Preparation method and application of flaky nano copper oxide

A nano-copper oxide and flake technology is applied in the field of preparation of flake nano-copper oxide, which can solve the problems of increasing the production cost of copper oxide, affecting the photocatalytic performance, harming the production personnel and the like, achieving good heat exchange, convenient temperature adjustment, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

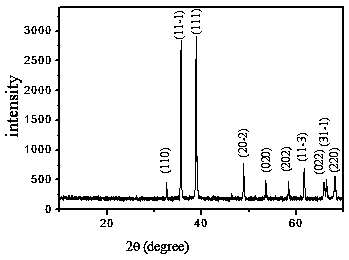

Image

Examples

preparation example Construction

[0035] A preparation method of flaky nano-copper oxide, comprising the following steps:

[0036] S1, accurately weigh copper salt and oxalic acid or oxalate, the molar ratio of the copper salt and the oxalic acid or oxalate is 1:0.8-1.2, preferably the molar ratio of copper salt and oxalic acid or oxalate is 1:1.05; the copper salt is one of copper chloride dihydrate and copper sulfate pentahydrate, the oxalic acid is oxalic acid dihydrate, and the oxalate is ammonium oxalate monohydrate; the copper chloride dihydrate, copper sulfate pentahydrate, Oxalic acid dihydrate and ammonium oxalate monohydrate are analytical grade raw materials.

[0037] S2, mix the copper salt weighed in S1 with oxalic acid or oxalate evenly and grind for 5-30 minutes, then add an appropriate amount of distilled water several times to make the mixture in a fluid state during grinding, and then grind for 0.5-1h; adding water is because in During the grinding process, the water will continue to evapora...

Embodiment 1

[0045] A preparation method of flaky nano-copper oxide, comprising the following steps:

[0046] S1, accurately weigh 8.5250g (0.0500moL) of copper chloride dihydrate and 6.6150g (0.0525moL) of oxalic acid dihydrate, so that the molar ratio of copper chloride dihydrate and oxalic acid dihydrate is 1:1.05;

[0047] S2, mix copper chloride dihydrate and oxalic acid dihydrate weighed in S1 evenly, grind for 10 minutes, then add appropriate amount of distilled water several times to keep the mixture in a fluid state during grinding, and then grind for 0.7 h;

[0048] S3, put the ground fluid mixture in S2 into a reactor, put the reactor into an oven and heat for 4 hours, and the temperature of the oven is 60°C;

[0049] S4, suction-filtering the mixture heated in S3, and then cleaning the filter cake with distilled water until there are no chloride ions in the filtrate, and then cleaning the filter cake with absolute ethanol for 1-2 times;

[0050] S5, put the filter cake cleaned...

Embodiment 2

[0056] A preparation method of flaky nano-copper oxide, comprising the following steps:

[0057] S1, accurately weigh 8.5250g (0.0500moL) of copper chloride dihydrate and 5.0400g (0.0400moL) of oxalic acid dihydrate, so that the molar ratio of copper chloride dihydrate and oxalic acid dihydrate is 1:0.8;

[0058] S2, mix the copper chloride dihydrate and oxalic acid dihydrate weighed in S1 evenly and grind for 5 minutes, then add an appropriate amount of distilled water several times to make the mixture in a fluid state during grinding, and then grind for 0.5 h;

[0059] S3, put the ground fluid mixture in S2 into a reactor, put the reactor into an oven and heat for 2 hours, and the temperature of the oven is 80°C;

[0060] S4, suction-filtering the mixture heated in S3, and then cleaning the filter cake with distilled water until there are no chloride ions in the filtrate, and then cleaning the filter cake with absolute ethanol for 1-2 times;

[0061] S5, putting the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com