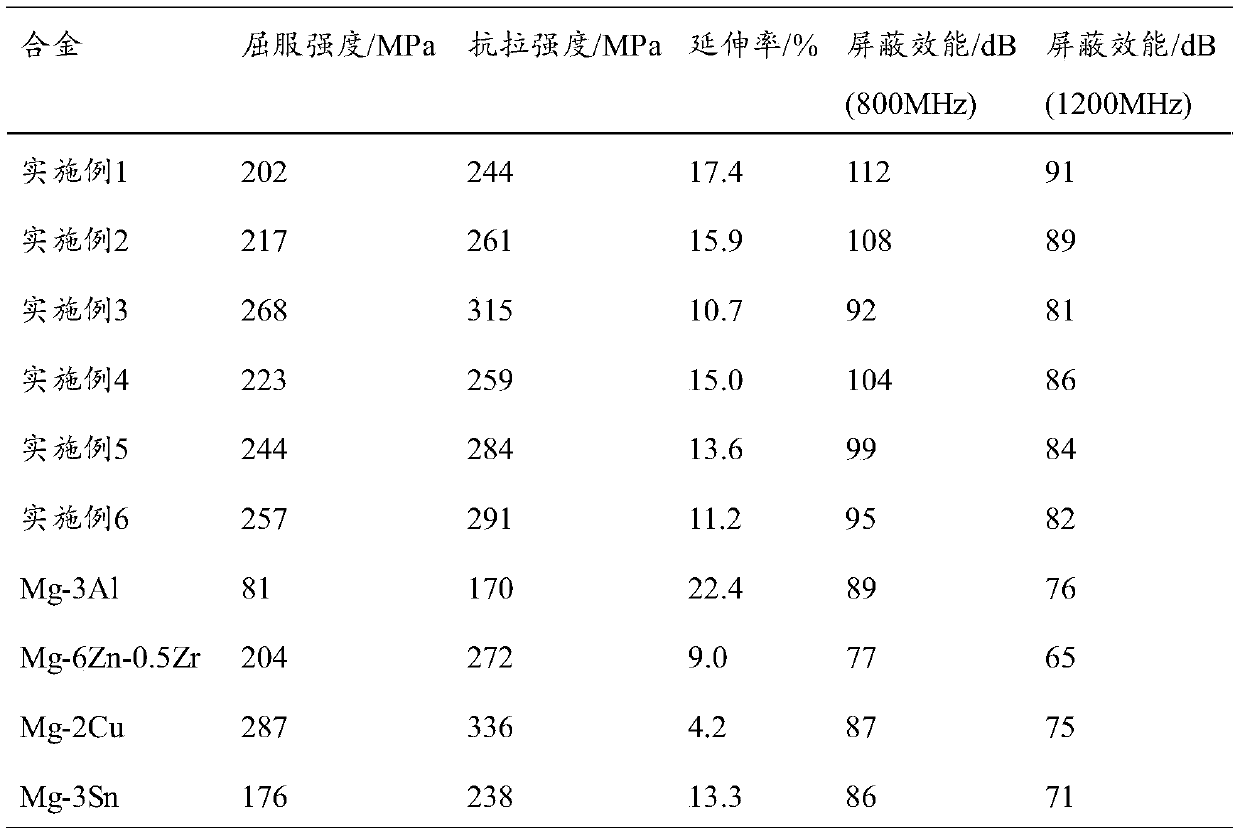

Embodiment 1

[0023] The raw material is Mg-3Gd-0.6Ca-0.2Zn alloy (mass percentage), and the mass ratio of Ca / Zn is 3. Semi-continuous casting and hot rolling are used to obtain a plate with a thickness of 10mm. 72h of aging treatment, water quenching, then, at 80 °C for deformation with a true strain of 0.03, and then 190 °C for 48h of aging treatment and water quenching. The mechanical properties and electromagnetic shielding properties of the alloy were tested at room temperature, and the results are shown in Table 1.

Embodiment 2

[0025] The raw material is Mg-6Gd-0.8Ca-0.1Zn alloy (mass percentage), and the mass ratio of Ca / Zn is 8. The plate with a thickness of 20mm is obtained by semi-continuous casting and hot extrusion. The aging treatment and water quenching were carried out for 60 hours, and then, the deformation with a true strain of 0.07 was carried out at 60 °C, and the aging treatment and water quenching were carried out at 220 °C for 24 hours. The mechanical properties and electromagnetic shielding properties of the alloy were tested at room temperature, and the results are shown in Table 1.

Embodiment 3

[0027] The raw material is Mg-16Gd-0.2Ca-0.02Zn alloy (mass percentage), and the mass ratio of Ca / Zn is 10. A plate with a thickness of 25mm is obtained by semi-continuous casting and hot rolling. 2h of aging treatment, water quenching, then, at room temperature, the deformation of the true strain is 0.1, and then 1h of aging treatment and water quenching at 150 °C. The mechanical properties and electromagnetic shielding properties of the alloy were tested at room temperature, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com